Rapid bending forming device of multi-angle sheet metal parts and forming method of rapid bending forming device

A technology for bending and forming, sheet metal parts, applied in the field of sheet metal, can solve the problems of mold waste, time reduction and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

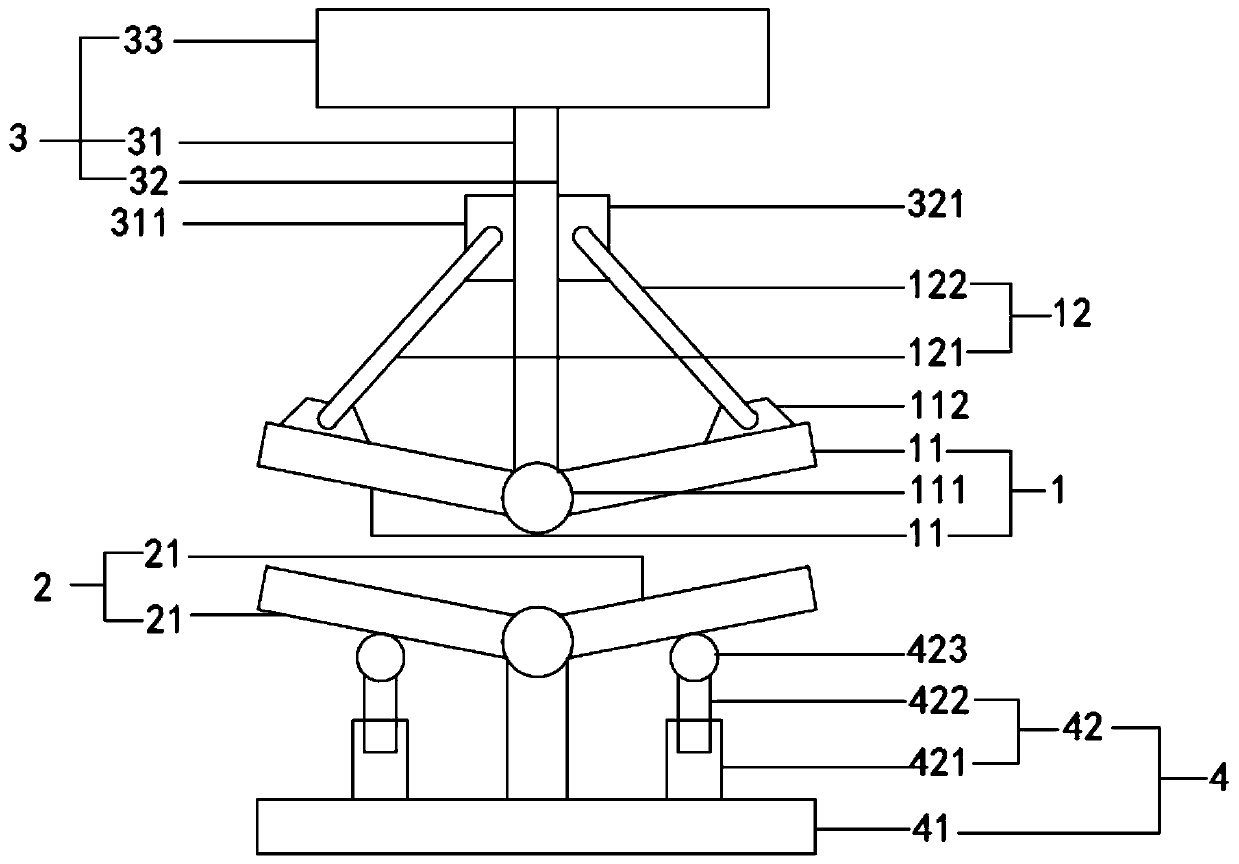

[0024] see Figure 1 to Figure 2 , the figure shows a rapid bending and forming device for multi-angle sheet metal parts provided by Embodiment 1 of the present invention. First, a mold is set up, which includes an upper mold 1 and a lower mold 2. The upper mold 1 includes two hinged parts The first template 11 of the first template 11, the hinged ends 111 of two first templates 11 are connected to the end of the first elevating mechanism 3, and the first elevating mechanism 3 includes the first guide rail 31, the second guide rail 32 and the motor 33, the first guide rail 31 The first slider 311 is slidably installed on the upper side, and the second slider 321 is slidably installed on the second guide rail 32. The ends of the two first templates 11 are respectively connected to the first slider 311 and the second slider through the transmission rod assembly 12. The block 321, the first slide block 311 and the second slide block 321 all slide under the drive of the motor 33, ...

Embodiment 2

[0029] see Figure 1 to Figure 2 , the figure shows a rapid bending and forming device for multi-angle sheet metal parts provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements The upper mold 1 includes two first templates 11 hinged to each other, the hinged ends 111 of the two first templates 11 are connected to the end of the first lifting mechanism 3, and the first lifting mechanism 3 includes a first guide rail 31, a second guide rail 32 and a motor 33, the first slide block 311 is slidably installed on the first guide rail 31, the second slide block 321 is slidably installed on the second guide rail 32, and the ends of the two first templates 11 are respectively connected to the drive plate assembly 12. The first sliding block 311 and the second sliding block 321 have higher strength than the driving rod as compared with the first embodiment, and can...

Embodiment 3

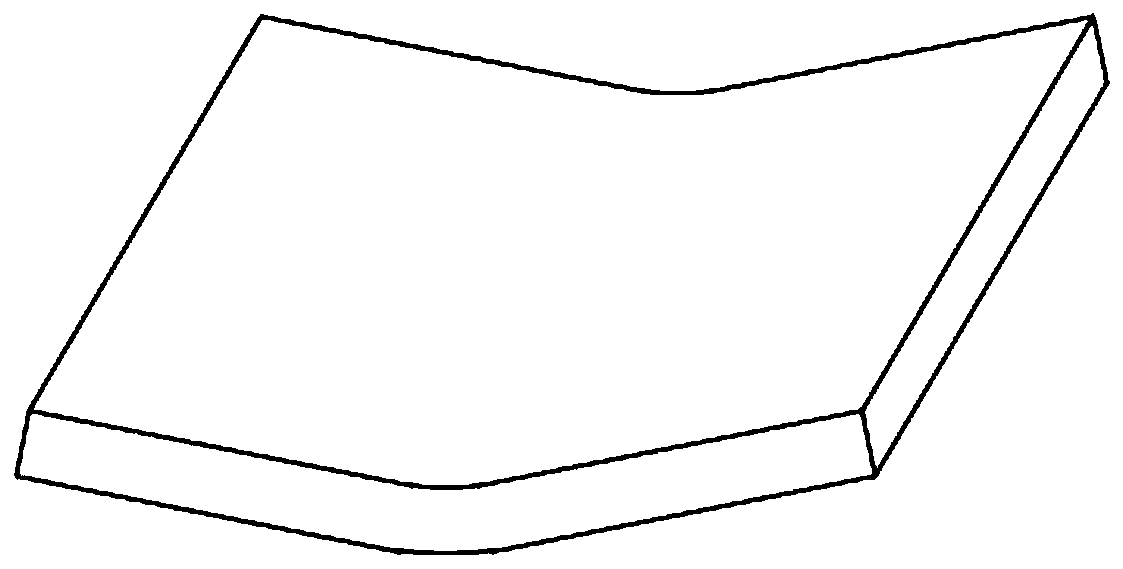

[0031] see Figure 1 to Figure 2 , the figure shows a rapid bending and forming device for multi-angle sheet metal parts provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements The lower mold 2 includes two second templates 21 hinged to each other, the second template 21 is installed on the second lifting mechanism 4, the upper surface of the lower mold 2 is equipped with an ejection mechanism, and the ejection mechanism includes two elastically connected plates, It is tightly attached to the surface of the lower mold 2 under the pressing action of the upper mold 1. After the sheet metal part is formed, the upper mold 1 is released, and the two elastically connected plates return to their original shape under the action of the elastic force, and then the formed sheet metal The top of the piece is separated from the lower mold 2, which is convenient for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com