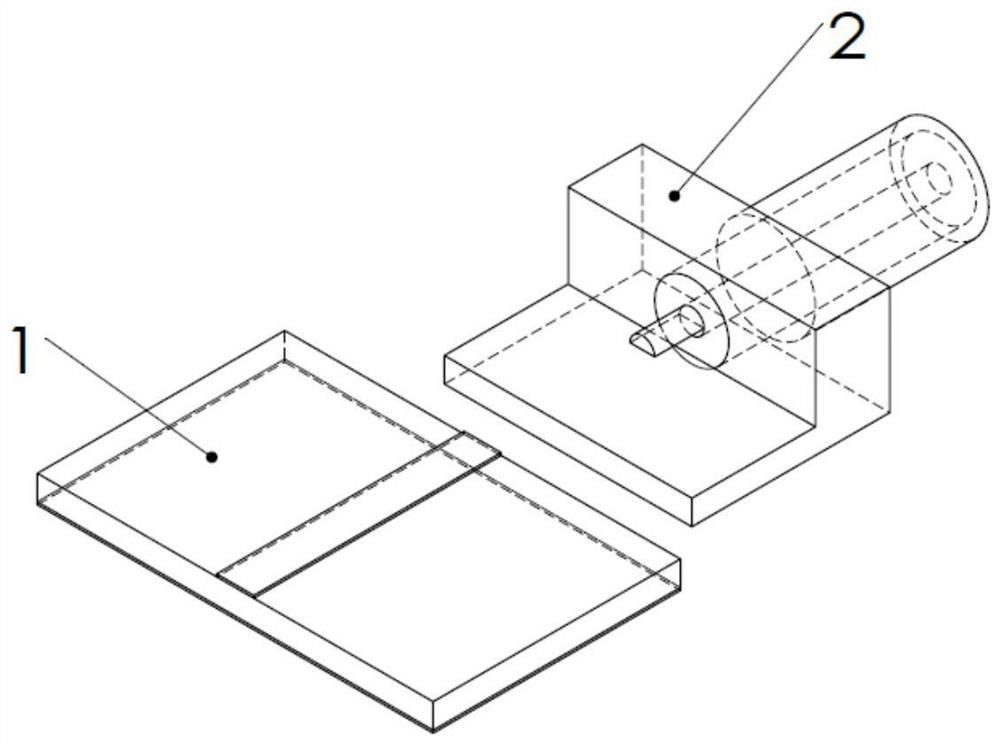

A Semi-coaxial Microstrip Combination RF Transmission Line Structure

A coaxial transmission line, radio frequency transmission technology, applied in the field of radio frequency microwave, can solve the problems of "probe" breakage, weakened structural strength, and small "probe" diameter, and achieves low assembly and disassembly operation difficulty, reliability and high reliability. The effect of improved stability and easy batch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

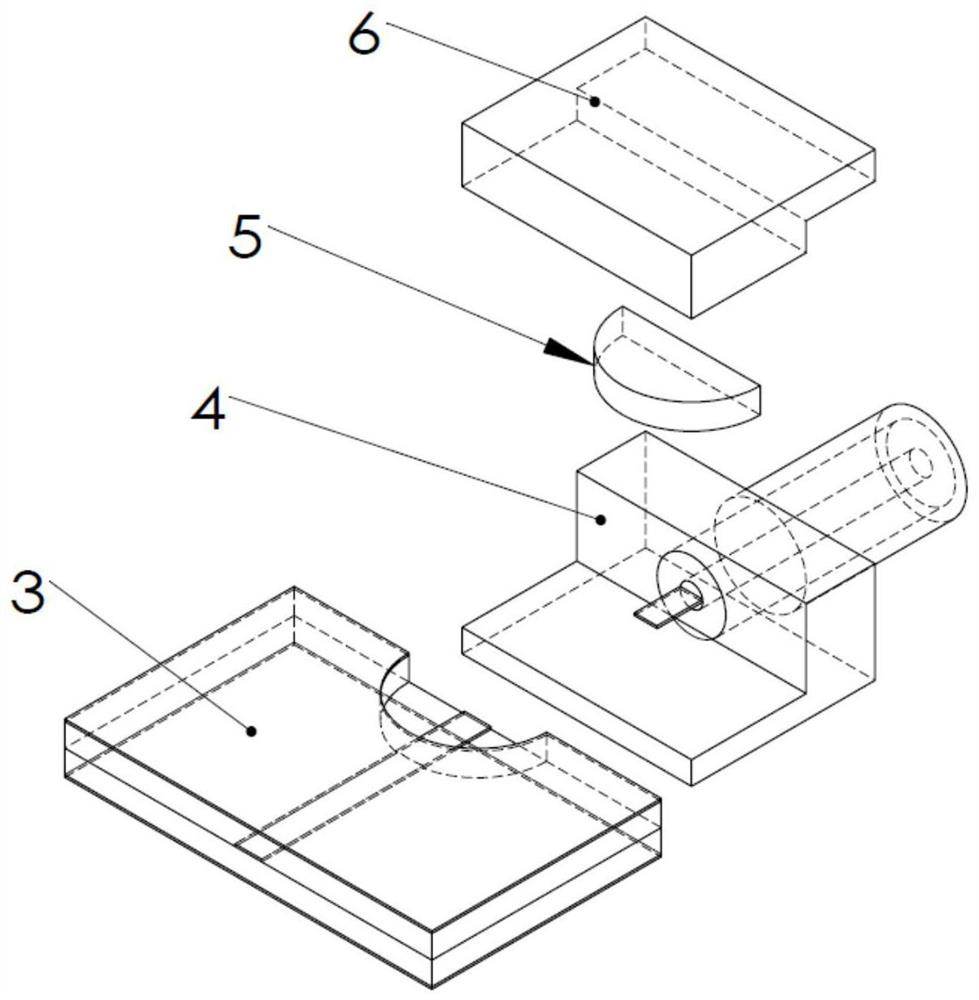

Method used

Image

Examples

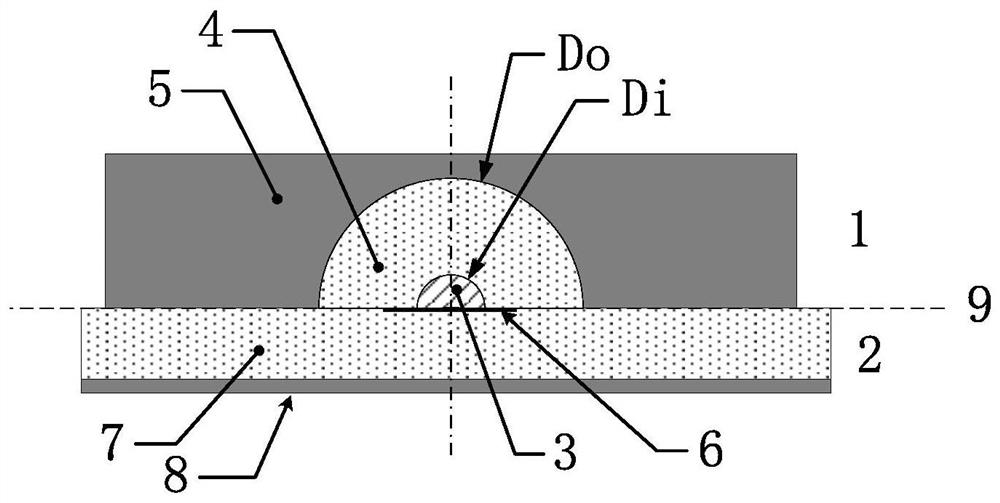

Embodiment 1

[0034] Implementation example 1: see Figure 6 , this example provides a design solution for a horizontal crimping RF connector installed on a microstrip line, including three parts: the microstrip line 1 to be installed, the microstrip crimping connector 17 and the metal pressing block 6 . The coaxial inner diameter of the microstrip crimp connector 17 is 1 mm, the coaxial medium is polytetrafluoroethylene, the dielectric constant is 2.08, and the outer diameter is 3.3 mm when the calculated characteristic impedance is 50 ohms. Extend half of the coaxial conductor, medium and outer conductor by 5 mm through the axis in the horizontal direction to obtain a semi-coaxial 7. The substrate thickness of the microstrip line 1 is 1 mm, the dielectric constant is 2.55, and the width of the microstrip line corresponding to a calculated characteristic impedance of 50 ohms is 2.8 mm. The matching microstrip 8 is located at the end of the microstrip line 1 and has the same length as the ...

Embodiment 2

[0035] Implementation example 2: change and obtain on the basis of example 1, refer to Figure 7 . The medium of the stripline 3 is formed by gluing two substrates together, with a total thickness of 2.1 mm and a dielectric constant of 2.55. The calculated characteristic impedance is 50 ohms and the corresponding center conduction strip width is 1.46 mm. A 5mm×5mm groove is opened at the end to expose the central conduction band, corresponding to a substrate thickness of 1mm, and the width of the central conduction band line of the matching microstrip 8 determined from Example 1 when the characteristic impedance is 50 ohms is 1.24mm. Cut the semi-coaxial 7 part of the ribbon crimp connector 22 into a step of 5 mm x 5 mm with a height of 1.1 mm, and the outer conductor of the part below the step extends outward by 2 mm. During assembly, under the action of the metal pressing block 6, the lower ground layer forms a continuous grounding plane with the outer conductor and the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com