Visual packaging work system

A working system and packaging technology, applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems of restricting students' hands-on operation ability, robot teaching stays on books, etc., and achieve the effect of improving hands-on operation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

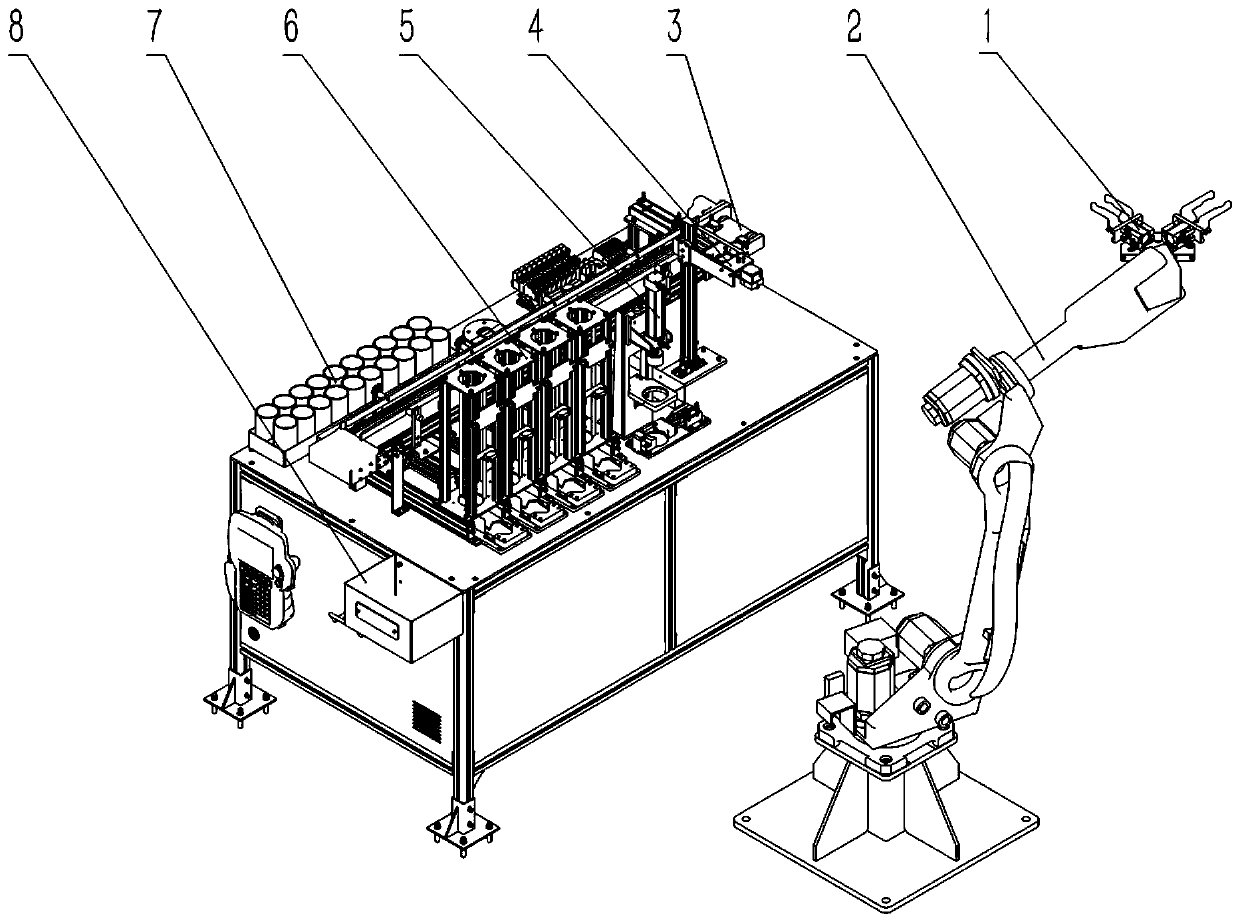

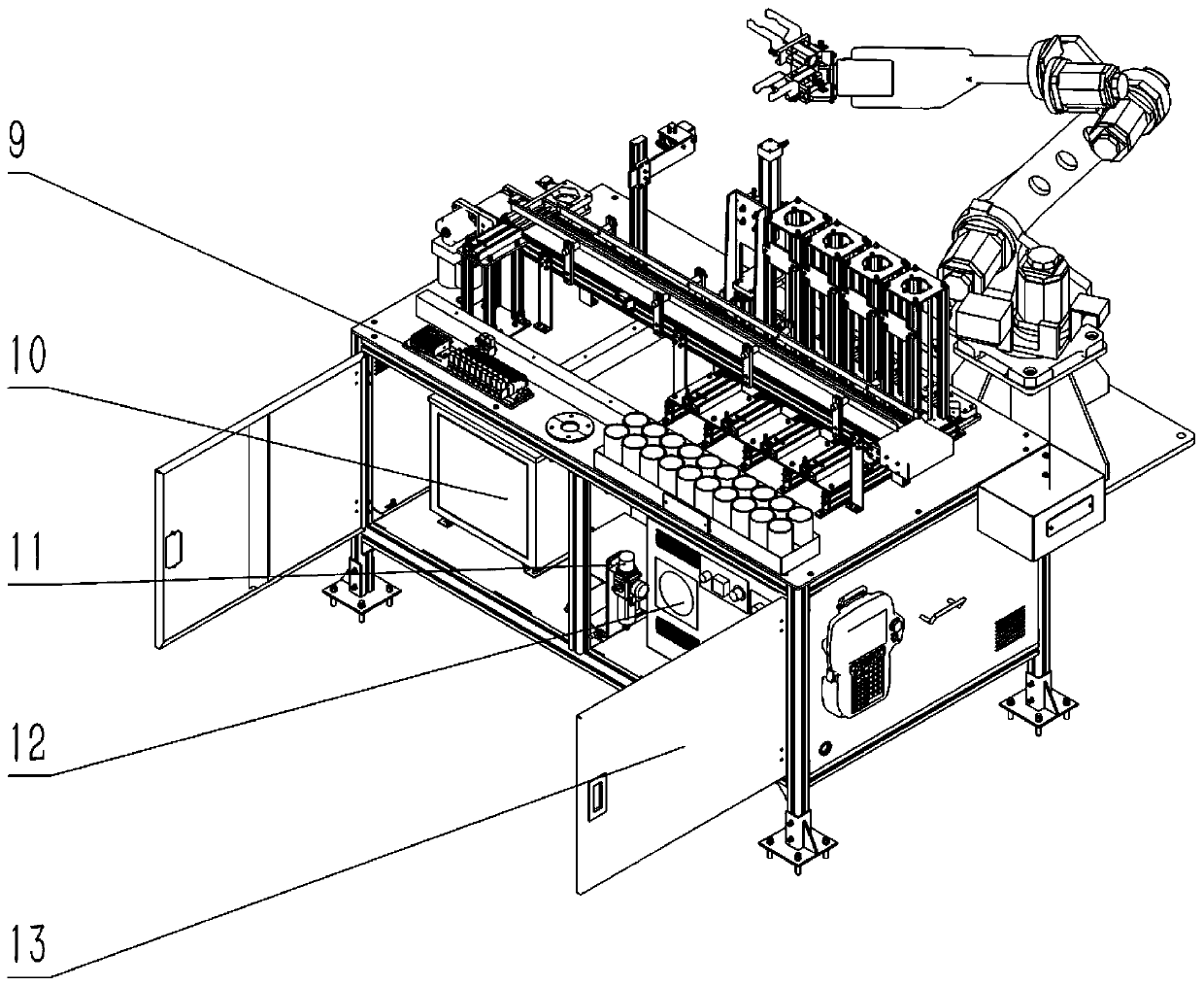

[0018] Such as Figure 1-2 As shown, a visual packaging work system includes a workbench cabinet (13), and a bottle feeding unit (3), a visual inspection unit (4), and a capping unit ( 5), bottle cap storage unit (6), bottle storage bin (7), waste recycling bin (8) and pneumatic control unit (9);

[0019] In the aforementioned industrial robot visual packaging system, the industrial robot control cabinet (13) is connected to the industrial robot (2), and the industrial robot (2) is controlled by the industrial robot control cabinet (12);

[0020] The robot transformer (10) provides suitable voltage and current for the robot.

[0021] After the external air source passes through the pressure regulating filter of the air source filtering unit (11) to filter the moisture in the air and adjust the pressure, it is output to the air circuit control unit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com