Method and system for variable displacement engine diagnostics

An engine and actuation technology, applied in the direction of engine components, combustion engine, engine control, etc., can solve the problem that the fuel injection timing cannot be set correctly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

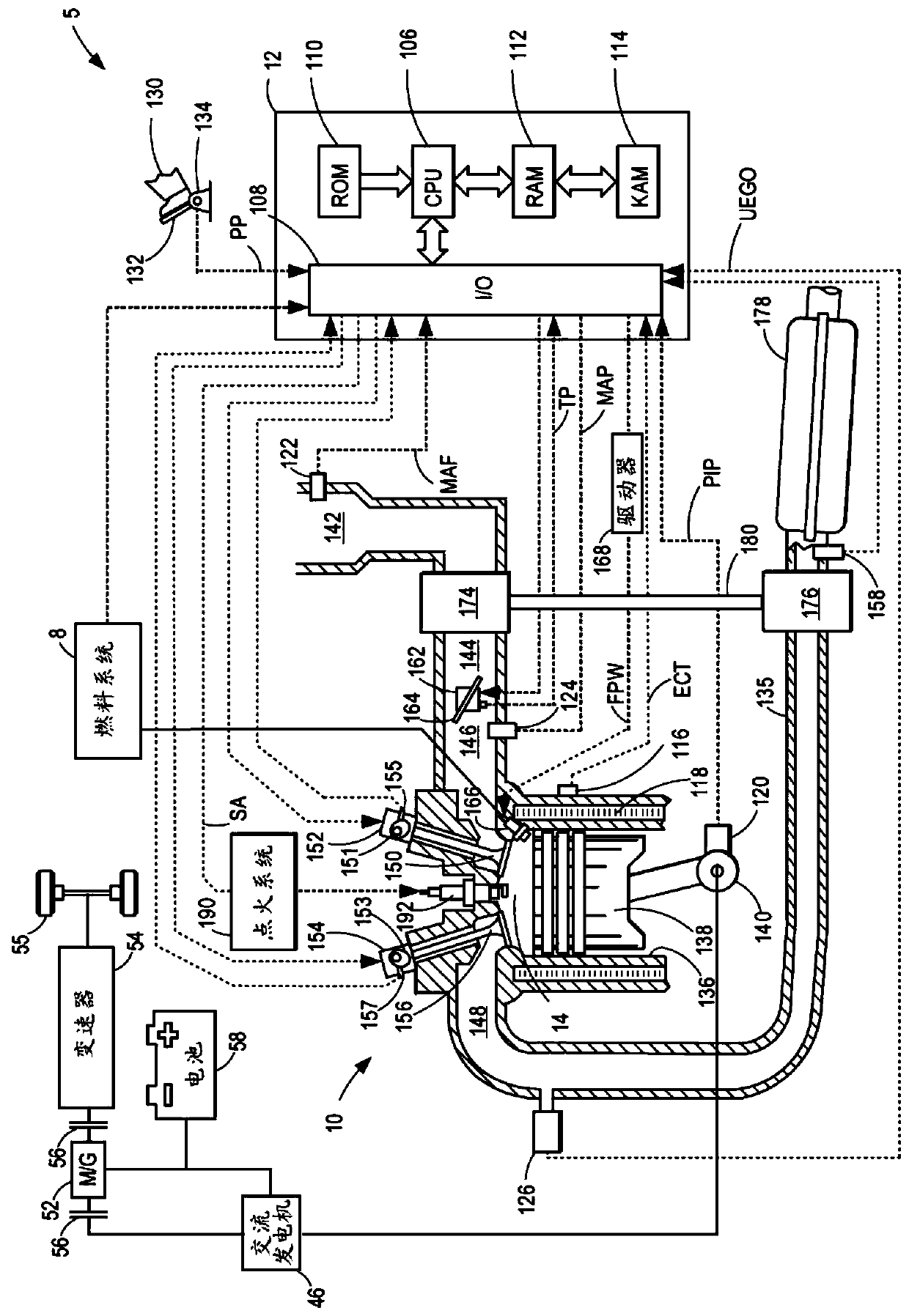

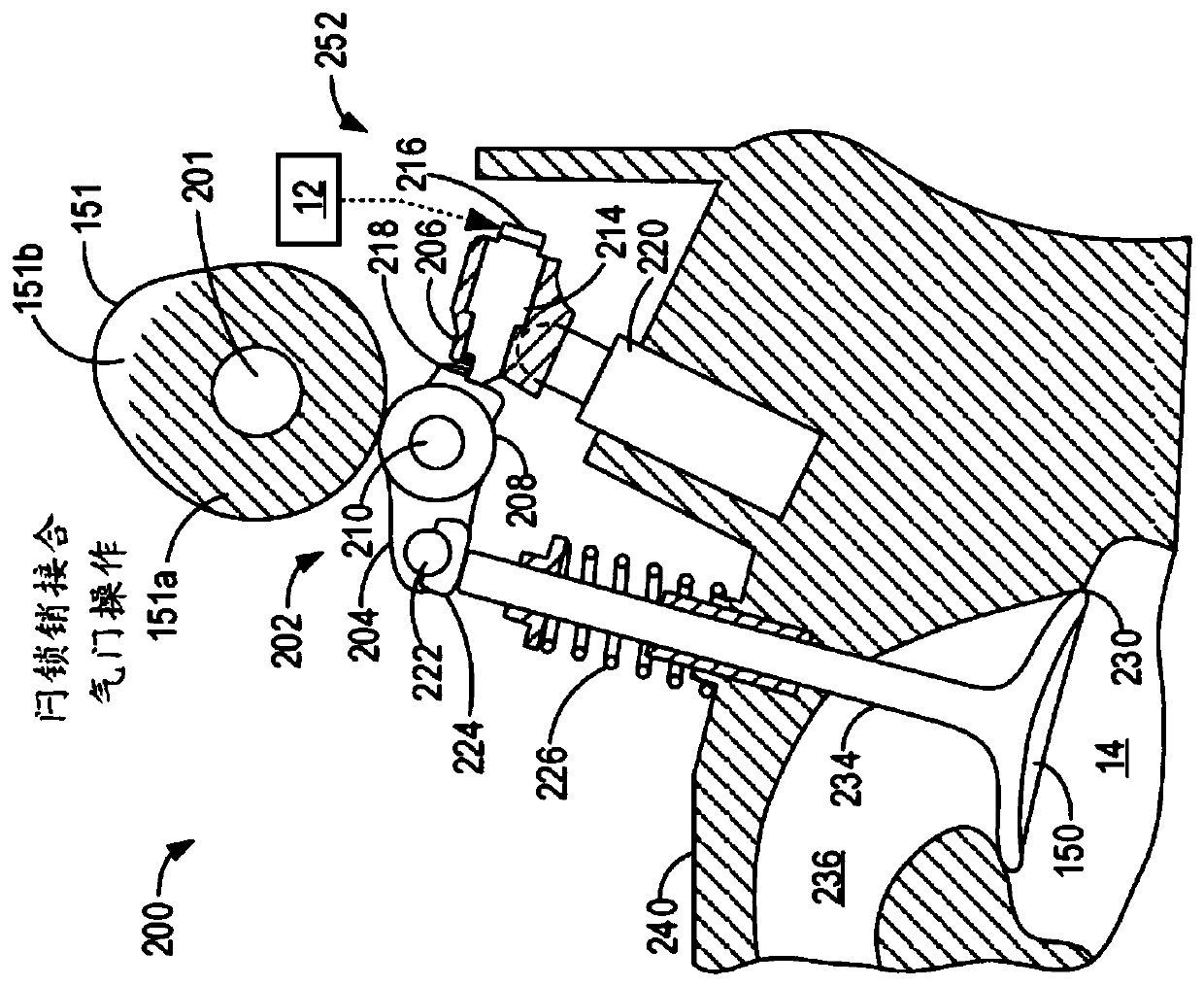

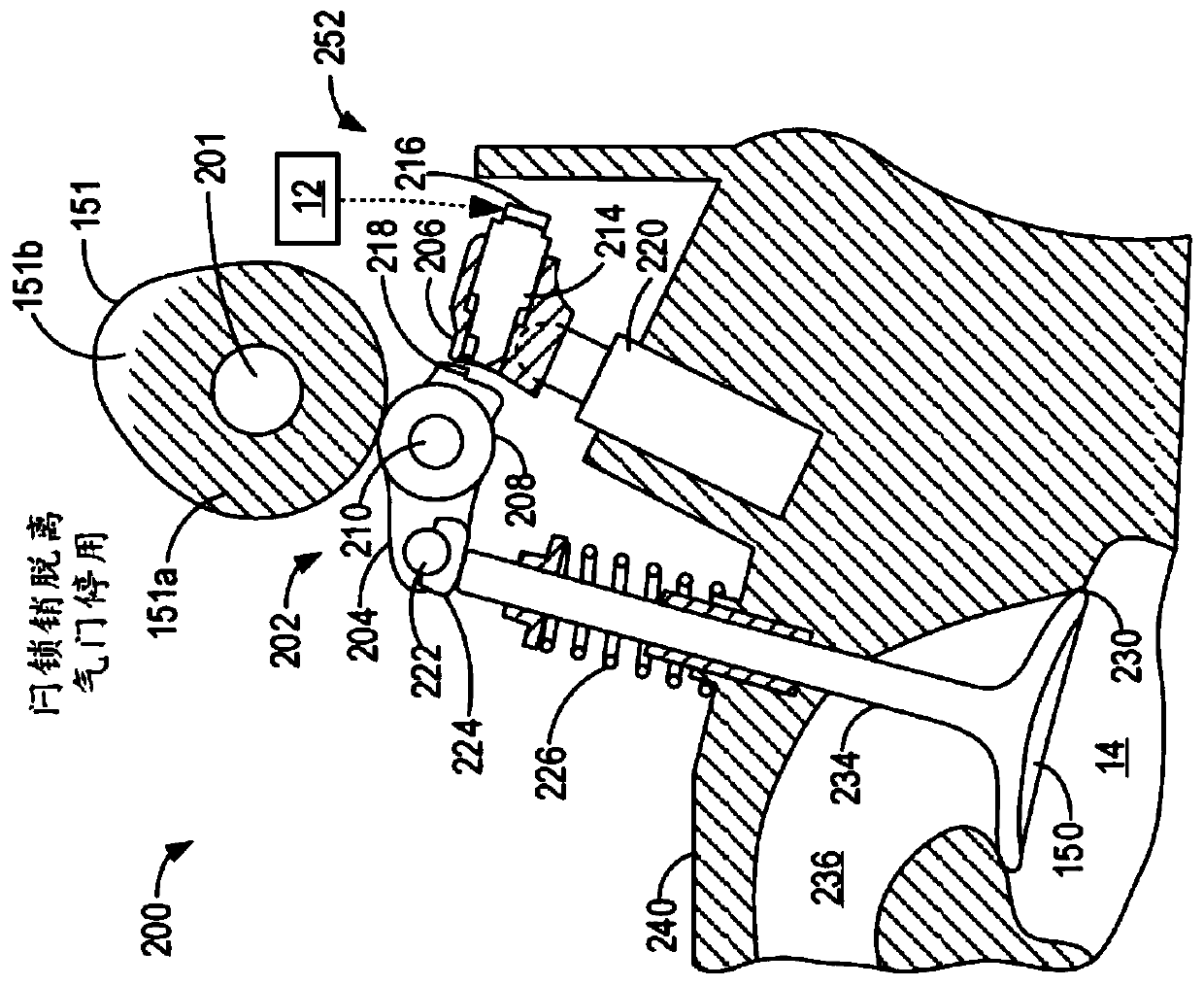

[0024] The following description relates to controls for engines (eg, figure 1 A system and method for a cylinder valve deactivation mechanism of an engine system). The cylinder valve deactivation mechanism may include an electrically latched rocker arm mechanism, such as in 2A to 2D Electric latch rocker mechanism depicted in . For example, by actuating a latch pin of the valve deactivation mechanism between an engaged position and a disengaged position via energizing an associated solenoid, the corresponding cylinder valve may be placed between an active state and a deactivated state switch, as in image 3 summarized in the table. For example, according to Figure 4 method and about Figure 11 To illustrate, the latch pin position, and thus the valve state, may be changed during engine start-up or shut-down, and, for example, according to Figure 5 method, the latch pin position and thus the valve state may be changed during transitions to and from a variable displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com