Rock mass quality continuous evaluation method and system by using drill core

A technology for rock mass quality evaluation and rock mass quality, which is applied in material analysis, measuring devices, and earthwork drilling and mining through optical means, and can solve discontinuity, insufficient utilization of drilling cores, locality of evaluation results, etc. problems, achieve the effect of realizing intelligence, long-term preservation and scientific management, and important engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

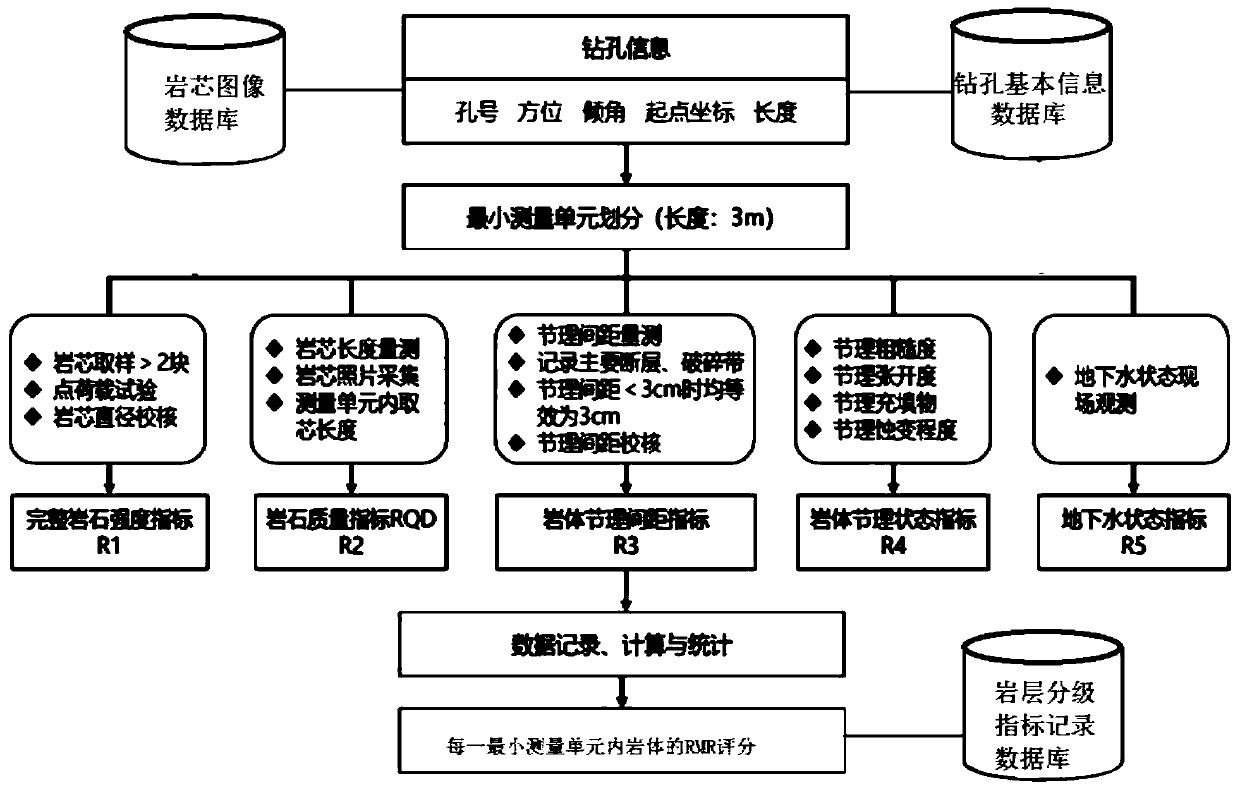

[0050] This embodiment provides a method for continuously evaluating rock mass quality by using drilled cores. The method collects digital core data, divides the minimum measurement range, measures and obtains grading indicators, and performs statistical scoring to realize the visualization of grading results.

[0051] Please refer to the attached figure 1 , the steps of the method for continuously evaluating rock mass quality using the drilled core include:

[0052] S101. Obtain drilling information and core image information, and establish a basic drilling information database and a core image database.

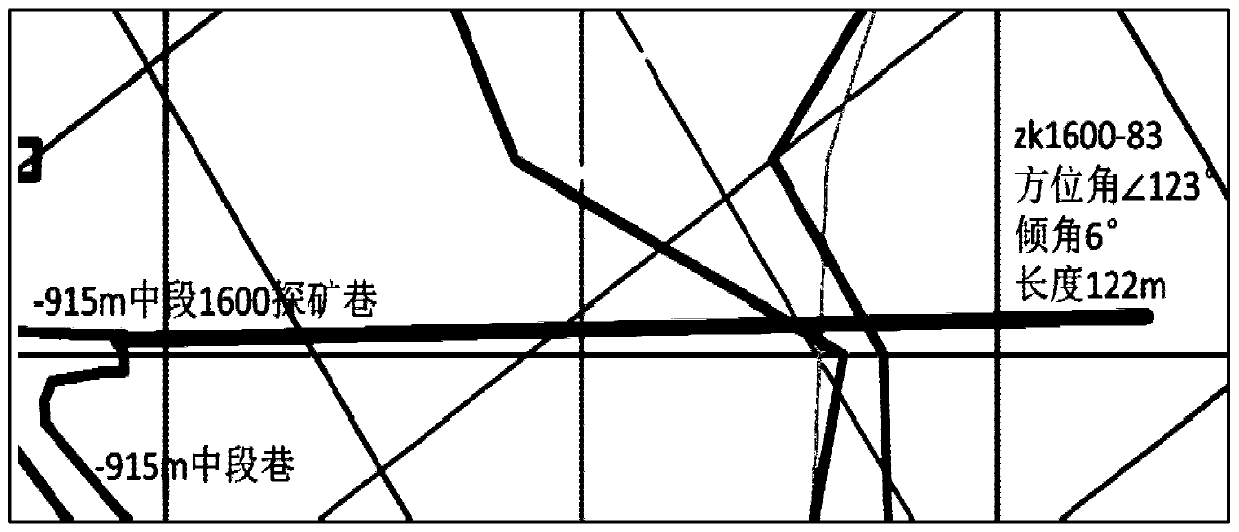

[0053] Please refer to the attached figure 2 , the drilling information includes the drilling number, azimuth, inclination, starting point coordinates and length, etc. The drill hole information is stored in the drill hole basic information database, which is convenient for the classification index to correspond to its real position in space after the rock mass classific...

Embodiment 2

[0096] The present embodiment provides a system for continuously evaluating rock mass quality using drilled cores, the system comprising:

[0097] The data acquisition module is used to obtain drilling information and core image information, and establish a basic drilling information database and a core image database;

[0098] The minimum measurement range division module is used to set the minimum measurement range and divide the entire drilling length range into multiple minimum measurement ranges;

[0099] The grading index calculation module is used to calculate the rock mass quality grading index within each minimum measurement range, and establish a rock formation grading index record database;

[0100] Scoring statistics module, used for scoring and summing all rock mass quality grading indicators in each minimum measurement range based on the RMR rock mass quality grading standard, to obtain all rock mass quality evaluation results in each minimum measurement range; ...

Embodiment 3

[0103] This embodiment provides a computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the following steps are implemented:

[0104] Obtain drilling information and core image information, and establish a database of basic drilling information and a database of core images;

[0105] Set the minimum measurement range and divide the entire drilling length range into multiple minimum measurement ranges;

[0106] Calculate the rock mass quality classification index within each minimum measurement range, and establish a rock formation classification index record database;

[0107] Based on the RMR rock mass quality classification standard, all rock mass quality classification indicators in each minimum measurement range are scored and summed to obtain all rock mass quality evaluation results in each minimum measurement range;

[0108]Based on the two-dimensional cloud image and the three-dimensional image, the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com