Drilling boom and rock drilling rig

A drilling and cantilever technology, which is applied in drilling equipment, drilling equipment and methods, and earth-moving drilling and mining, etc., to achieve the effects of improving stretchability, good stretchability, and durable weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

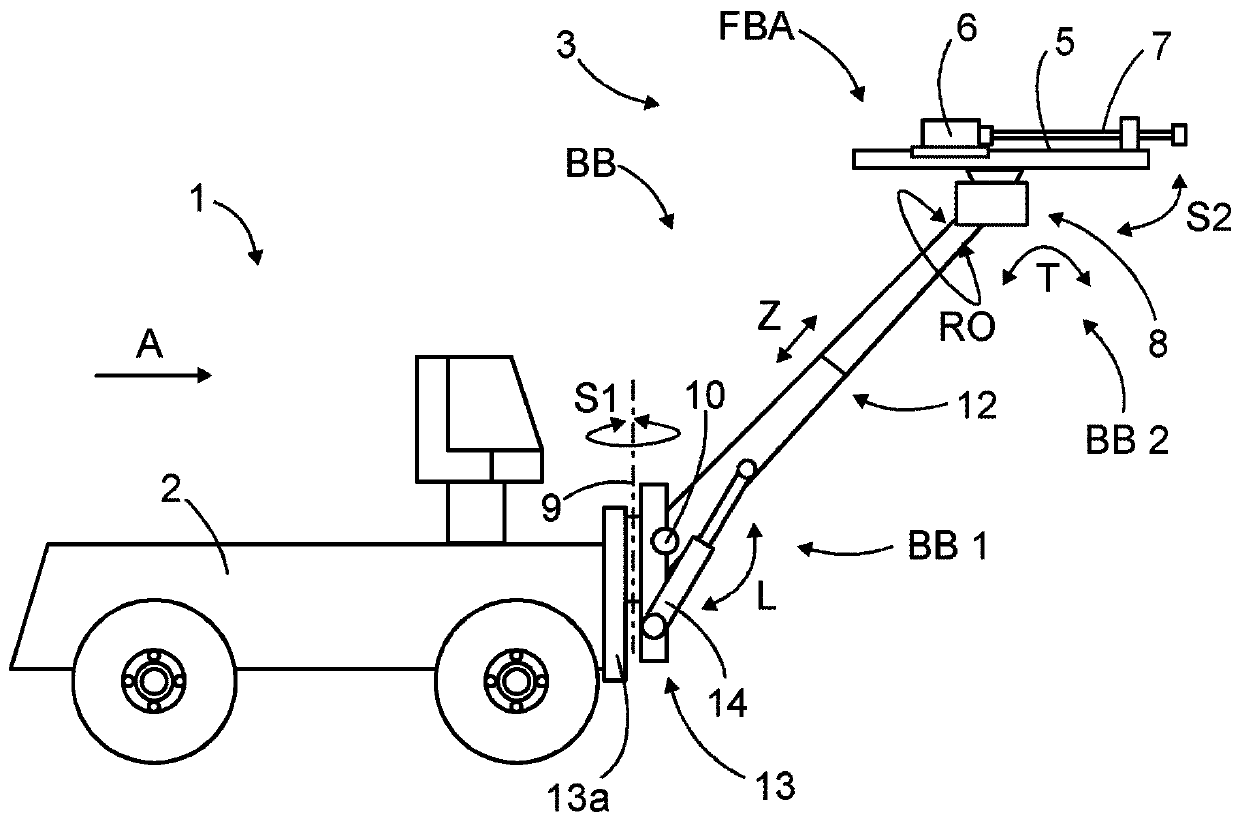

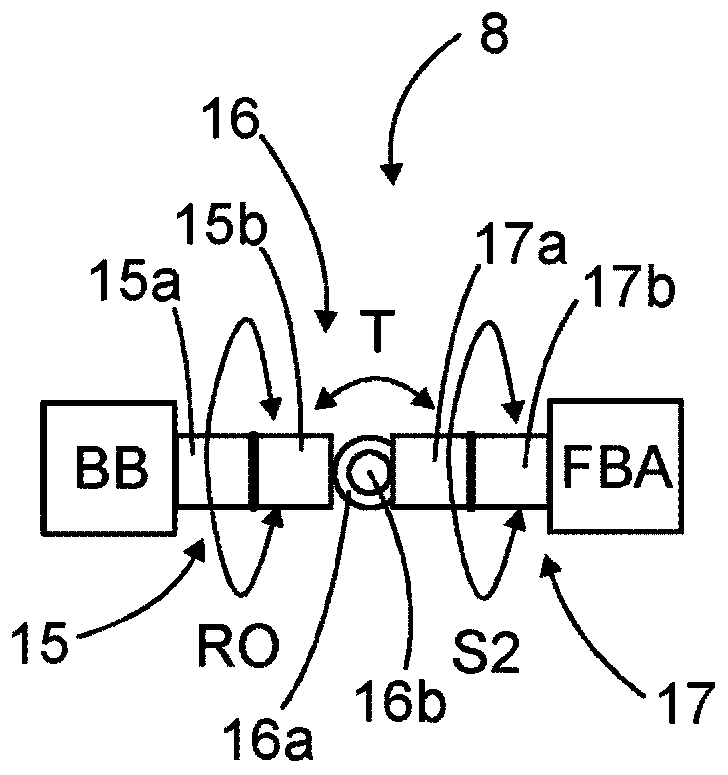

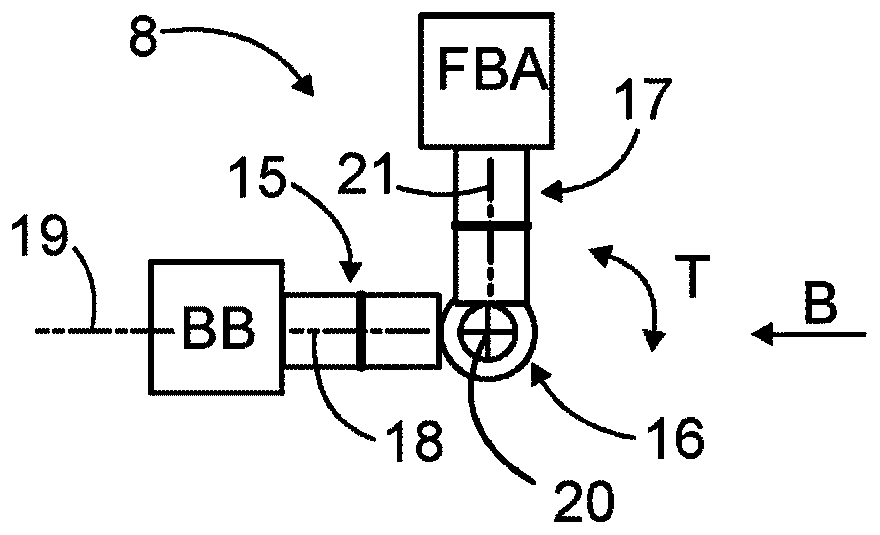

[0037] figure 1A rock drilling rig 1 for face drilling during tunneling is shown. The rock drilling rig 1 comprises a movable transport carrier 2 and one or more drilling booms 3 connected to the transport carrier 2 . When the drilling rig comprises a plurality of drilling booms, the drilling rig is often referred to as a drilling jumbo. The drilling boom 3 comprises a base boom part BB which is an elongated structure and whose first end BB1 is movably connected to a transport carrier. At the distal second end BB2 of the base cantilever portion is the feed beam assembly FBA. The feed beam assembly FBA may comprise a feed beam 5 and a rock drilling machine 6 supported on the feed beam 5 . The rock drilling machine 6 may comprise a shank at the front end of the rock drilling machine 6 for connecting the tool 7 . The feed beam assembly FBA is connected to the second end BB2 of the base boom section by means of a front joint arrangement 8 (may also be referred to as a wrist jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com