Conveyor belt type needle detector and sensitivity testing method thereof

A technology for sensitivity testing and conveyor belts, which is applied in the field of needle detectors, can solve problems such as noise interference, the influence of detection sensor detection sensitivity, and the inability of probes to complete detection work, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention. The components in the structures in the drawings of the embodiments are not scaled according to the normal scale, so they do not represent the actual relative sizes of the structures in the embodiments. The above or upper side of the structure or surface includes the case where there are other layers in the middle.

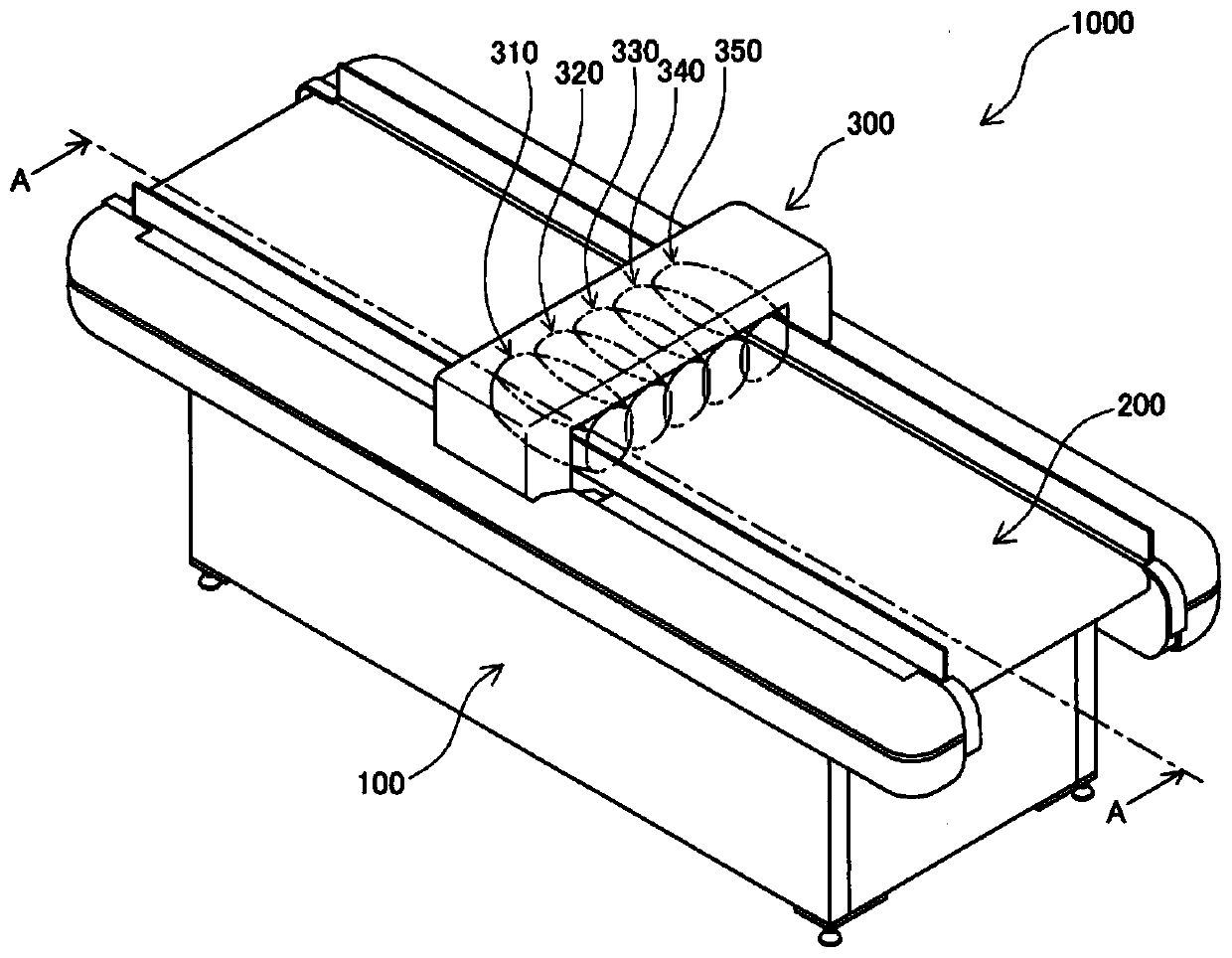

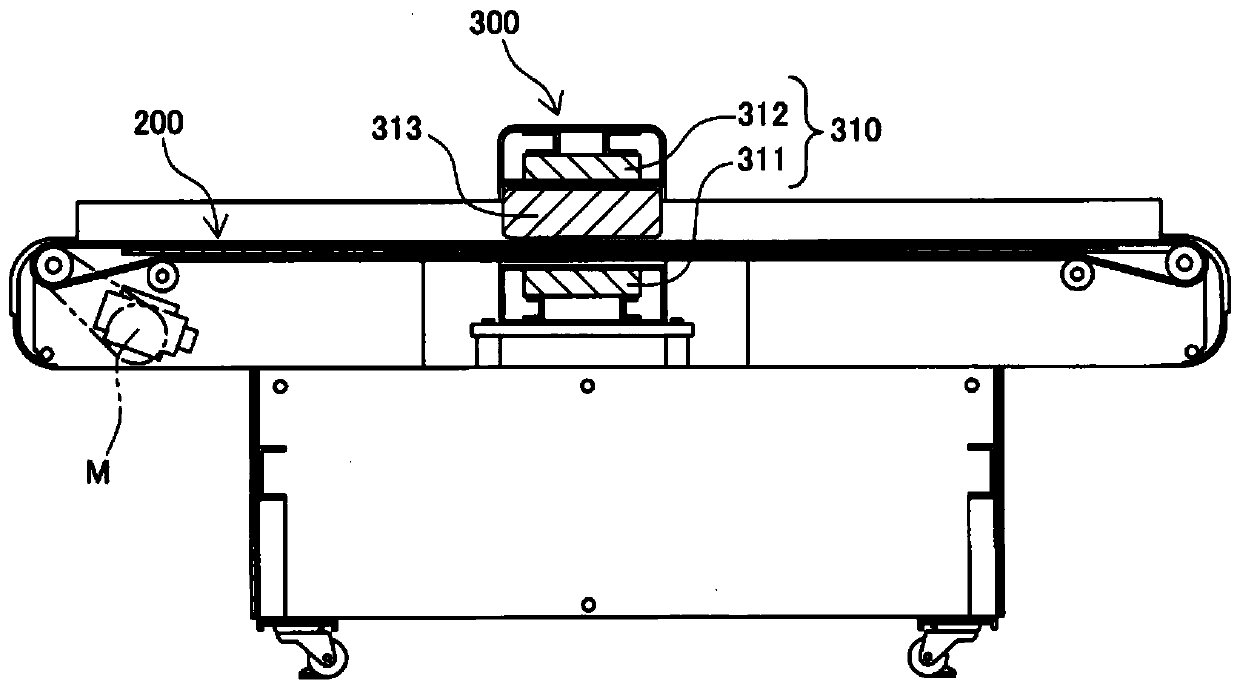

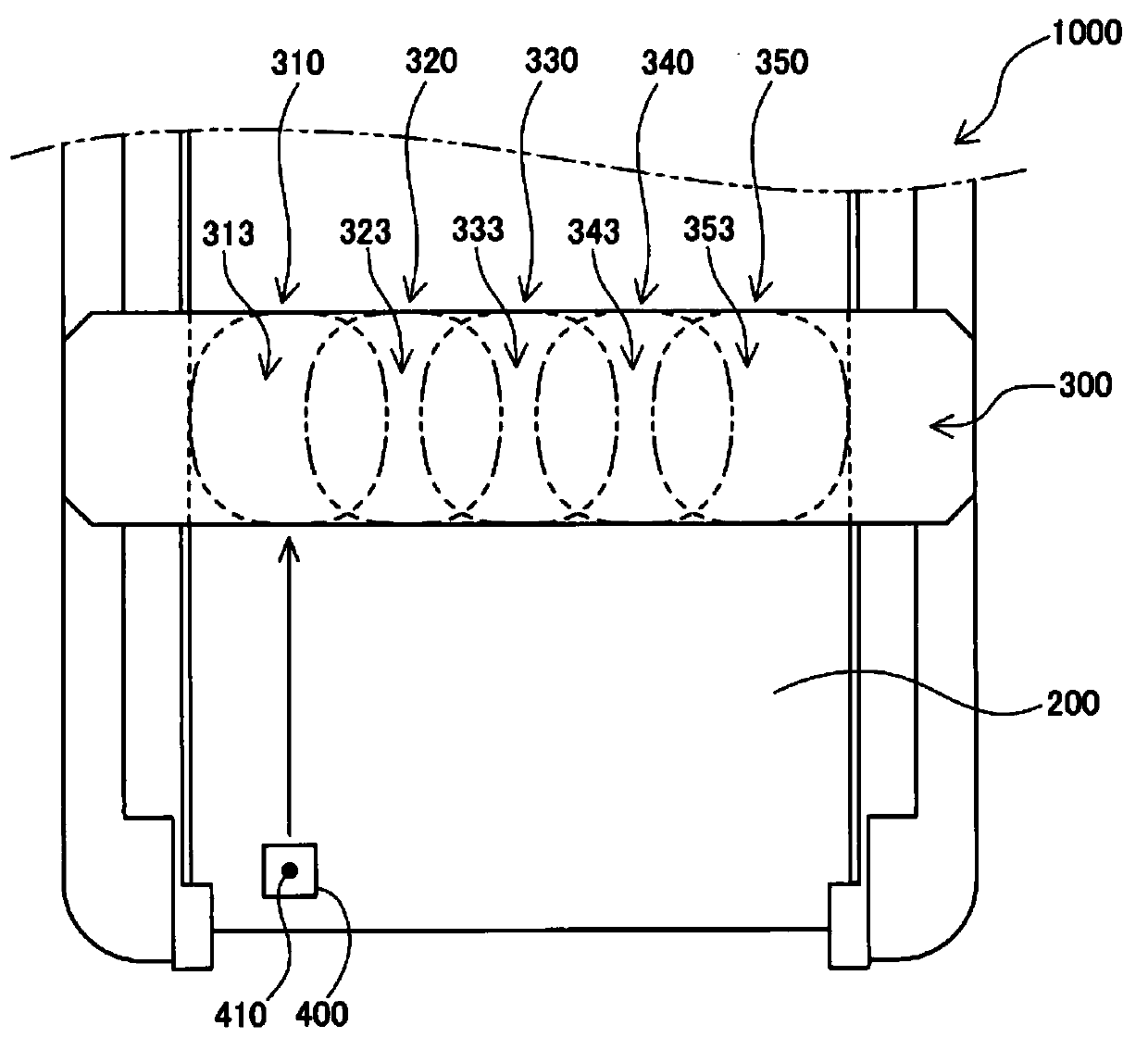

[0038] Figure 5 It is an enlarged view of the front end side of the top view of the conveyor belt type needle detector of the present invention; Image 6 It is a side view of the conveyor belt type needle detector of the present invention; Figure 7 It is an example diagram of the detection values of each detection sensor of the probe in the present invention; Figure 8 The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com