Three-bar oscillating mechanical arm for feeding and discharging glass

A three-link, swinging technology, applied in the directions of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of adjusting the swing arm of glass loading and unloading, low glass loading and unloading efficiency, and low accuracy of placement position, etc., to achieve stable operation. High, improve the conveying efficiency, the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

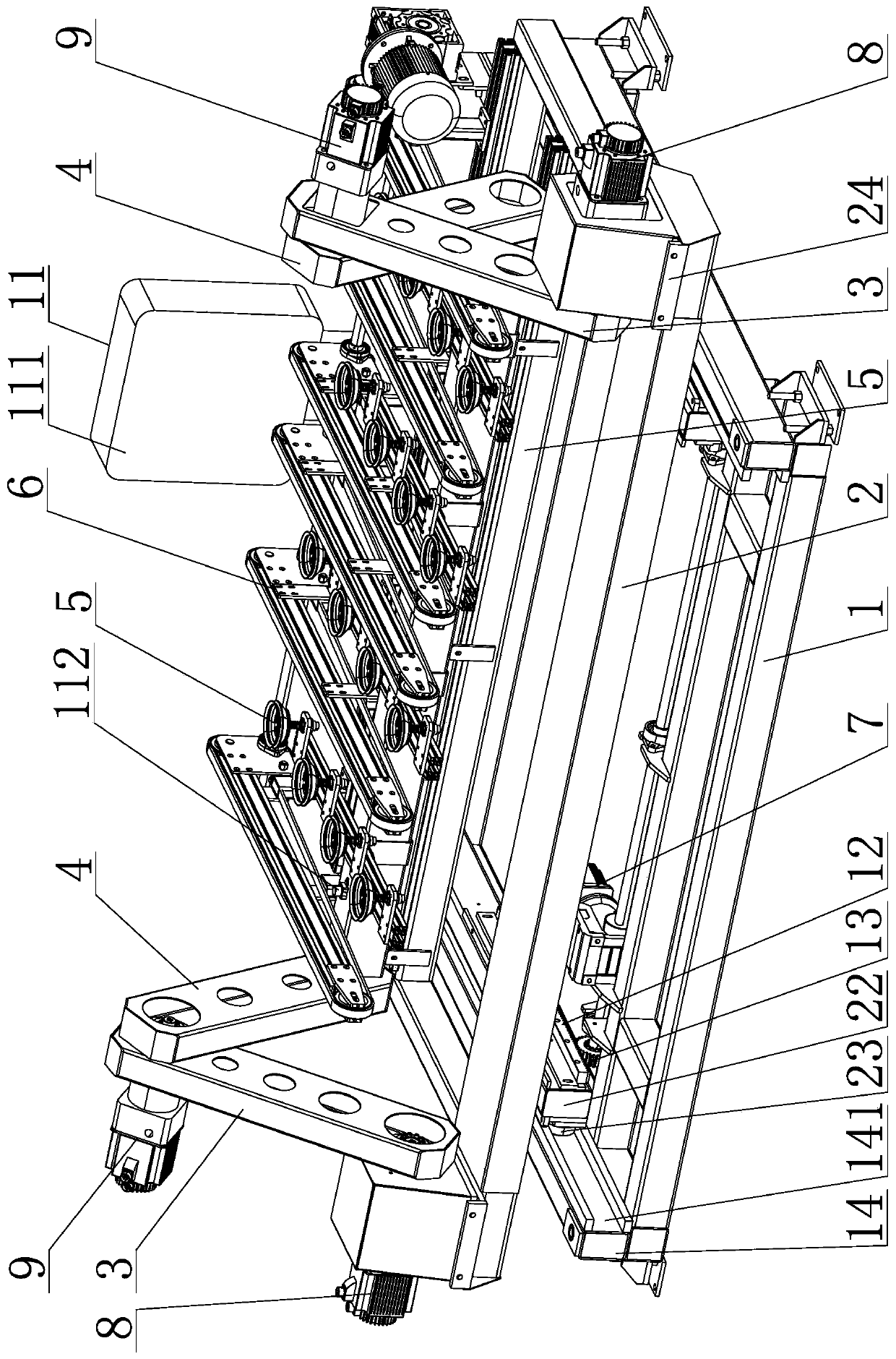

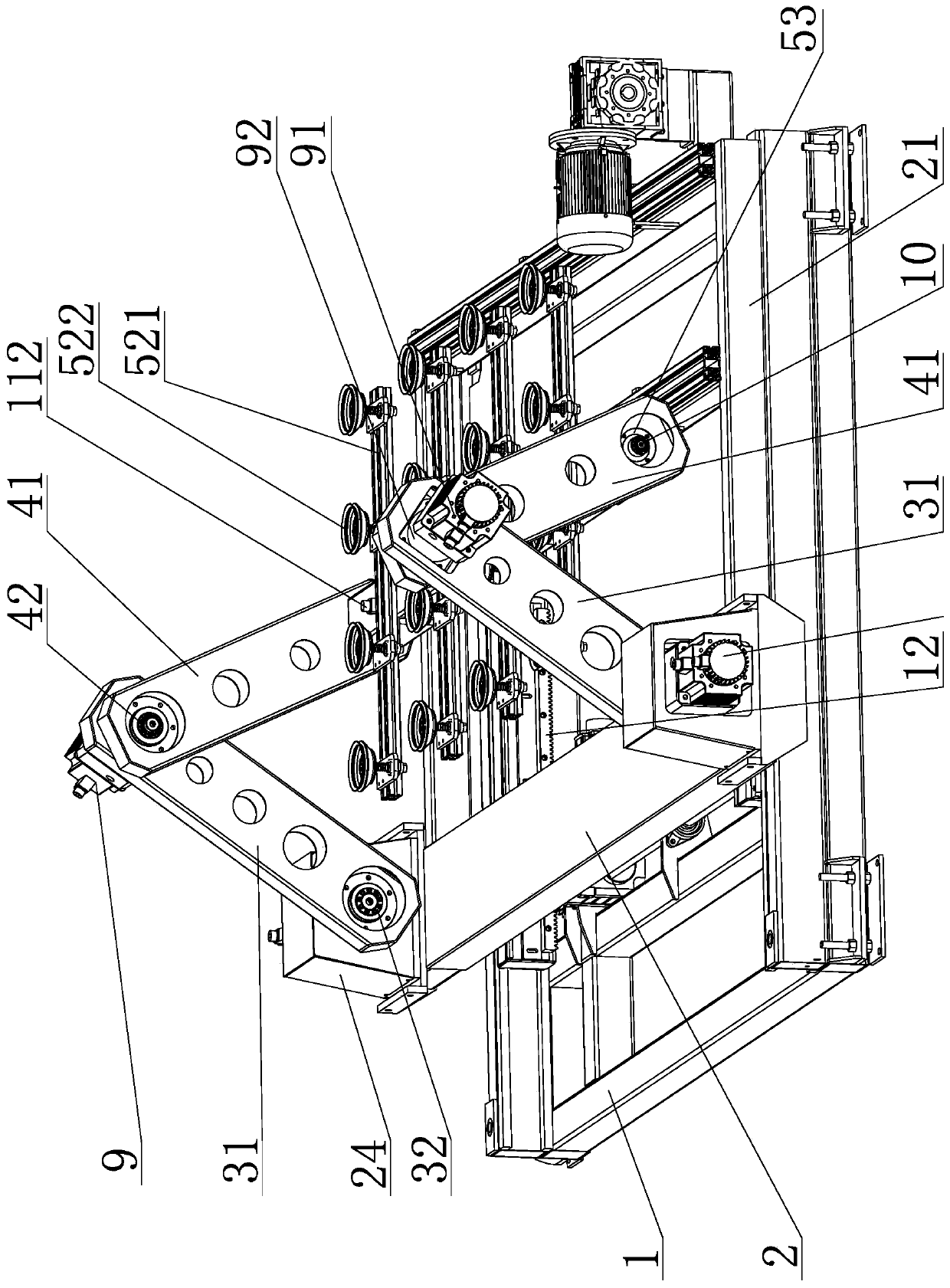

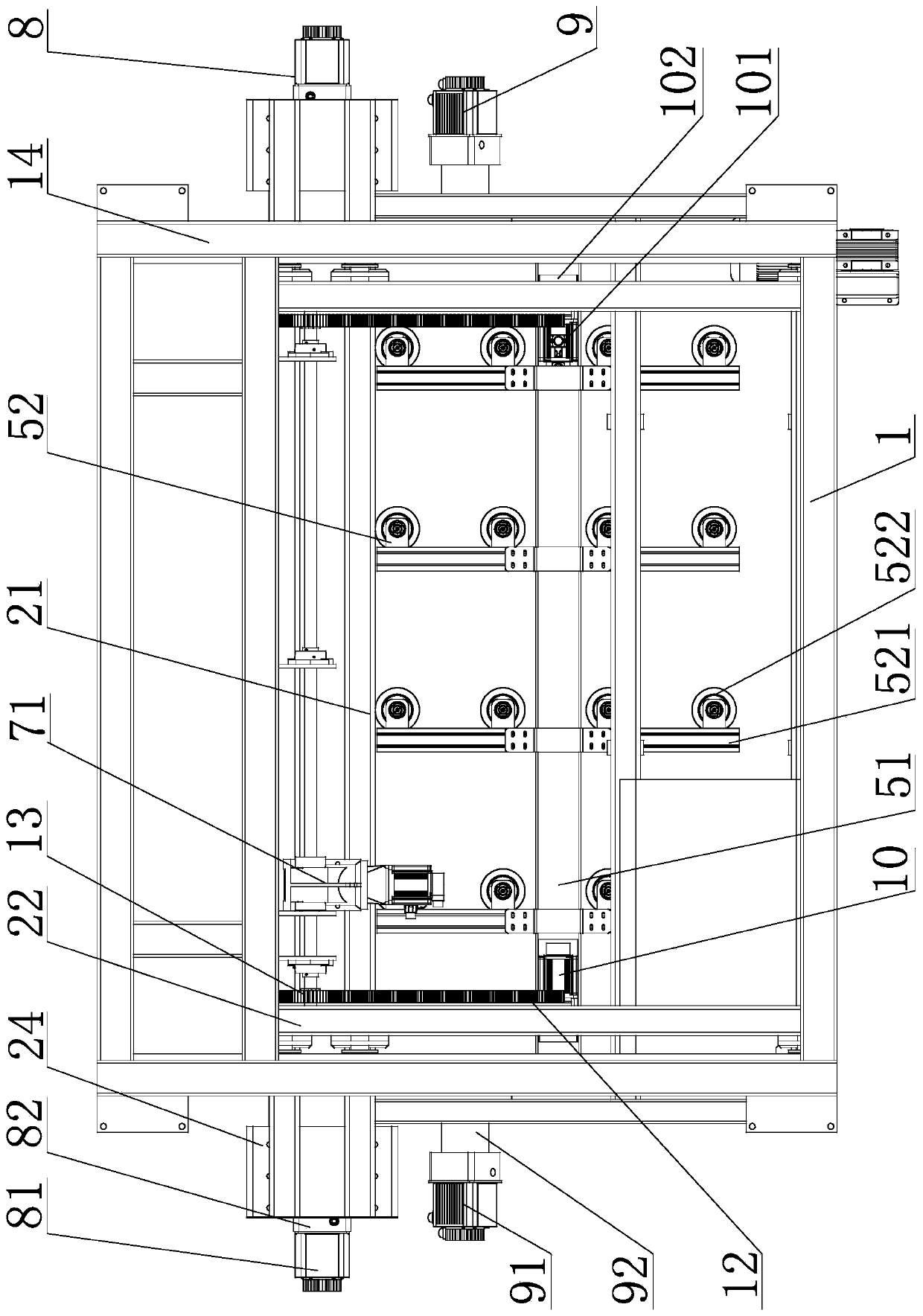

[0033] According to attached Figure 1 to Figure 4 As shown, the three-link swinging mechanical arm for loading and unloading glass of the present invention includes a fixed chassis 1, a movable assembly frame 2, a primary swing assembly 3, a secondary swing assembly 4, a rotary suction cup assembly 5, a glass Delivery platform 6. The glass conveying platform 6 is installed on the movable assembly frame 2 , and the movable assembly frame 2 is slidably connected to the fixed chassis 1 . The positioning end shaft of the first-level swing combination 3 is connected to the movable combination frame 2, the swing end shaft of the first-level swing combination 3 is connected to the positioning end of the second-level swing combination 4, and the swing end of the second-level swing combination 4 is connected to the rotary Suction cup combination 5-axis connection.

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com