Movable palletizing robot

A palletizing robot and mobile technology, applied in the field of robotics, can solve the problems of large volume and weight, single application occasion, high motor power, etc., and achieve the effect of simple structure, lightening the weight of the whole machine, and reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

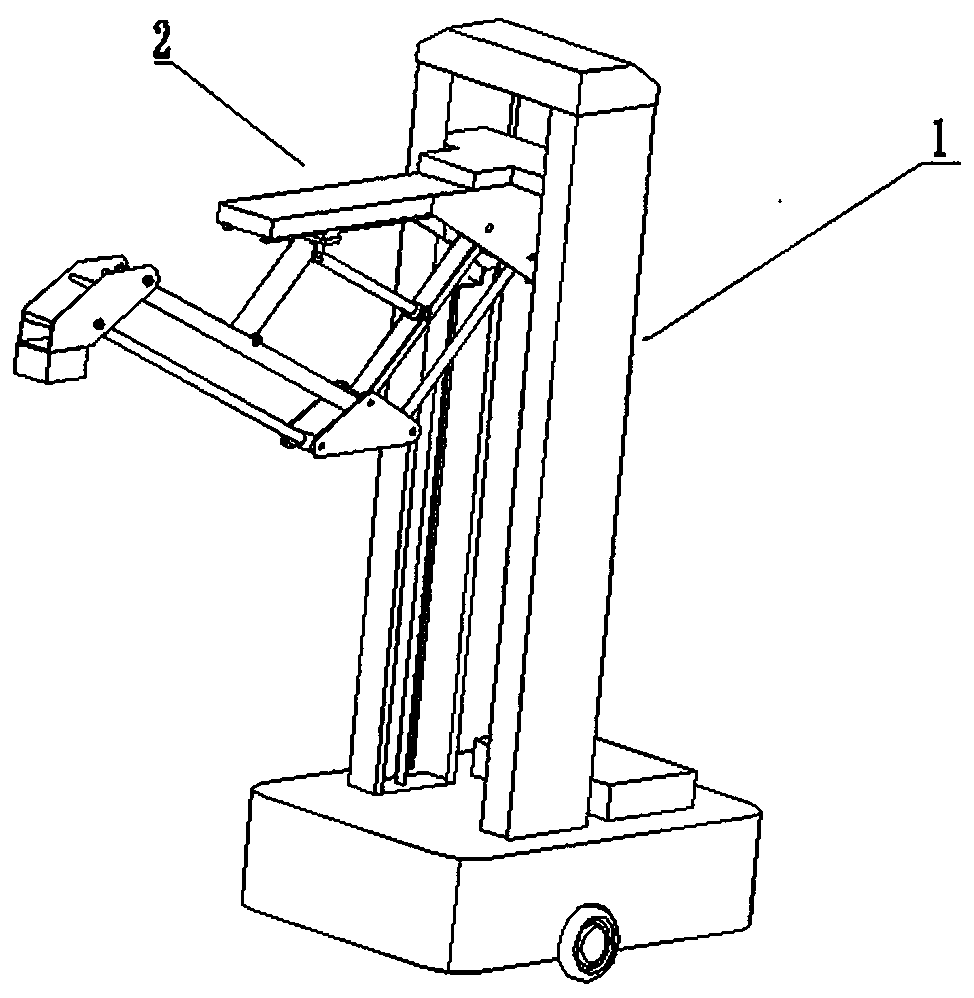

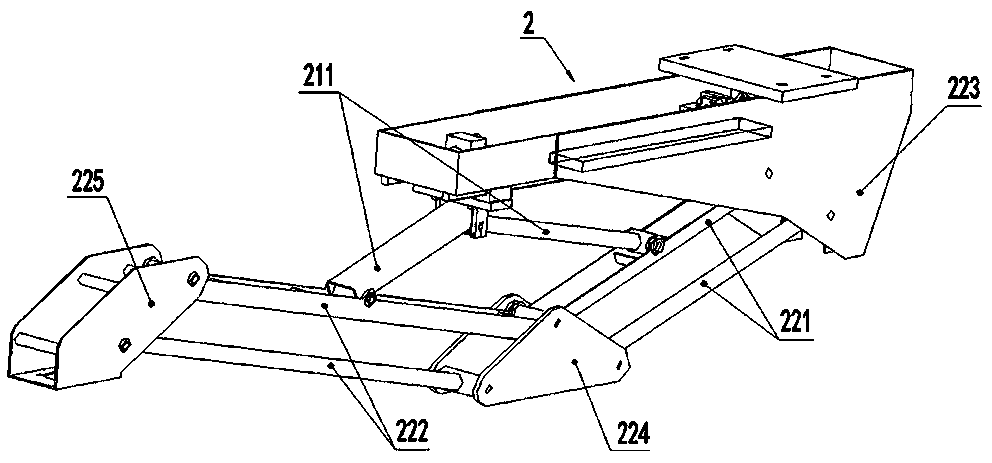

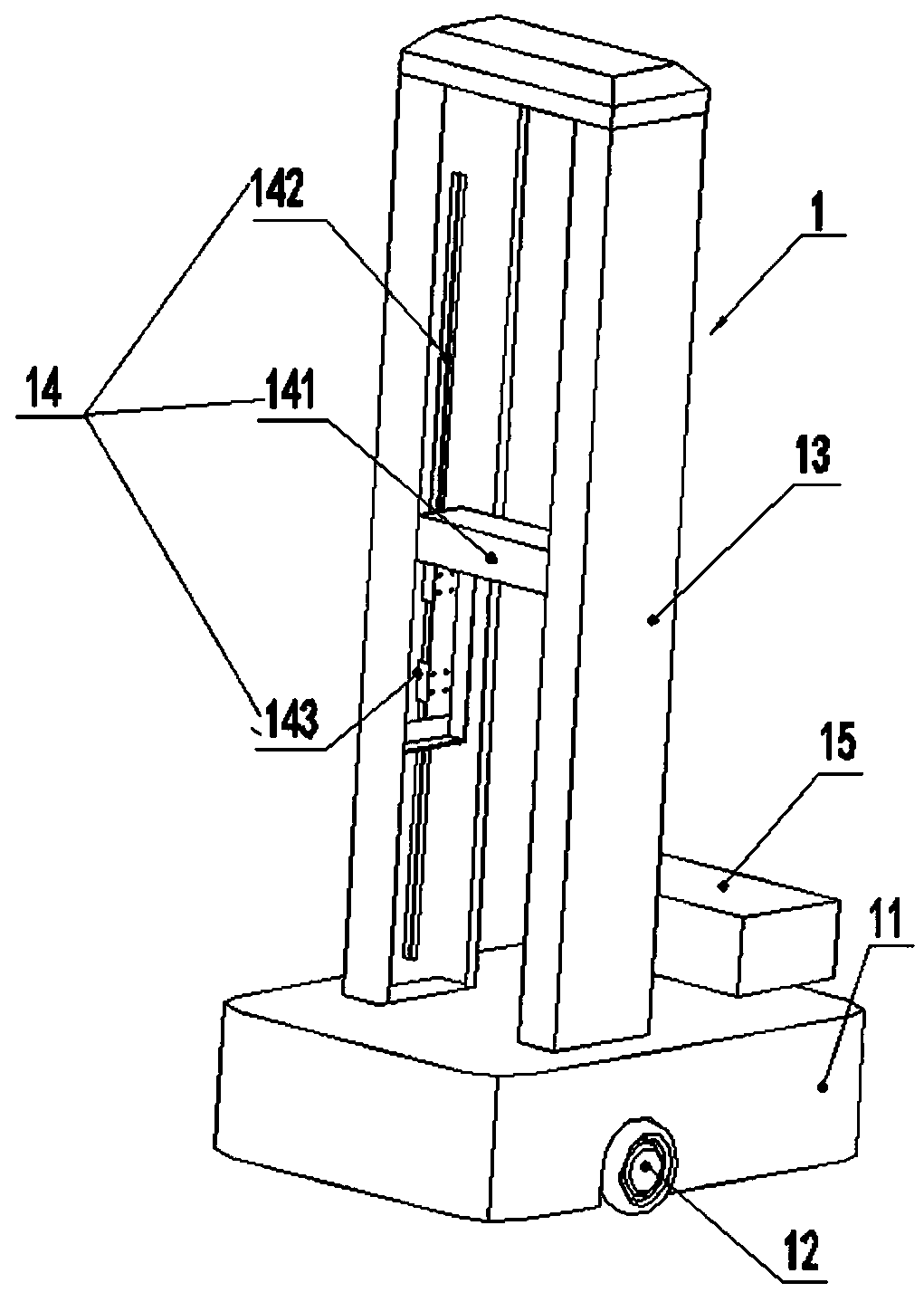

[0031] refer to figure 1 , which is a schematic structural diagram of a palletizing robot provided by an embodiment of the present invention. The palletizing robot in this embodiment is used to grab target goods, move to a designated location and stack them neatly. After the palletizing robot receives the position information of the target goods, it automatically navigates to the appropriate position of the corresponding target goods, and moves the lifting column 1 to adjust the height of the mechanism-type telescopic arm 2 in the vertical di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com