Easy-disassembled ultrasonic vibrator

An ultrasonic and easy-to-disassemble technology, applied in the field of easy-to-disassemble ultrasonic vibrators, can solve problems such as difficult disassembly of ultrasonic vibrators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

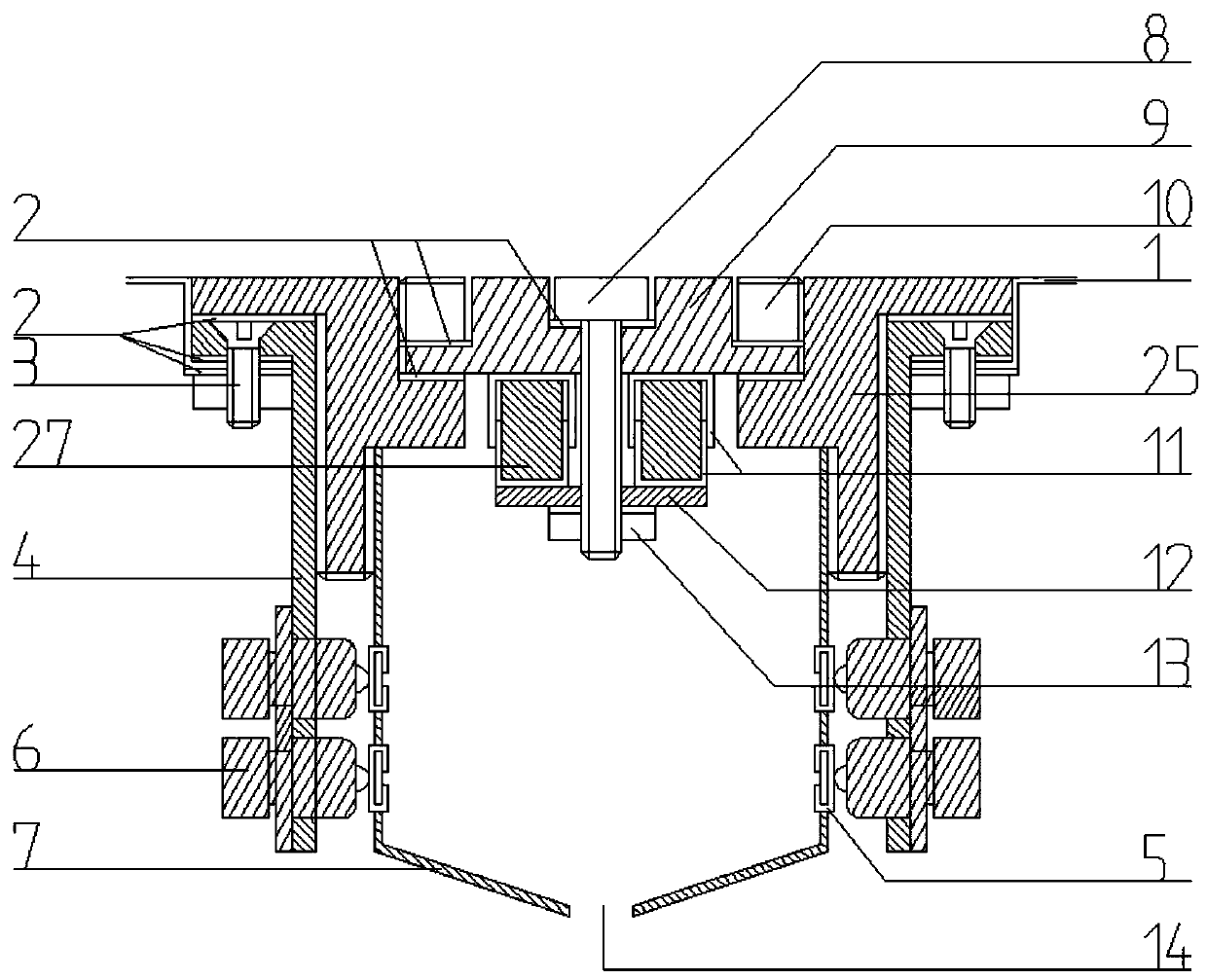

[0034] Such as figure 1 As shown, the easy-to-detach ultrasonic vibrator includes a vibrator mounting base 4 installed on the cleaning container wall 1. The vibrator mounting base 4 includes a mutually perpendicular mounting ring portion and a mounting barrel portion, and the mounting ring portion is located at the center of the mounting barrel portion. In the upper part, the installation ring part is connected with the cleaning container wall 1 through the first fixing screw 3 to realize the fixation of the vibrator mounting seat 4; the inner wall of the installation barrel part is provided with a first internal thread. The vibrator fixing seat 25 includes a fixed ring portion and a fixed barrel portion perpendicular to each other. The fixed ring portion is located on the upper part of the fixed barrel portion. The width and size of the fixed ring portion ensure that the installation ring portion can be covered, and the fixed ring portion There is a sealing shock-absorbing pa...

Embodiment 2

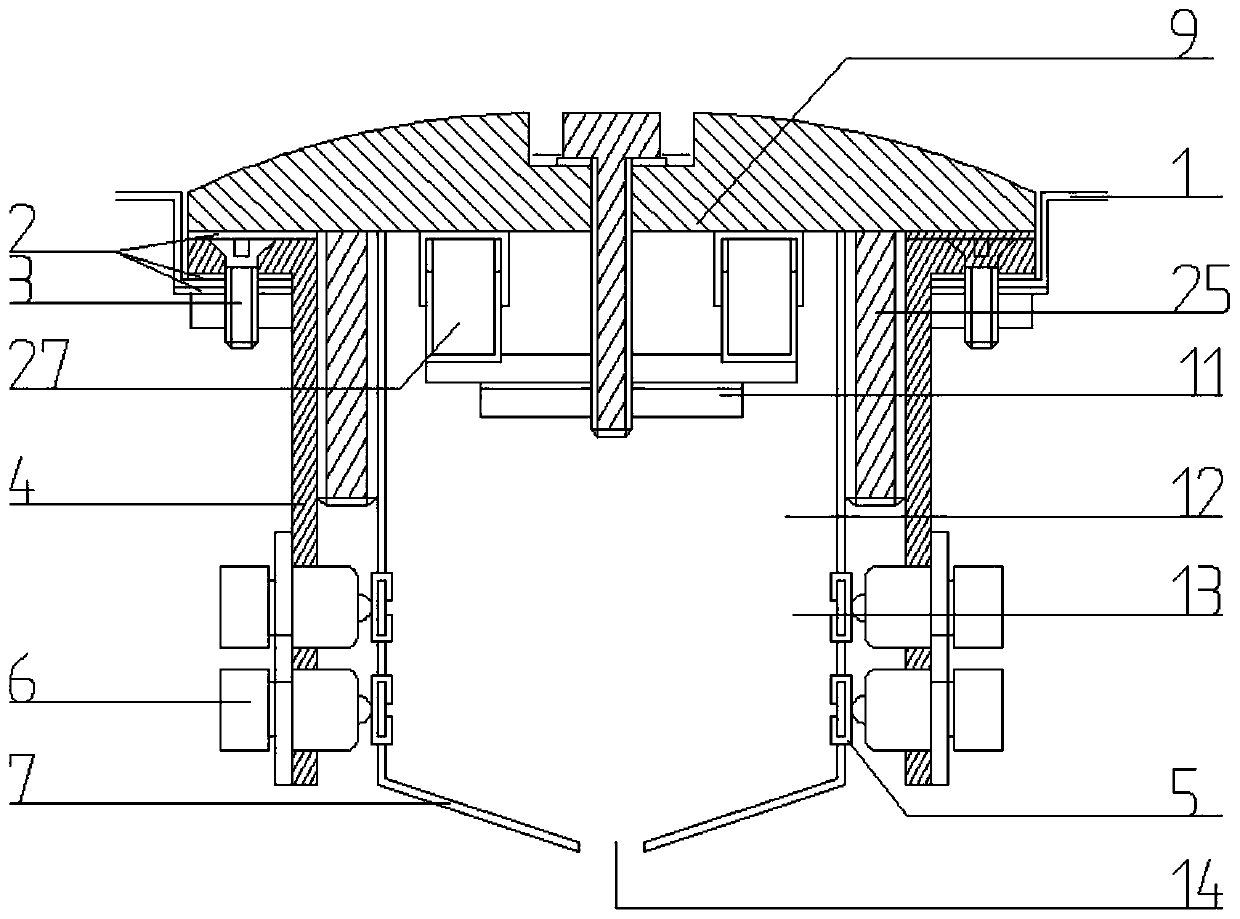

[0040] The difference between this solution and the first embodiment is that the radiating surface of the clamped iron on the vibrator is an arc-shaped radiating surface. Such as figure 2 As shown, the arc radiation surface has a wider radiation range than the plane radiation surface, and is suitable for larger spaces.

Embodiment 3

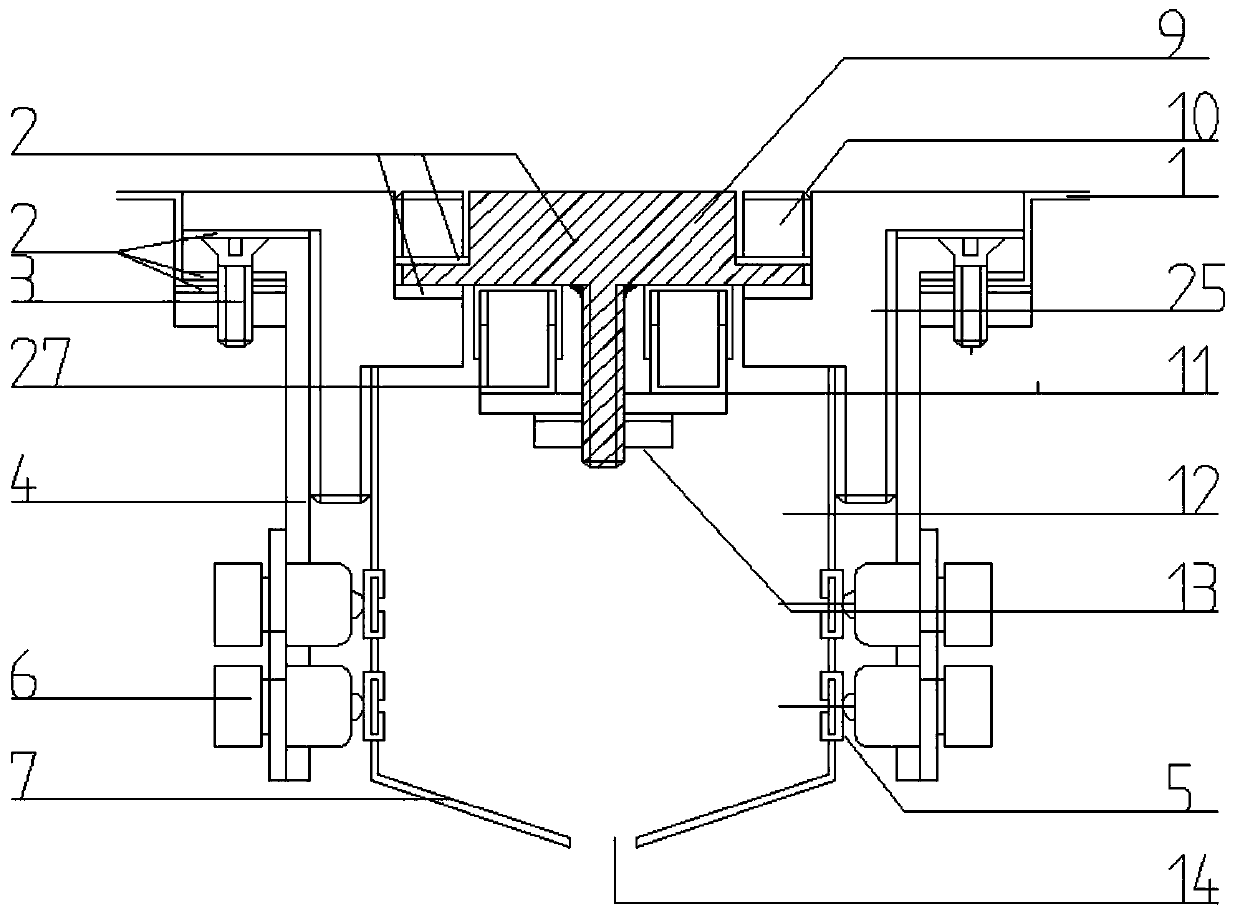

[0042] The difference between this solution and Embodiment 1 and Embodiment 2 is that: the top of the central screw is welded to the bottom of the clamp iron on the vibrator. Such as image 3 with Figure 4 As shown, compared with the first embodiment, the connection between the central screw of this solution and the clamping iron on the vibrator is tighter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com