Reel type hole precision seeding device

A sowing device and reel technology, which is applied in sowing, planter parts, agriculture, etc., can solve the problems of difficult to guarantee reliability, increase the requirement of installation accuracy, and early breakage, so as to ensure the reliability and stability of the equipment and reduce the The effect of high requirements for installation accuracy and lower requirements for installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Seed selection agency part:

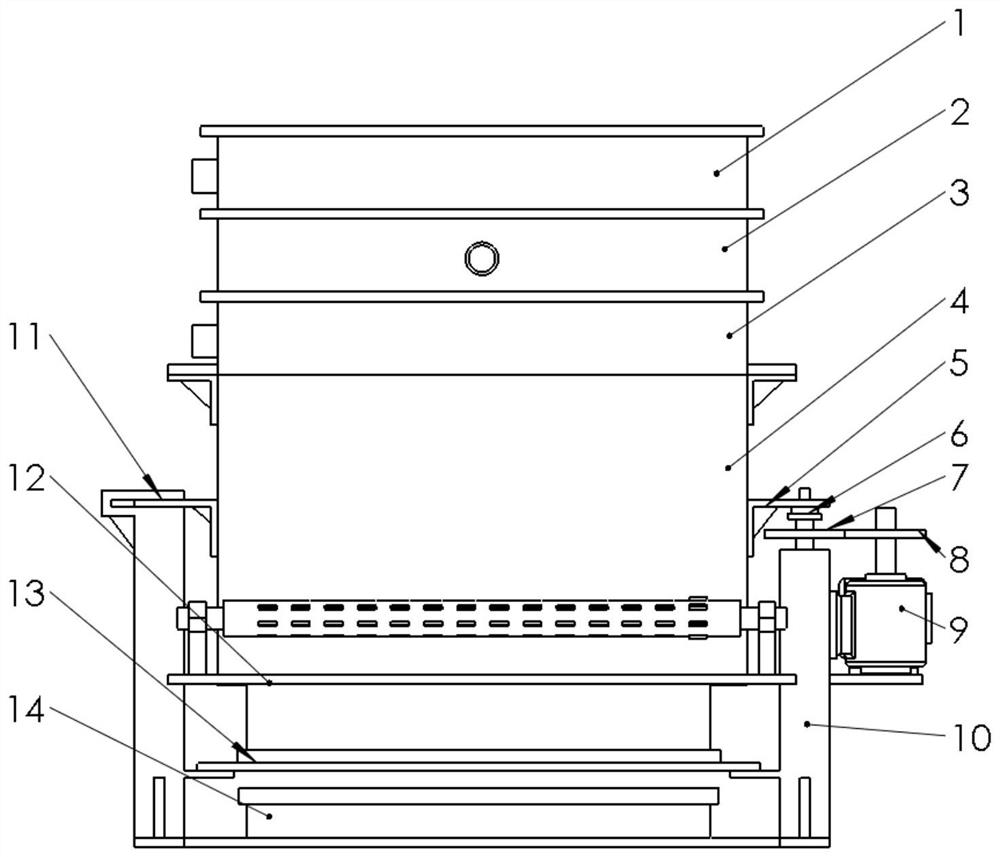

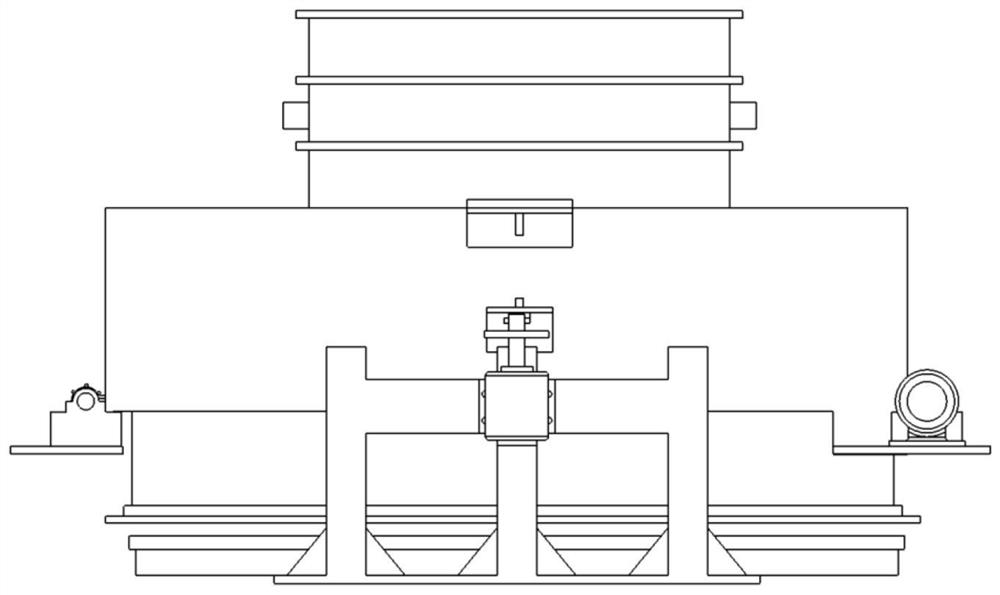

[0031] see Figure 1-5 , the third-level sorting box 3 is installed on the seed filling box 4; the second-level sorting box 3 is installed on the third-level sorting box 3; the first-level sorting box 1 is installed on the second-level sorting box 2;

[0032] Part of the filling mechanism:

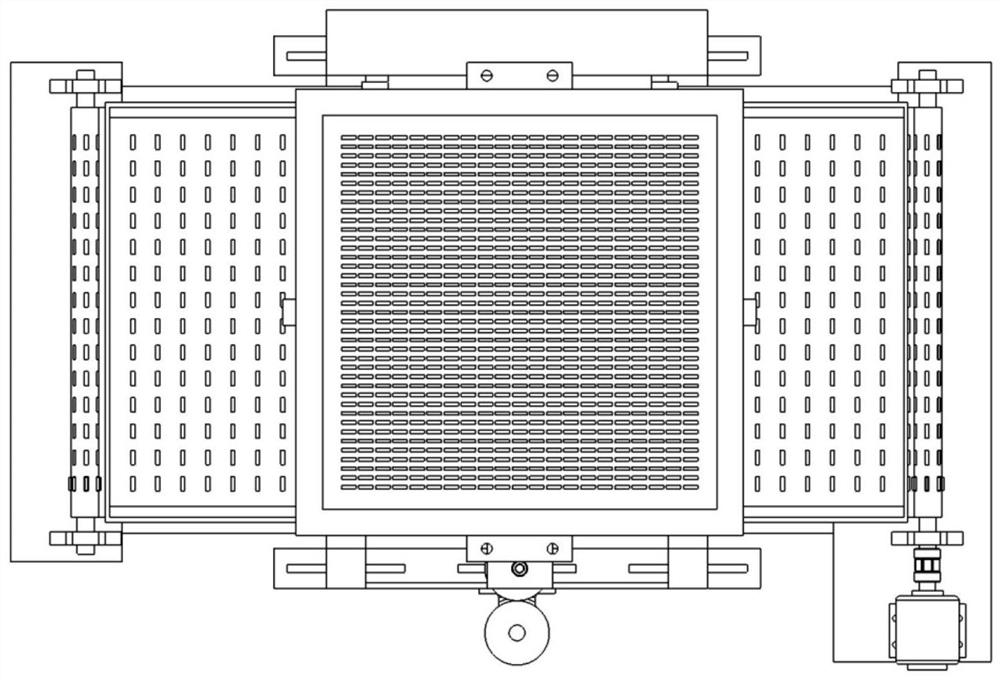

[0033] The driving motor 9 is installed on the frame 10; the gear one 8 is installed on the driving motor 9, the gear two 7 is installed on the eccentric support 6, and is concentric with the main shaft of the eccentric support 6, and the gear one 8 and the gear two 7 form a gear pair for driving Motor 9 transmits power to eccentric support 6; Eccentric support 6 is installed on the frame 10; Then, between the main shaft of the eccentric support 6 and the frame 10, the rotating motion is completed through the frame bearing 16; the support bearing 15 is fixedly connected with the support frame 5, and the rotation between the eccentric shaft of the ecce...

Embodiment 2

[0038] The difference from Embodiment 1 is: see Figure 7 , In the present embodiment, the seed drop platform is not provided, and the hole tray 14 is directly provided at the bottom of the seed filling box 4 . It is mainly aimed at low-density sowing seeds, such as vegetable seeds such as cucumber, tomato, and pepper, etc., without setting up a seed drop frame and a seed drop platform. Abandoning the seed drop table and drop frame structure, saving materials and reducing the difficulty of installation; the distance between the hole plate and the bottom plate is relatively close, reducing the uncontrolled travel of seeds, and avoiding the seeds due to the initial velocity and the free fall distance being too long And fly out of the hole range; after shortening the distance between the hole plate and the lower bottom plate, the overall structure is more compact.

[0039] All the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com