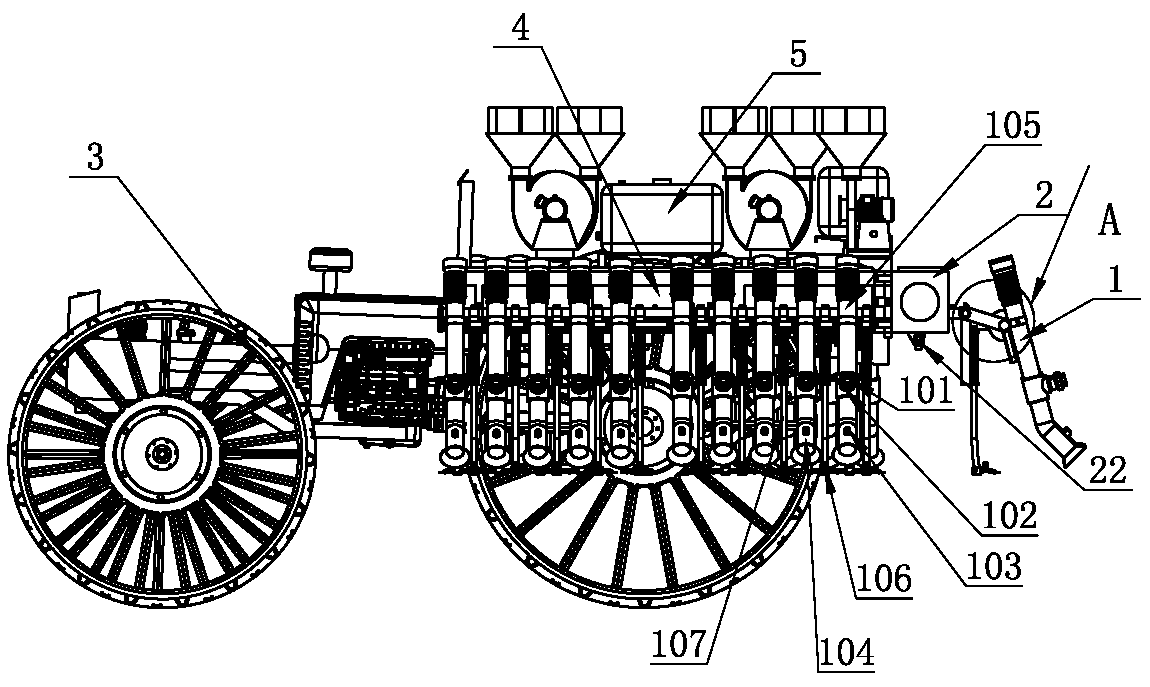

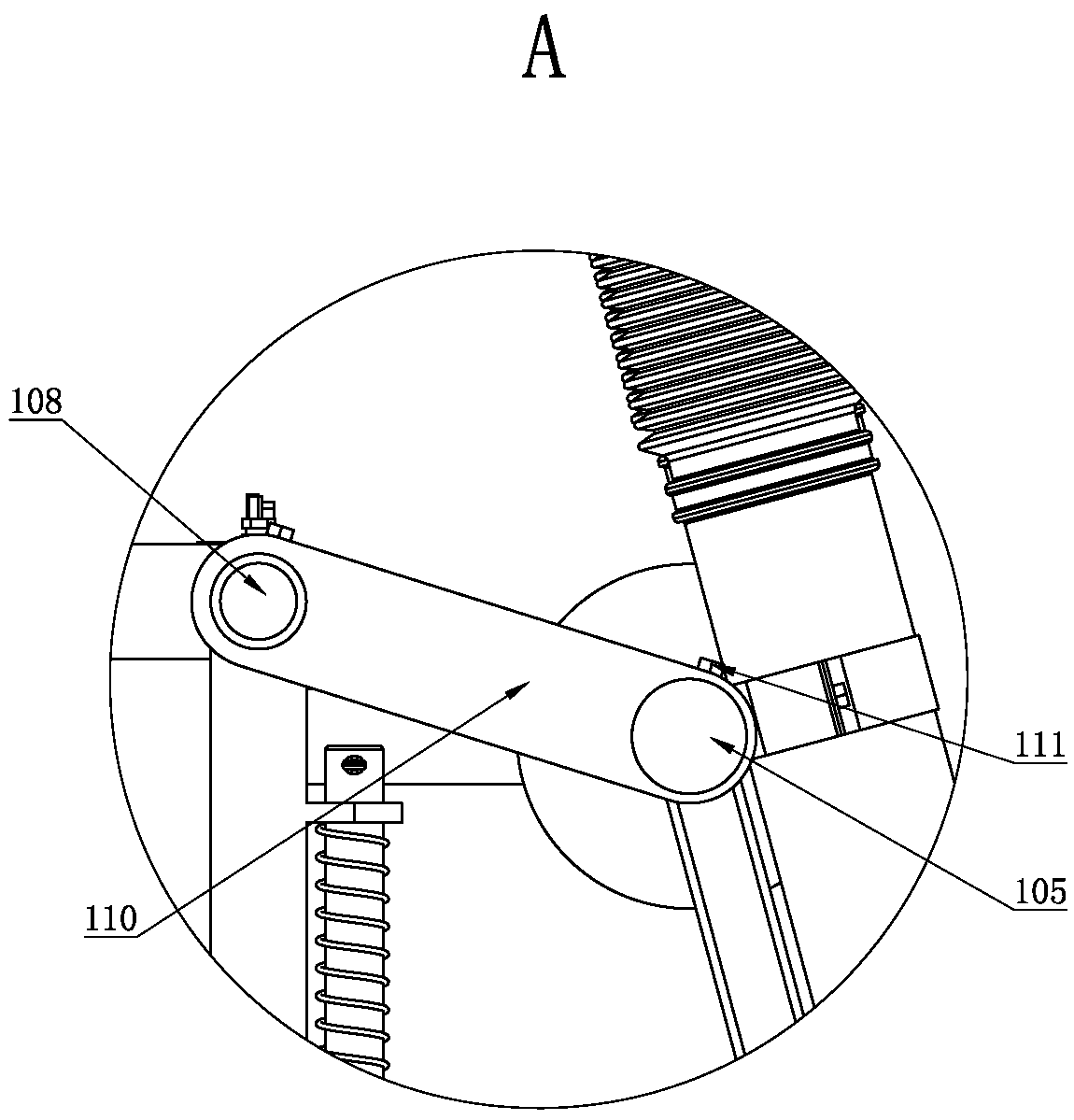

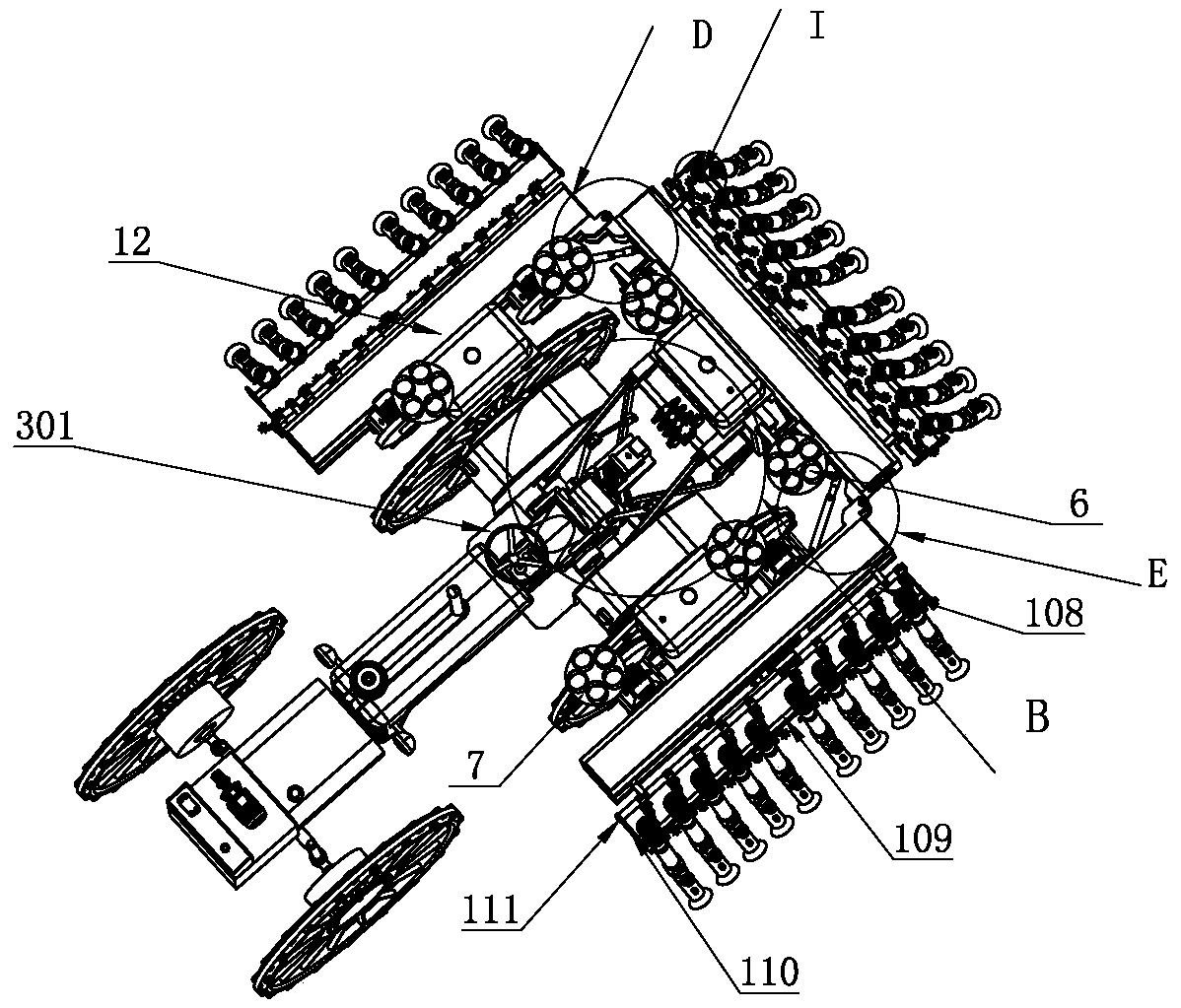

Fertilizer and pesticide application vehicle with mechanical weeding function

A mechanical weeding and functional technology, applied in the field of agricultural machinery, can solve problems such as poor adaptability, low efficiency, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] like Figure 17 A fertilizing and applicating vehicle with a mechanical weeding function is shown. The difference between this embodiment and Embodiment 1 is that the restricting member 106i is a one-way bearing 106i'. Viewed from the back to the front, the one-way bearing 106i at the right end is ', so that the grass scraping wheel 106e can only rotate clockwise, and the one-way bearing 106i' on the left end makes the grass scraping wheel 106e only rotate counterclockwise, and the clockwise and counterclockwise rotation directions are from top to bottom. direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com