Boiler combustion optimization system, method and device based on data driving and intelligent algorithm

A technology of boiler combustion and intelligent algorithm, which is applied in the combustion method, combustion regulation, and control of combustion, etc., can solve problems such as difficult operation of boilers, and achieve the effect of improving efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

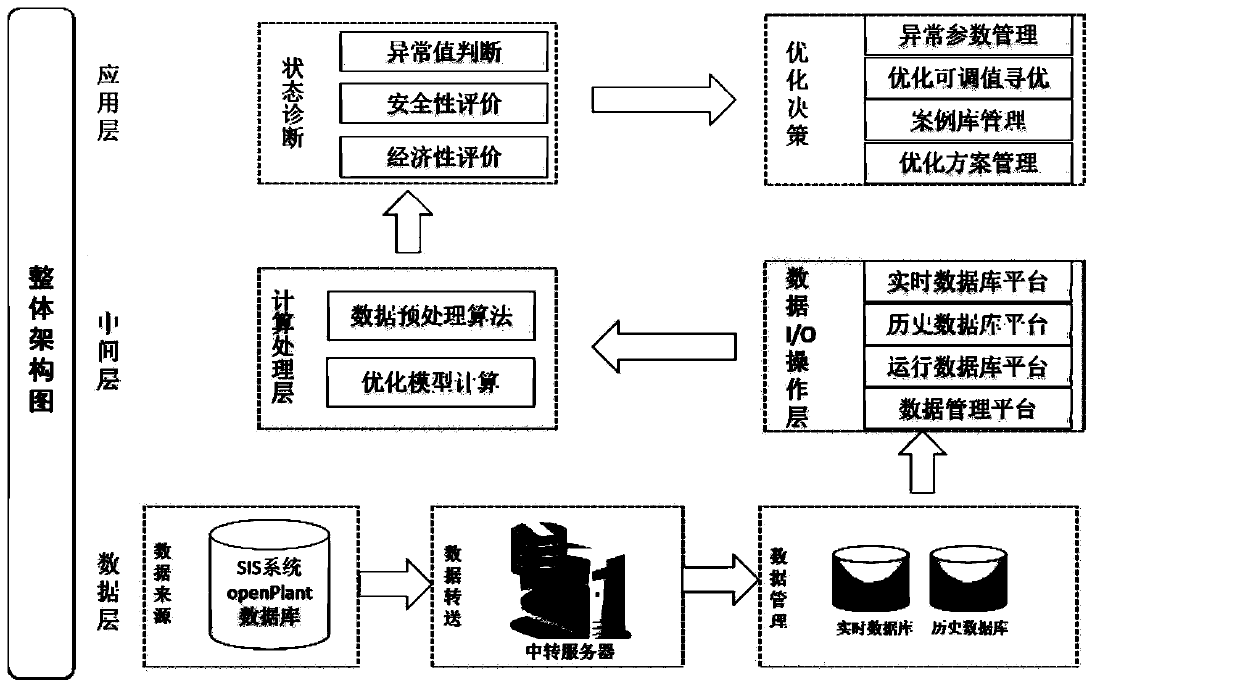

[0038] figure 1 It is a framework diagram of a boiler combustion optimization system according to an embodiment of this patent. As shown in the figure, the framework includes a data layer, an intermediate layer and an application layer.

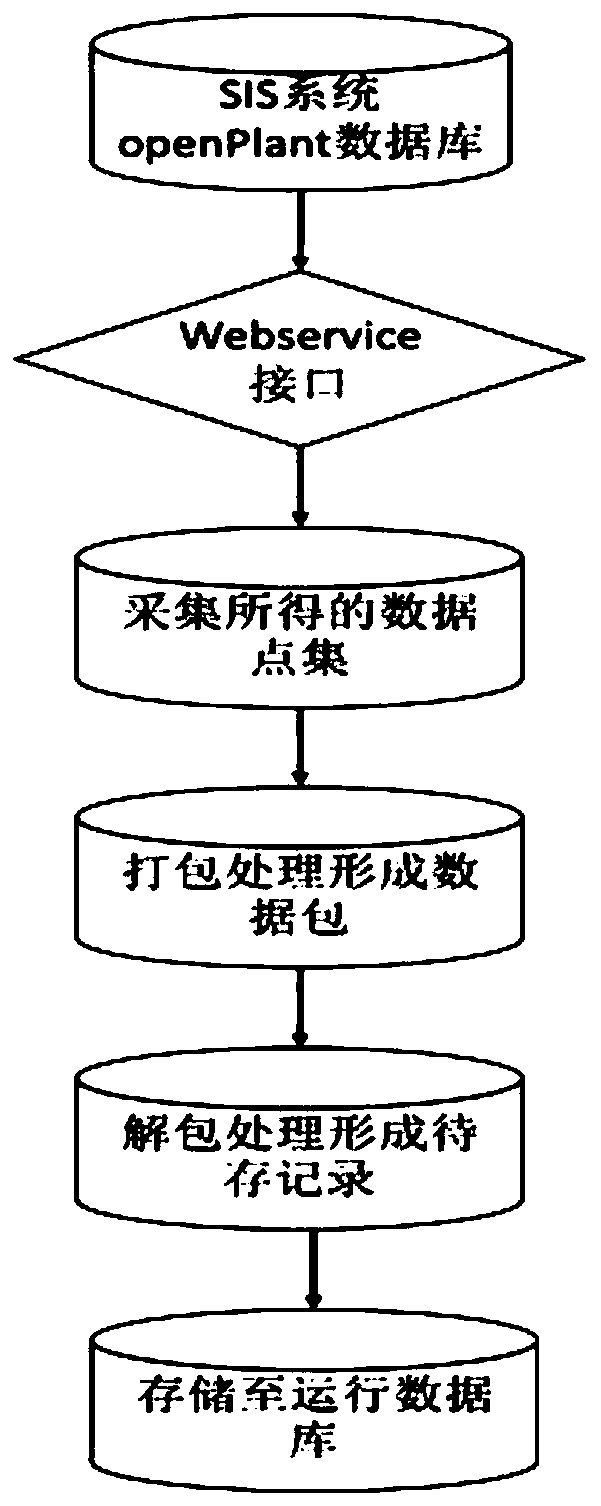

[0039] Wherein, the data layer implements data collection, data transmission and data management. Collect the running data required by the system from the SIS system, and manage the collected data. The data collected from the SIS system is through the WebService interface of the OpenPlant database of the SIS system, and the OPAPI is used to collect real-time data at a set frequency from the OpenPlant database of the SIS system. After the switch, the transfer server receives the real-time data collected, and the real-time The data is screened and filtered to select the required data and transmitted to the data management system of the core server, and the data is output to the middle layer.

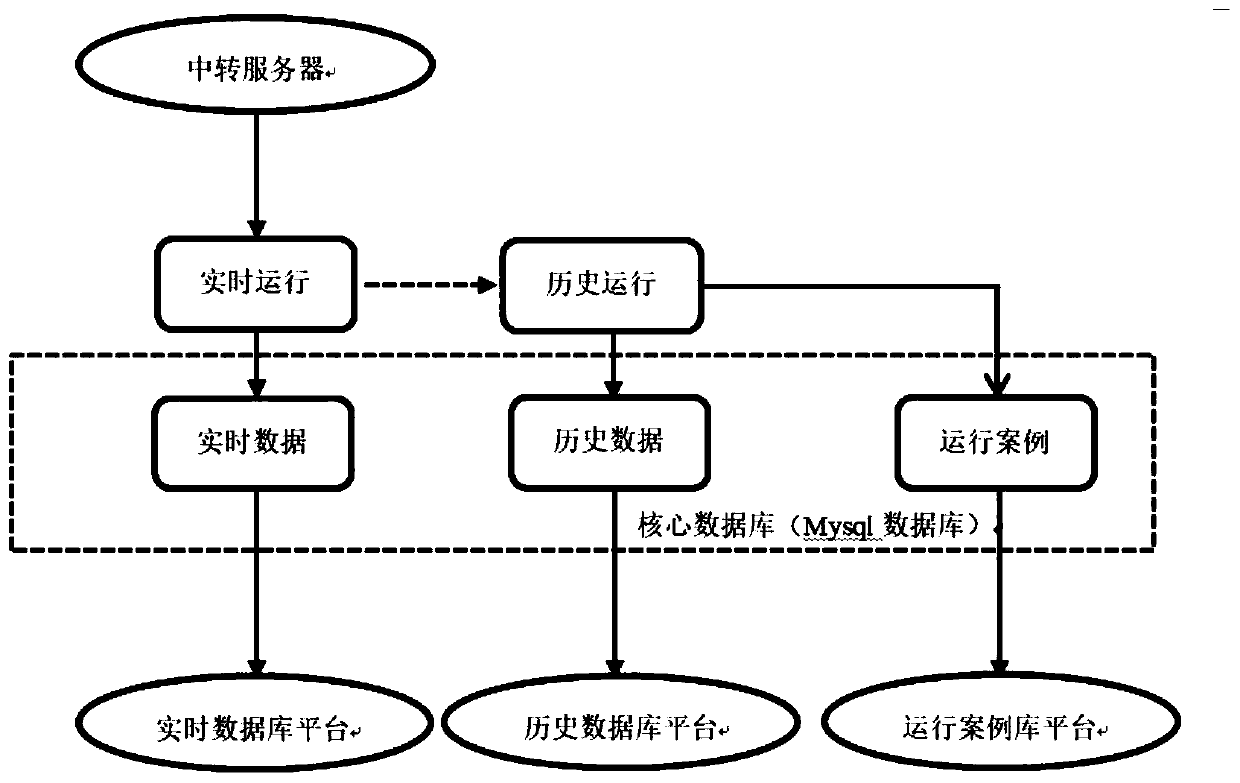

[0040] The data management system includes a core...

Embodiment 2

[0066] Figure 5 It is a flowchart of a boiler combustion optimization method according to an embodiment of this patent. As shown in the figure, the optimization method includes the following steps.

[0067] Data cleaning: filter out incomplete data segments in historical data; adopt scientific data preprocessing methods to eliminate "dirty data" in the field, and obtain representative high-quality data in operation.

[0068] Establishment of stable database: Judging the complete operation records, the operation records that meet the stability requirements are regarded as stable records, and their IDs are recorded.

[0069] Division of working conditions: According to different loads, coal quality, ambient temperature, etc., the steady-state operation records in the library are divided into different working conditions.

[0070] Construction of case base: through comparative analysis of a large amount of historical data, a collection of optimal operating conditions of boilers...

Embodiment 3

[0076] Figure 6 It is a schematic diagram of a boiler combustion optimization device according to an embodiment of this patent. As shown in the figure, the optimization device includes a data management module, an optimization module and a display module.

[0077] Among them, the data management module is used for data collection, transmission, storage and so on. Collect and temporarily store real-time data, store historical operation data, store optimization calculation result data, and transmit real-time data to the optimization module, and transmit optimization instructions to the display module.

[0078] Among them, the optimization module is used to receive the real-time data sent by the data management module, obtain optimization instructions through intelligent algorithm calculation and case library optimization, and transmit the optimization instructions to the data management module.

[0079] Among them, the display module is used to display the real-time data of bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com