Equilateral three-limb combination column structure of ultra-high performance concrete sleeves and construction method of equilateral three-limb combination column structure

An ultra-high-performance concrete column technology, which is applied to bridge parts, erection/assembly bridges, bridge materials, etc., can solve the problems of low early strength, fragility, and weak rigidity, so as to improve the strength of the section, reasonable structural design, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to explain the present invention more clearly, the present invention will be further described below in conjunction with the drawings and embodiments. Obviously, the drawings listed below are only some specific embodiments of the present invention.

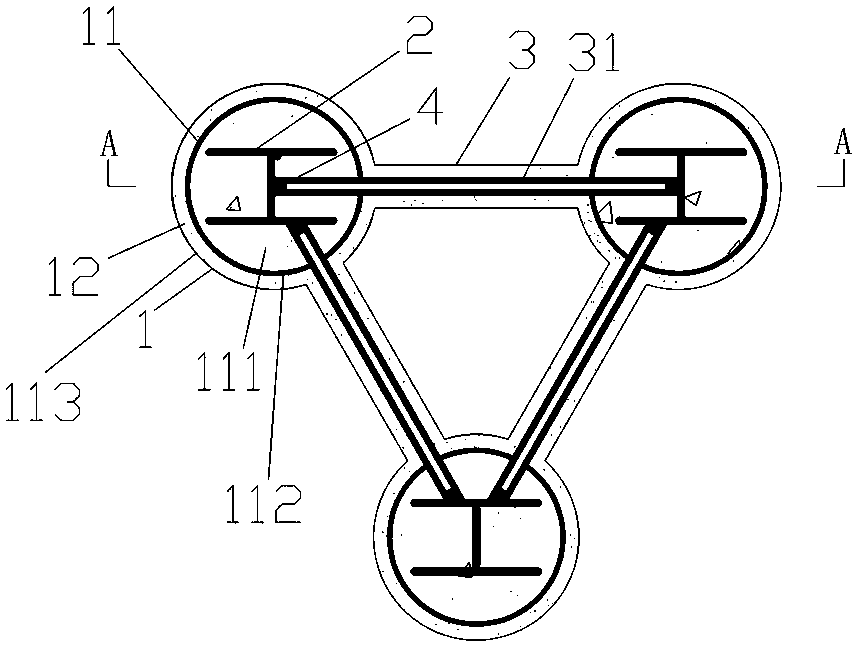

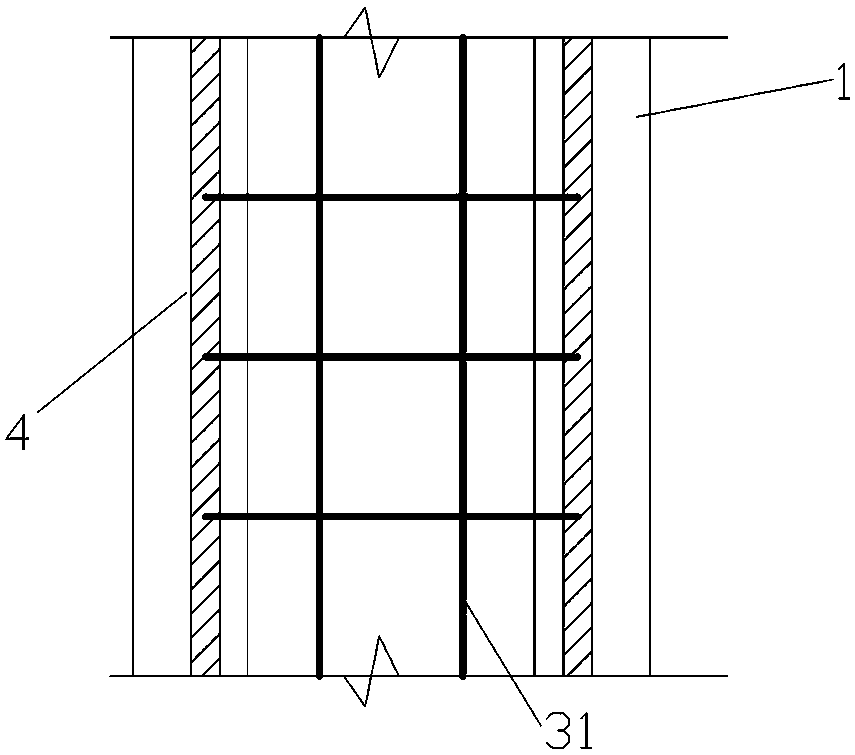

[0023] Such as Figure 1~2 As shown, an equilateral three-leg composite column structure of ultra-high performance concrete sleeve in the present invention includes three column limbs 1 distributed in an equilateral triangle and a reinforced ultra-high performance concrete column connected between any two column limbs 1 plate 3, the column limb 1 includes a concrete column 11 and an ultra-high performance concrete sleeve 12 sleeved on the outer periphery of the concrete column 11, the concrete column 11 includes H-shaped steel 2 and column concrete 111, and the column concrete 111 is The ultra-high-performance concrete sleeve 12 is formwork poured on the outside of the H-shaped steel 2; the reinforced ultra-high-pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com