Method for recycling waste steel by utilizing intelligent waste steel recycling device

A technology of recycling device and collection device, applied in conveyor control device, loading/unloading, transportation and packaging, etc., can solve the problems of large number of participants, high labor input cost, long time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

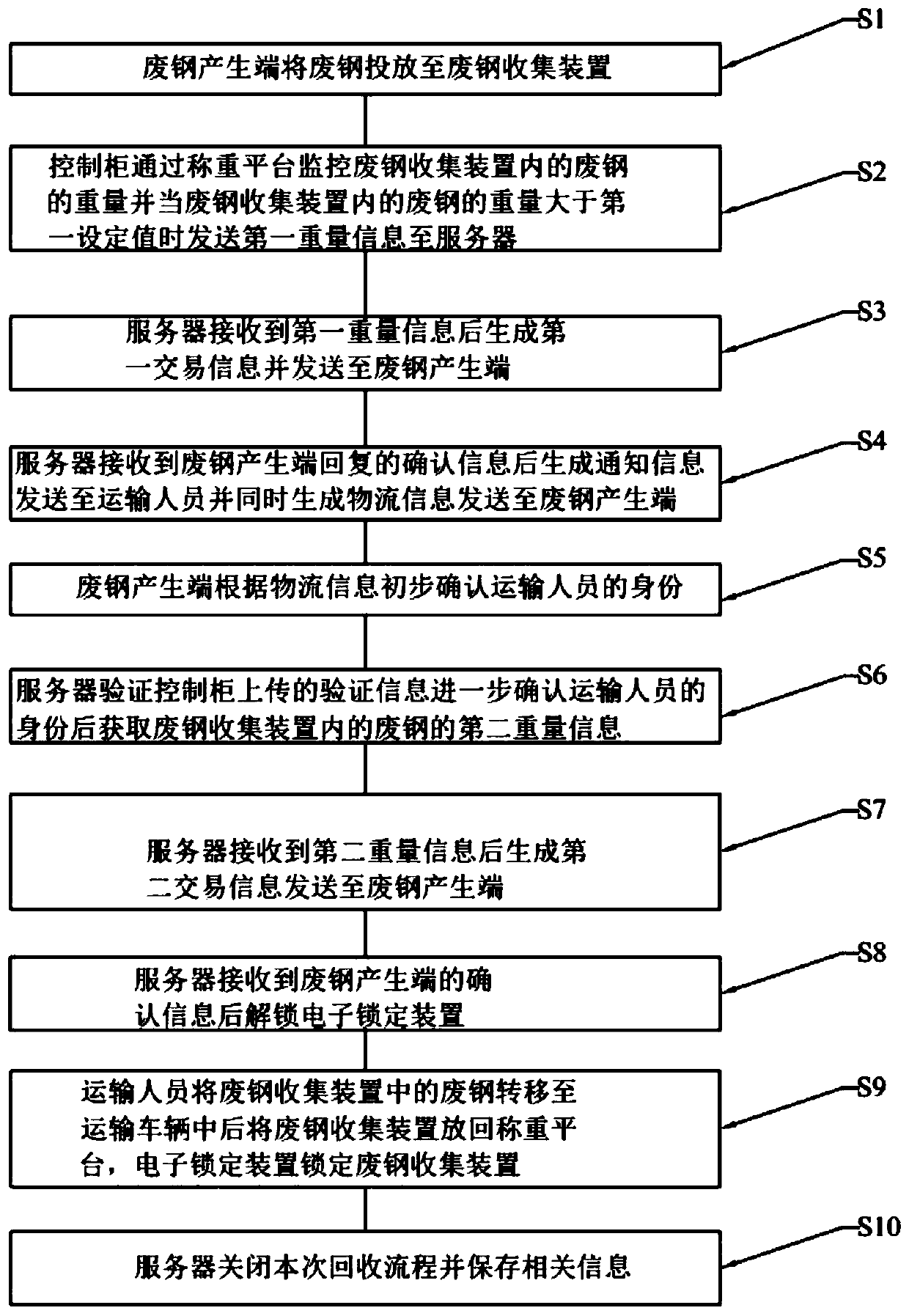

[0027] Such as figure 1 As shown, the present invention discloses a method for recycling steel scrap using an intelligent steel scrap recycling device, which is used in the intelligent scrap steel recycling device. The intelligent scrap steel recycling device mainly includes: a scrap steel collecting device, a weighing platform, an electronic locking device and a control cabinet. Wherein, the scrap steel collection device is used to hold scrap steel, the weighing platform is used to support the scrap steel collection device and collect the weight of scrap steel in the scrap steel collection device in real time, and the electronic locking device is used to lock the scrap steel collection device to The weighing platform, which is installed on the weighing platform, cooperates with the limiting part arranged on the scrap steel collection dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com