Packing box forming machine

A molding machine and packaging box technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of the appearance of the packaging box, the appearance of convex marks, and the reduction of the packaging quality of the packaging box, so as to increase the usability and aesthetics. , Reduce convex marks, enhance the effect of usability and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

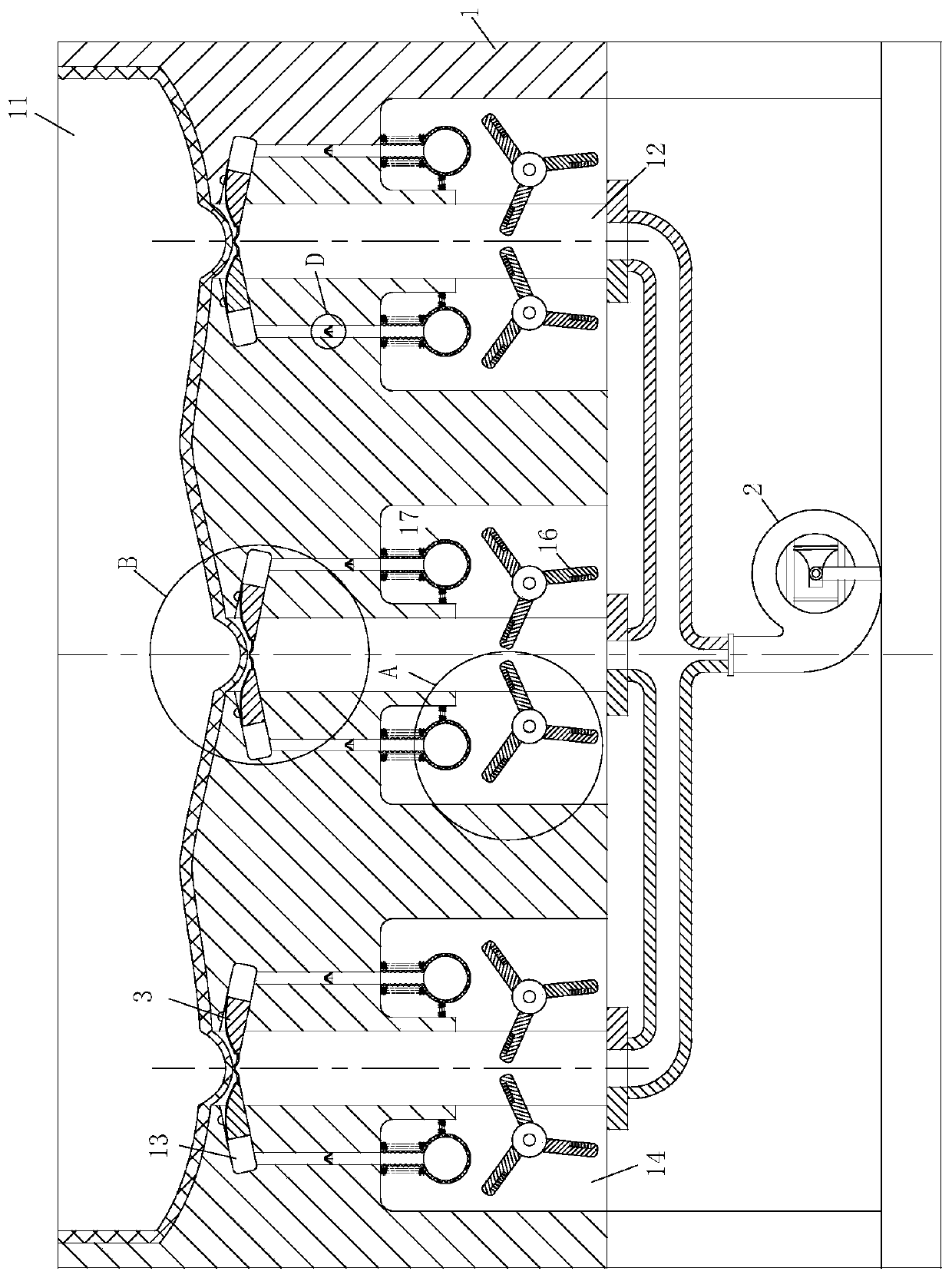

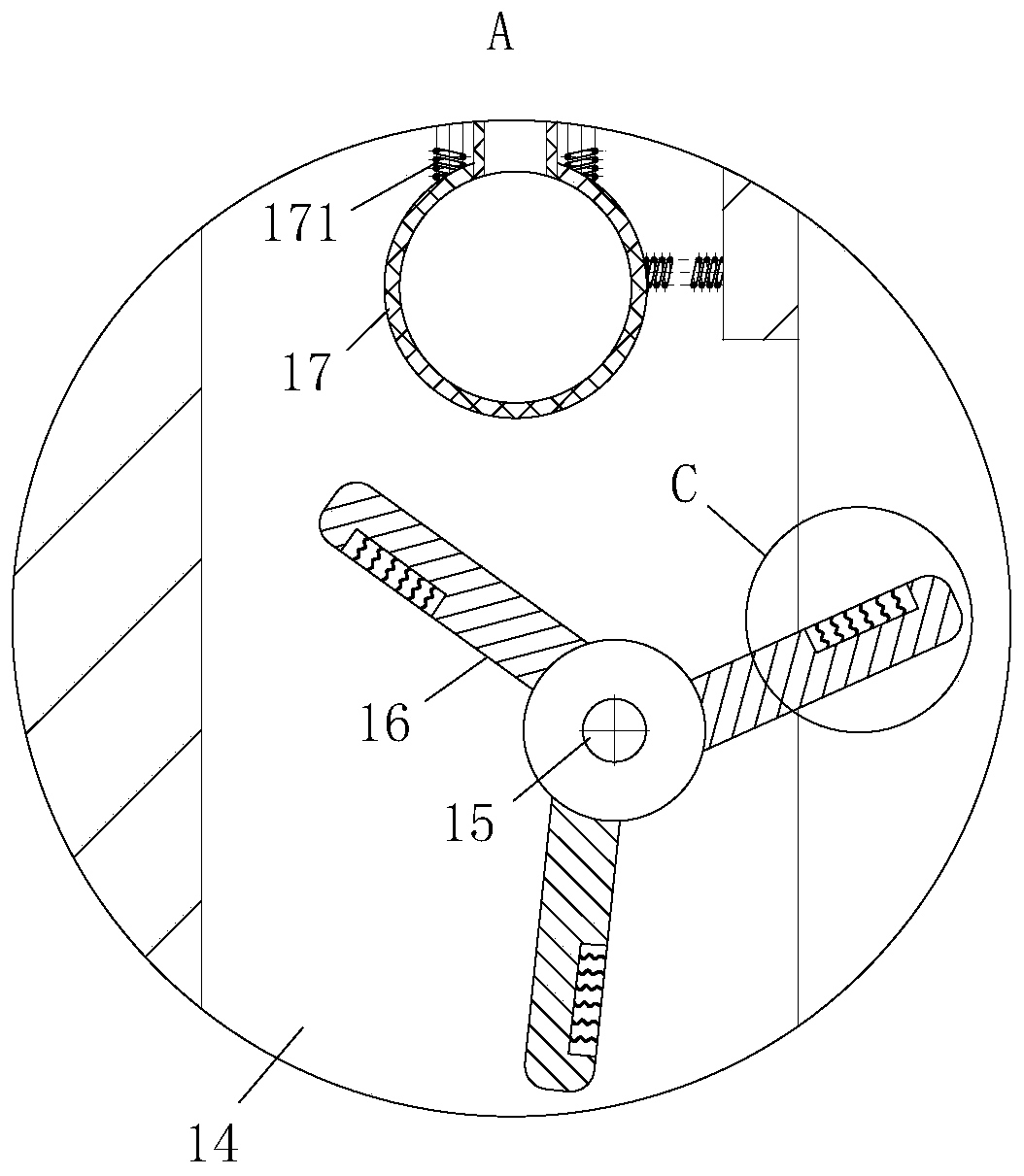

[0028] As an embodiment of the present invention, the side wall of the rotating plate 16 is provided with a No. 2 notch 161, and a group of arc-shaped plates 162 are connected inside the No. 2 notch 161; When the air flow impacts and squeezes the side of the rotating plate 16, the arc-shaped plate 162 provided at the second notch 161 strengthens the contact area between the air flow and the rotating plate 16, so that the rotating plate 16 is subjected to the impact force of the air flow to become larger, thereby accelerating The rotation of the rotating plate 16 prevents the insufficient airflow of the vacuum pipe 12 from causing the rotating plate 16 to rotate slowly, thus affecting the extrusion and leveling of the protrusions of the packaging box by the sliding plate 3, which greatly improves the working performance of the packaging box forming machine.

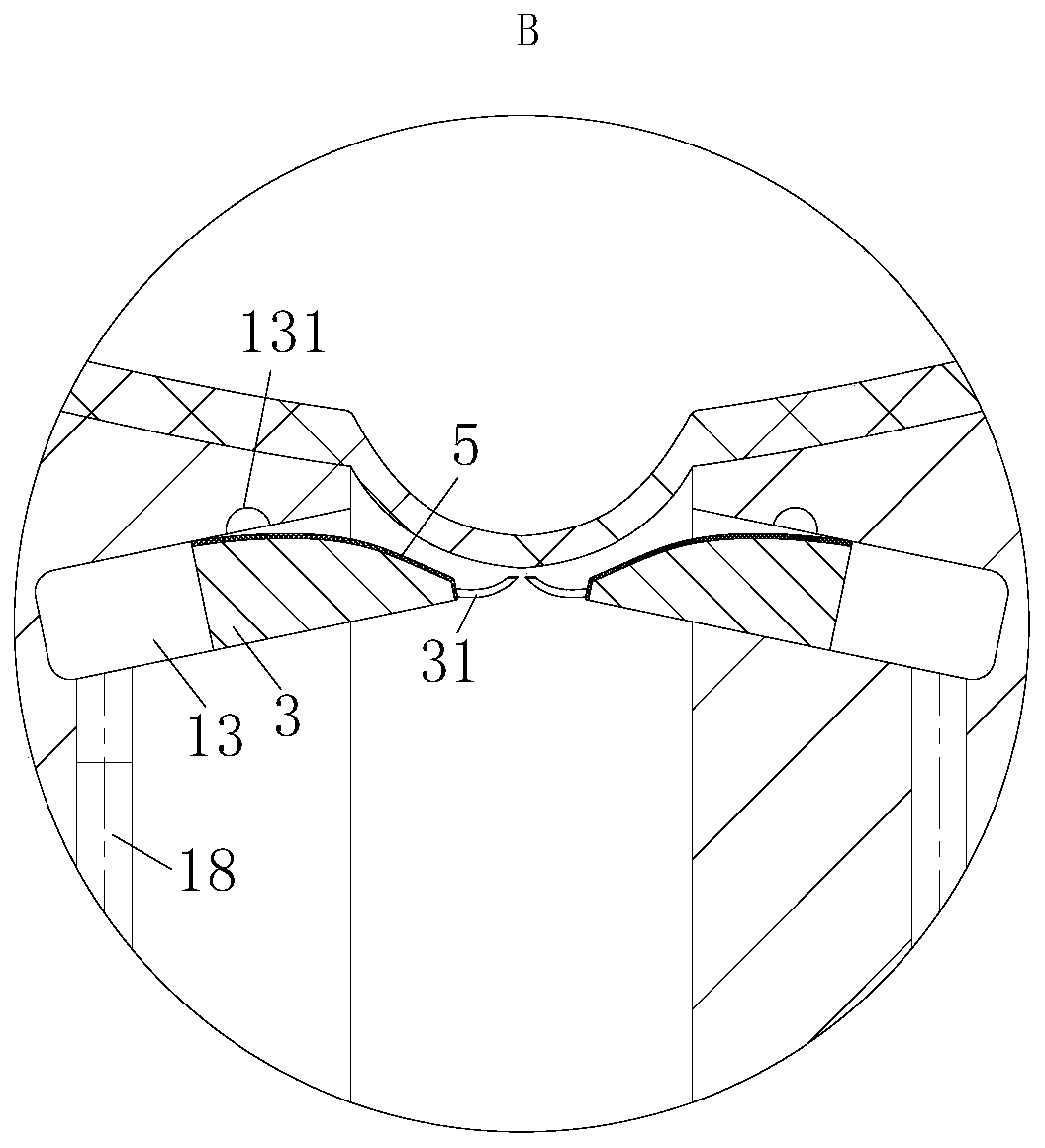

[0029] As an embodiment of the present invention, the elastic plate 31 and the top surface of the slide plate 3 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com