Double-type corner protector automatic production line

An automatic production line and corner guard technology, applied in the field of machinery, can solve the problems of wasting labor, unable to meet automatic production, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

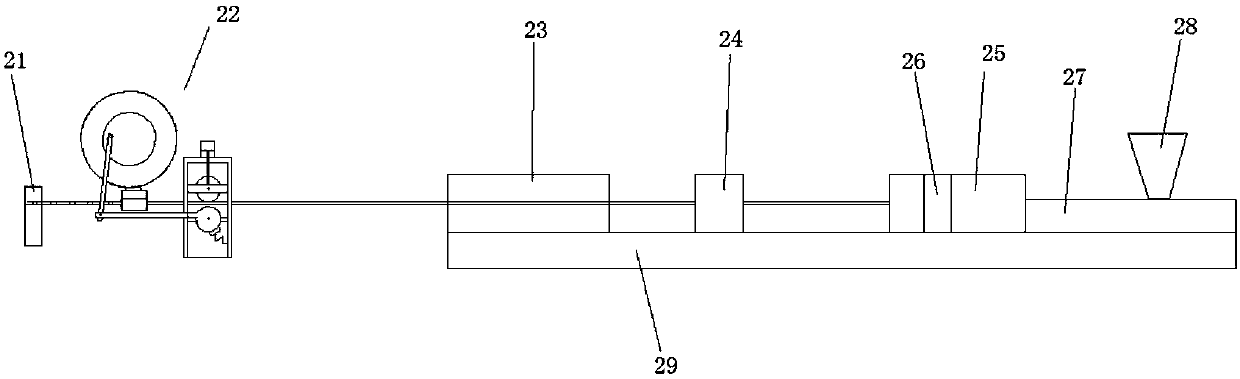

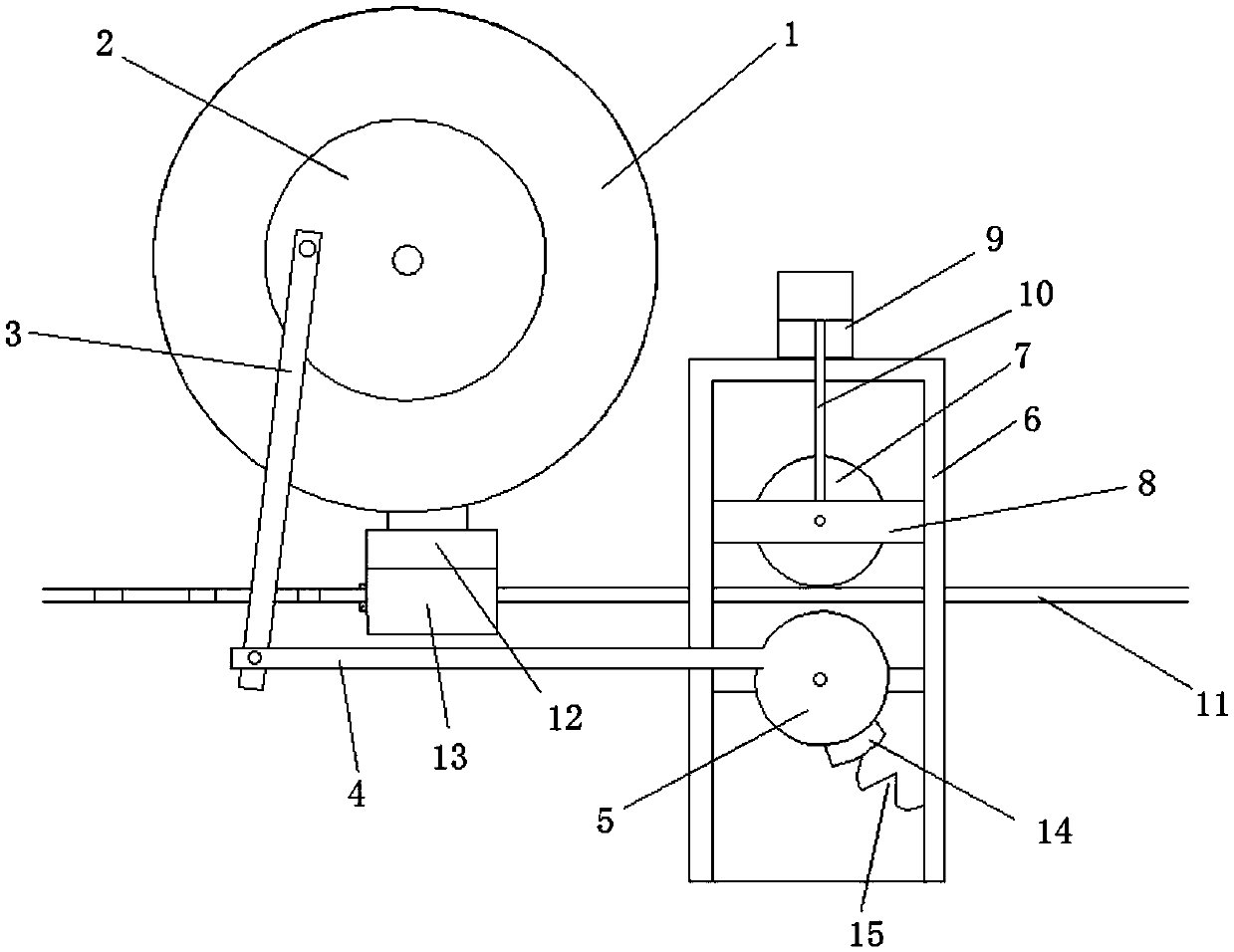

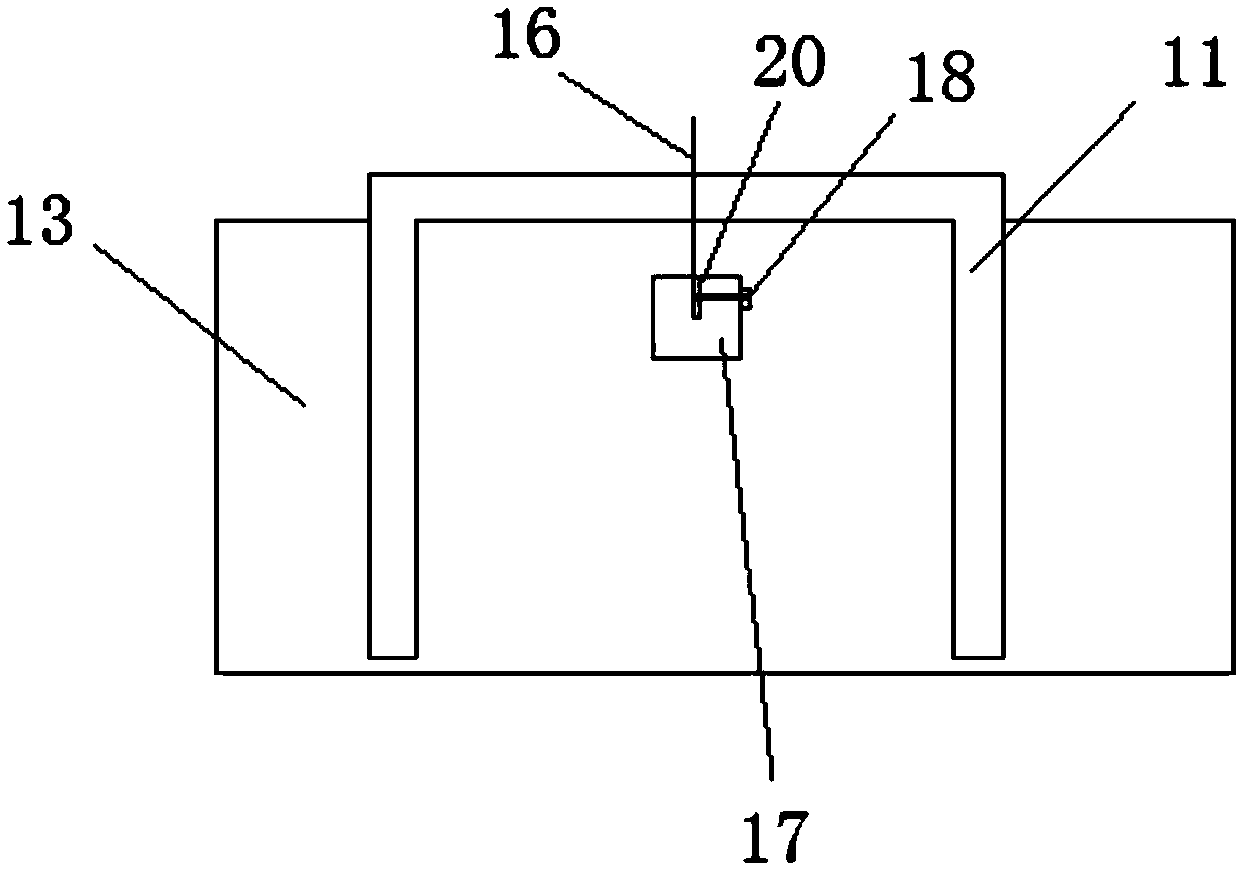

[0012] The present invention is specifically described below in conjunction with accompanying drawing, as shown in the figure, the present invention comprises screw extruder 27, molding die 25, setting die 24, water tank 23, punching cutting device 22 and reel device 21; Machine 27, shaping die 25, setting die 24, water tank 23 are fixed on the frame 29 in turn; Material enters in the screw extruder 27 by the feeding port 28 that is arranged on the screw extruder, and the screw extruder heats material After homogenization and homogenization, it is transported to the forming die 25 and extruded from the forming die 25, then enters the shaping die 24 for finalization, after being cooled by the water tank 23, it is punched and cut 22 by the punching and cutting device, and finally wound on the reel device 21 Above; in order to ensure that impurities in the material will not enter the forming mold, a filter unit 26 is set in the forming mold.

[0013] Described screw extruder 27, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com