Sowing machine capable of carrying out compacting, reverse rotation, ditching and fertilizing before rotary tillage and straw breaking and working method thereof

A technology for ditching sowing and working methods, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of high power consumption, increased planting operation cost, low degree of straw crushing, etc., and can improve the quality of sowing. and operation efficiency, beneficial to emergence and development, and the effect of improving water use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

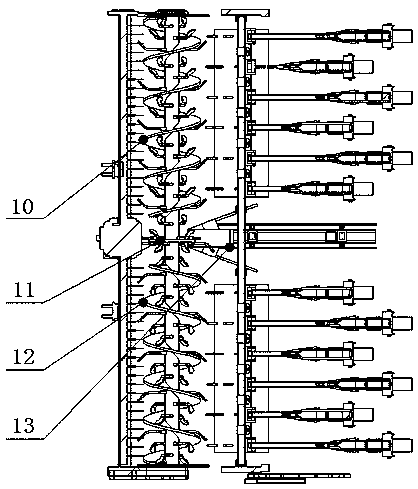

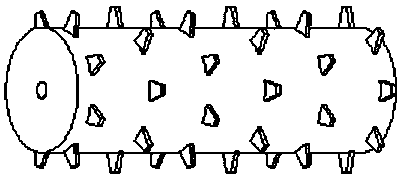

[0034] A kind of rotary tillage crushing bar before sowing, suppressing reverse rotation, ditching, sowing and fertilizing rice and wheat planter, firstly, after fertilizing by the fertilization device 8, the reverse rotary tiller 2 performs rotary tillage on the soil, and the straw brought up and the moving blade on the soil retaining cover 1 Cooperate with the chopped straw, and at the same time, the ditch opening device 11 in the middle of the rotary tiller opens the drainage ditch, and the screw soil delivery device auger 10 assembled coaxially with the rotary tiller transports a large amount of soil brought up by the drainage ditch outward, effectively preventing Blocking soil. After the ditch opening device 11 has opened the drainage ditch, the ditch protection device 13 at the middle rear part stabilizes the ditch shape. After completing the operation of rotary tillage ditching broken bars, a kind of pressing roller 3 before sowing is designed to suppress before sowing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com