Coated rolling element bearing

A technology for rolling elements and bearings, applied to bearings, rotating parts that resist centrifugal force, bearing components, etc., can solve problems such as coating peeling, and achieve the effects of low coating temperature, low friction, and high anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

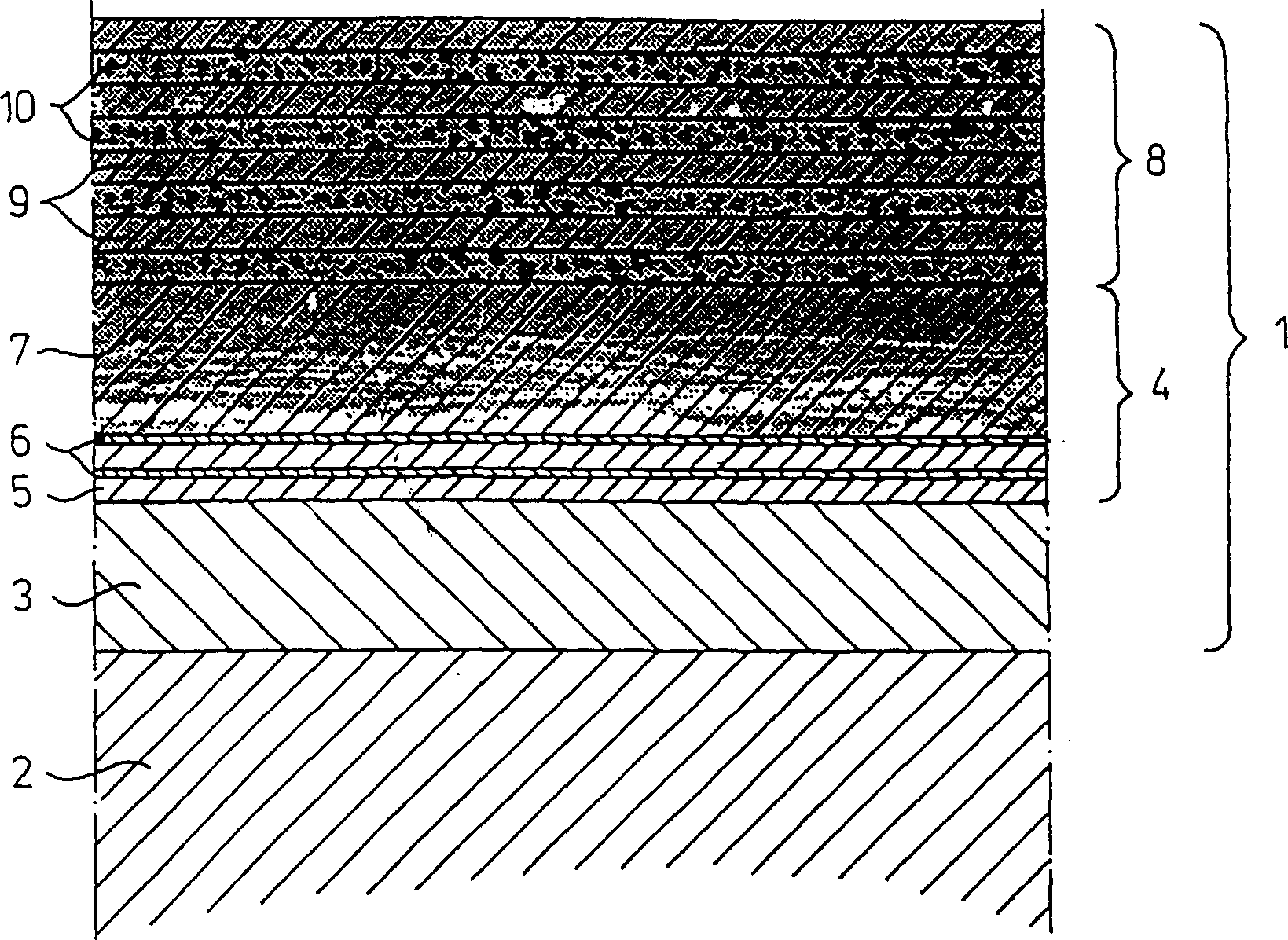

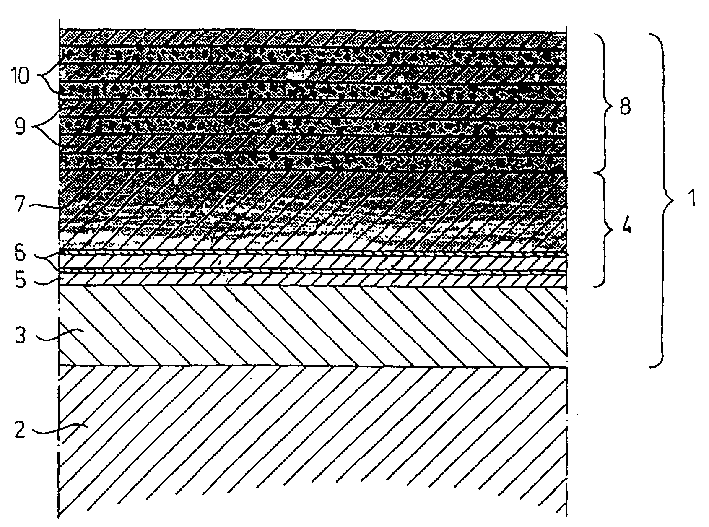

[0026] figure 1 Shows a cross-sectional view of the rolling elements of a rolling element bearing or the outer layer of the raceway of a ring. The entire exterior is generally indicated with reference numeral 1 and is applied to a substrate 2, for example bearing steel.

[0027] Said entire exterior 1 comprises an intermediate metallic interlayer 3 applied directly to the substrate 2, a transition zone 4 following the intermediate metallic interlayer 3, and a metal-mixed-diamond-like carbon coating 8. The transition region 4 comprises a multilayer transition region obtained by alternating metal carbide layers 5 and metal layers 6 . Subsequently, towards the multilayer structure 8 , a smooth transition region 7 results. The transition region 7 provides a smooth transition from metal carbide to a mixture of metal carbide and diamond-like carbon. The multilayer structure 8 comprises alternating metal carbide layers 9 and diamond-like carbon layers 10 .

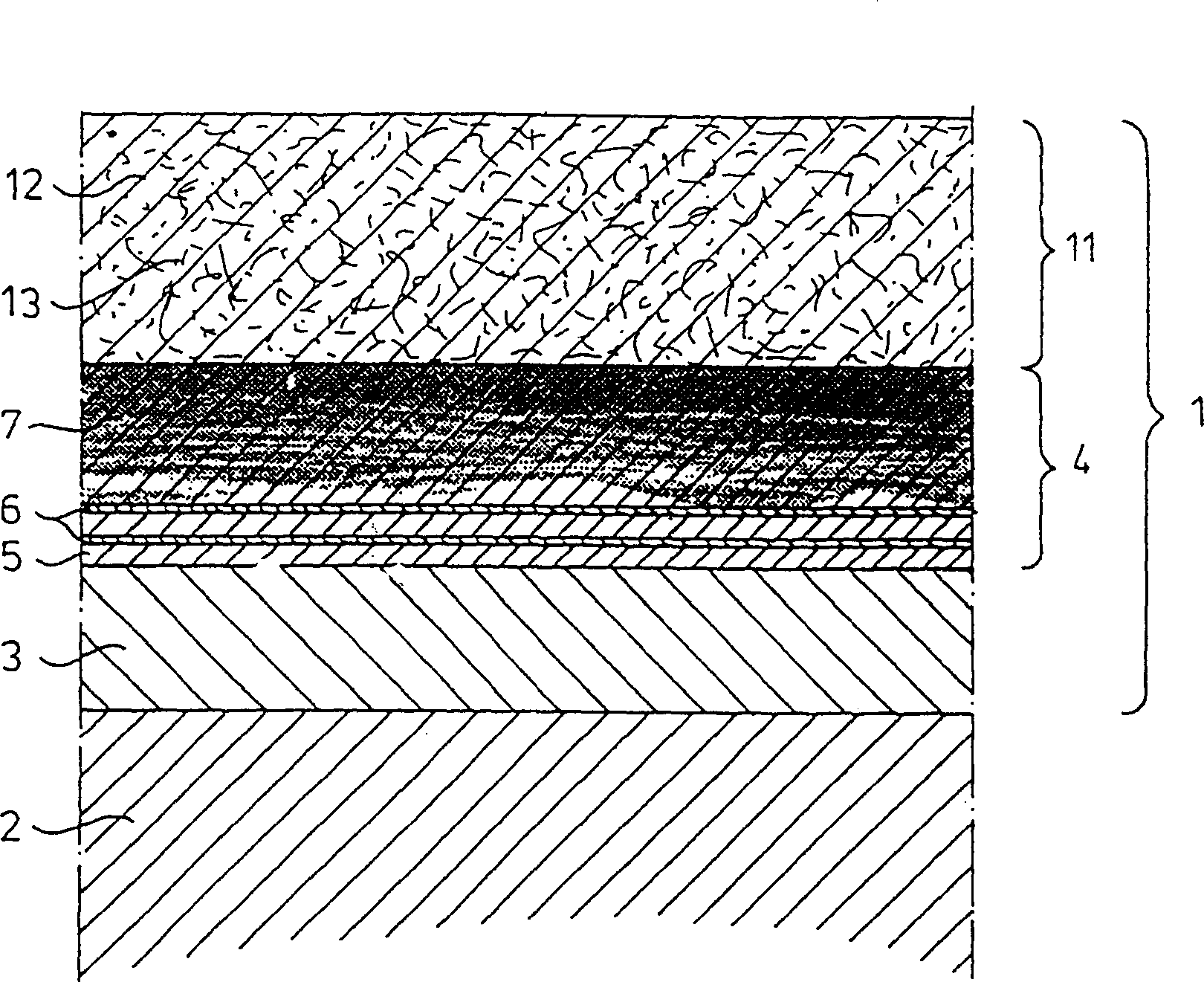

[0028] figure 2 A c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap