Biomass combustible gas extraction method and device

An extraction method and biomass technology, applied in the manufacture of combustible gas, petroleum industry, etc., to achieve the effects of improving utilization efficiency, improving the quality of extracted combustible gas, and optimizing the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

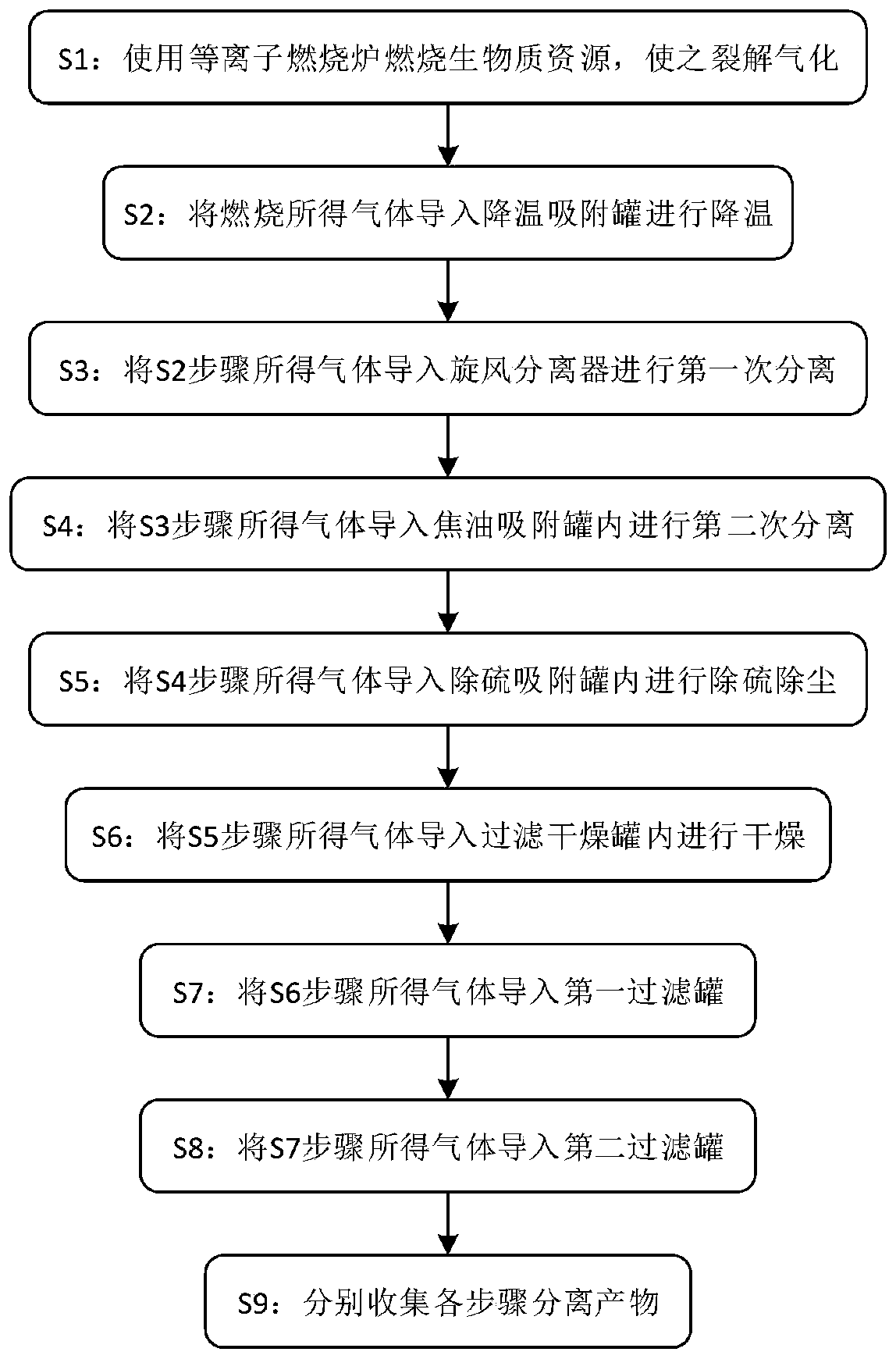

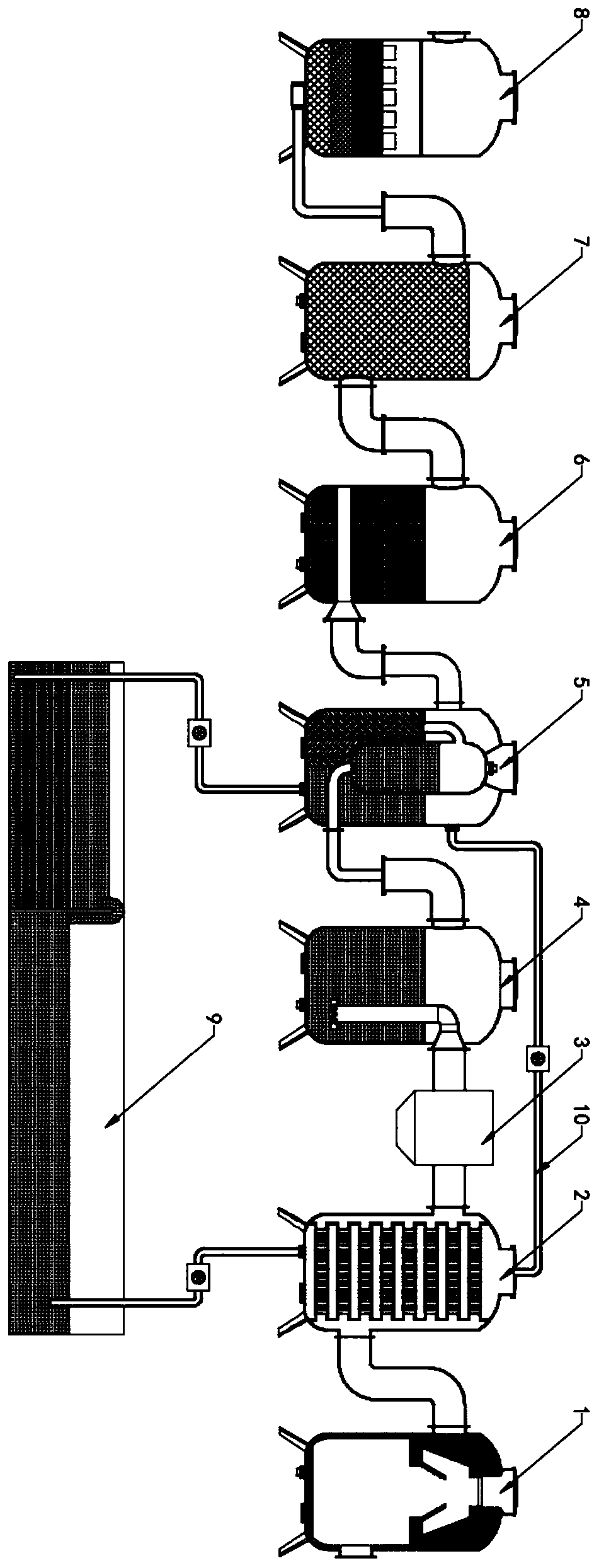

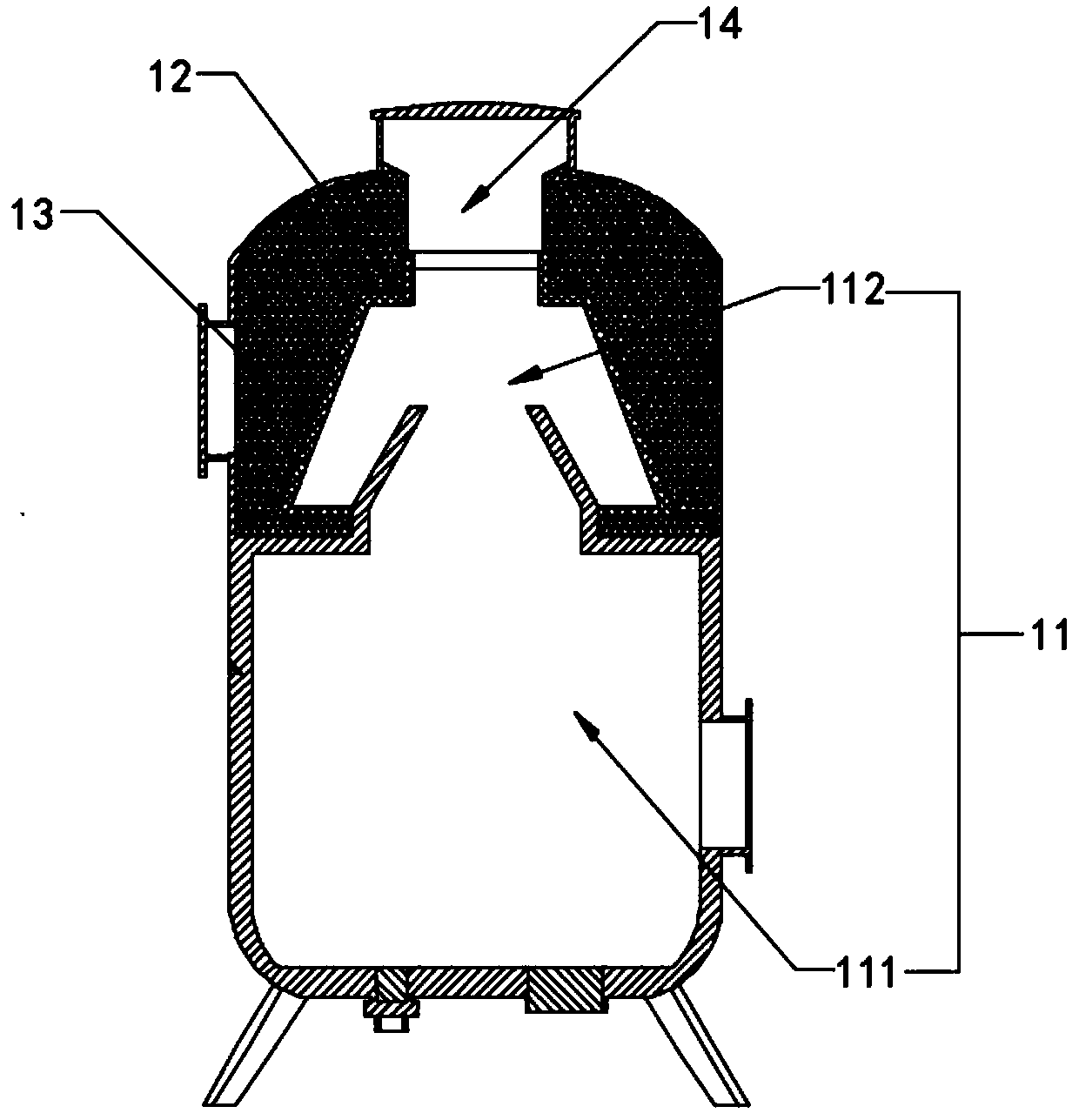

[0080] Such as Figure 1-Figure 4As shown, the present invention provides a kind of biomass combustible gas extraction method and extraction equipment, and described extraction method comprises the following steps:

[0081] S1: Use the plasma combustion furnace 1 to burn biomass resources to crack and gasify them. The combustion temperature in the plasma combustion furnace 1 is 1000°C-1600°C, the combustion time is 2h, and the pressure in the furnace is 5MPa;

[0082] S2: Introduce the combustion gas into the cooling adsorption tank 2 to lower the temperature. The temperature of the passing gas in the cooling adsorption tank 2 is reduced to 100° C., and the cooling time is 2 hours;

[0083] S3: import the gas obtained in step S2 into the cyclone separator 3 for the first separation, and the first separation time is 45 minutes;

[0084] S4: introducing the gas obtained in step S3 into the tar adsorption tank 4 for a second separation, the second separation time is 90 minutes; ...

Embodiment 2

[0095] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of biomass combustible gas extraction method and extraction equipment, and described extraction method comprises the following steps:

[0096] S1: Use the plasma combustion furnace 1 to burn biomass resources to crack and gasify them. The combustion temperature in the plasma combustion furnace 1 is 1100°C-1700°C, the combustion time is 1.5h, and the pressure in the furnace is 5.5MPa;

[0097] S2: Introduce the combustion gas into the cooling adsorption tank 2 to lower the temperature. The temperature of the passing gas in the cooling adsorption tank 2 is reduced to 150° C., and the cooling time is 3 hours;

[0098] S3: introducing the gas obtained in step S2 into the cyclone separator 3 for the first separation, and the first separation time is 30 minutes;

[0099] S4: introducing the gas obtained in step S3 into the tar adsorption tank 4 for second separation, the second separation time is 60 m...

Embodiment 3

[0110] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of biomass combustible gas extraction method and extraction equipment, and described extraction method comprises the following steps:

[0111] S1: Use the plasma combustion furnace 1 to burn biomass resources to crack and gasify them. The combustion temperature in the plasma combustion furnace 1 is 1200°C-1800°C, the combustion time is 2 hours, and the furnace pressure is 6MPa;

[0112] S2: Introduce the combustion gas into the cooling adsorption tank 2 to lower the temperature. The temperature of the passing gas in the cooling adsorption tank 2 is reduced to 200° C., and the cooling time is 4 hours;

[0113] S3: import the gas obtained in step S2 into the cyclone separator 3 for the first separation, and the first separation time is 45 minutes;

[0114] S4: introducing the gas obtained in step S3 into the tar adsorption tank 4 for a second separation, the second separation time is 90 minutes; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com