Hoisting method of cable-stayed suspended tubular busbar

A technology of tubular busbar and hoisting method, which is applied in the installation of busbar, fully enclosed busbar device, cable installation, etc. It can solve the problems of high difficulty in installation of 500KV substation, inability to ensure the progress of substation installation, complicated hoisting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

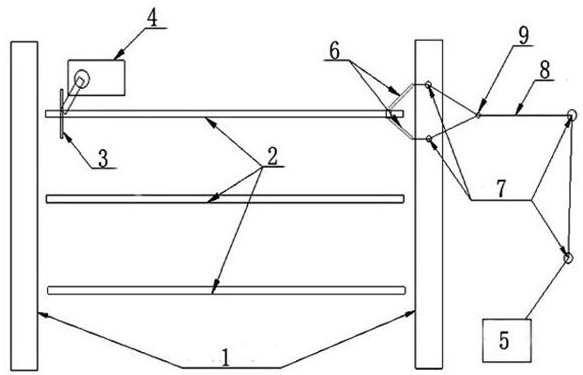

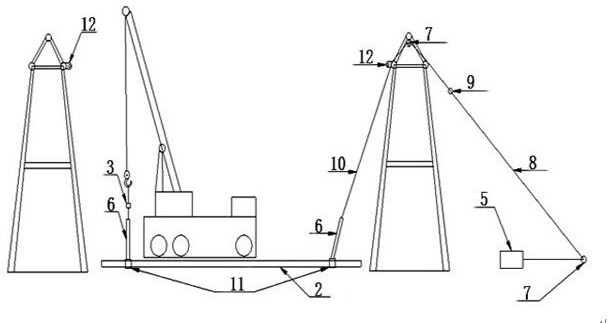

[0029] Embodiment: A hoisting method of a cable-stayed suspended tubular busbar, the steps are as follows: The preparatory work before hoisting includes: 1) The height of the civil gantry frame 1 according to the acceptance is 23m, and the distance between the two civil gantry frames 1 is 29m , the welding length of the tubular busbar 2 is determined to be 22m, and a 25-ton truck crane 4 and a winch mill 5 are used for hoisting.

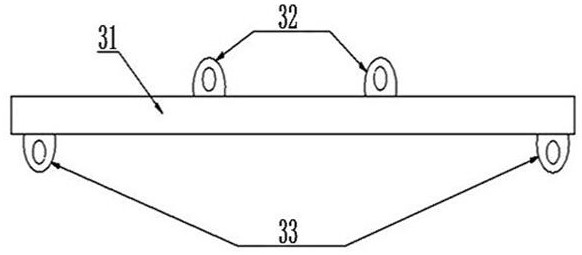

[0030] 2) According to the design drawings and hoisting plan, choose 4 strings per phase, 34 pieces of insulator strings per string 6, four 3-ton sliders 7, one 5-ton lifting ring 9, one 60m φ12.5 steel wire rope 10, four A 30m hemp rope, a traction wire rope 8, two suspension fittings 11 and other spreaders and installation tools are installed,

[0031] 3) Check that all installation tools are in good condition, and the surface of the hanging hardware 11 should be free from cracks and rust, and the anti-loosening accessories are complete.

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com