Flue baffle door nano heavy corrosion resistance process

A kind of baffle door and flue air duct technology, which is applied to special surfaces, devices that apply liquid to the surface, coatings, etc., can solve the problems of baffle door rust, high equipment cost, anti-corrosion failure, etc., and reduce equipment costs. , Easy to operate, easy to repair effect

Pending Publication Date: 2019-10-29

无锡市华通环保设备有限公司

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The cost of the equipment is very high, and the manufacturing process is complicated; if you are not careful, the anticorrosion will fail, and the baffle door working in a strong corrosive environment will rust until it is damaged

Even when problems are detected early, repairs can be cumbersome

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

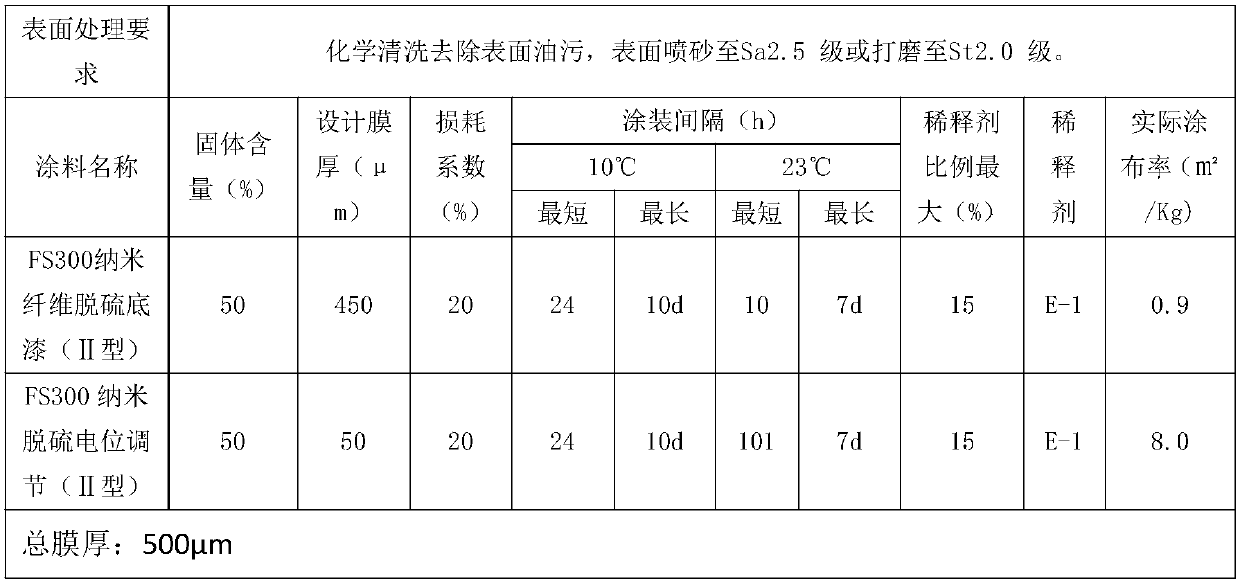

[0049] Specific examples are as follows in Table 1:

[0050] Table I:

[0051]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a flue baffle door nano heavy corrosion resistance process. The nano heavy corrosion resistance process comprises coating and steps, wherein the coating comprises two layers ofpriming paint and finishing paint, the priming paint adopts FS300 nano fiber desulfurization double-component priming paint (type II), and the finishing paint adopts FD300 nano fiber desulfurizationelectric potential adjusting paint (type II); the steps comprises surface pretreatment and coating process, wherein the first priming coating of the coating process is carried out within 4 hours afterthe surface treatment is finished; all-component paint vehicle is fully and uniformly stirred before preparation by adopting extrusion coating, spraying coating or roller coating; and after coating construction is completed, the coating is maintained. According to the flue baffle door nano heavy corrosion resistance process, the operation is easy and convenient during product production, the repair is easy during local damage, the service life is prolonged, and the cost is low.

Description

technical field [0001] The invention belongs to the technical field of mechanical equipment, and relates to a novel anti-corrosion process for a flue baffle door of a boiler flue gas purification treatment system in a coal-fired power plant, in particular to a nano-heavy anti-corrosion process for a flue air duct baffle door. Background technique [0002] The flue baffle door is an important auxiliary equipment of the boiler flue gas treatment system. It is installed in the boiler of the thermal power plant or the flue air system of the power department of other enterprises for the purpose of intercepting the working medium. For the baffle door installed in the low-temperature flue, the existing technology is all through the anti-corrosion process of lining the nickel-based alloy to achieve a higher service life. The cost of the equipment is very high, and the manufacturing process is complicated; a little carelessness will cause the anticorrosion failure, and the baffle doo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B05D5/00B05D7/00B05D7/14

CPCB05D5/00B05D7/54B05D7/14

Inventor 张红旗

Owner 无锡市华通环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com