Optical detection system and method

An optical detection and light beam technology, applied in the optical field, can solve problems such as inadaptability, large influence of spectrum analysis method, and large noise interference, etc., and achieve the effects of strong practicability, simple deployment, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

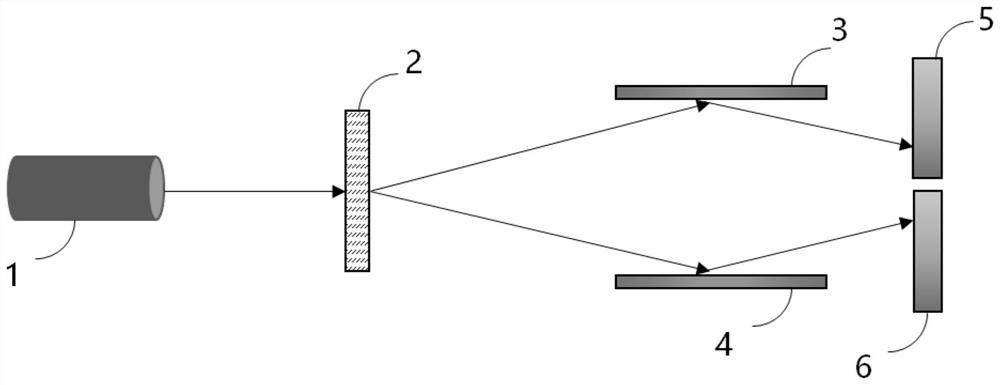

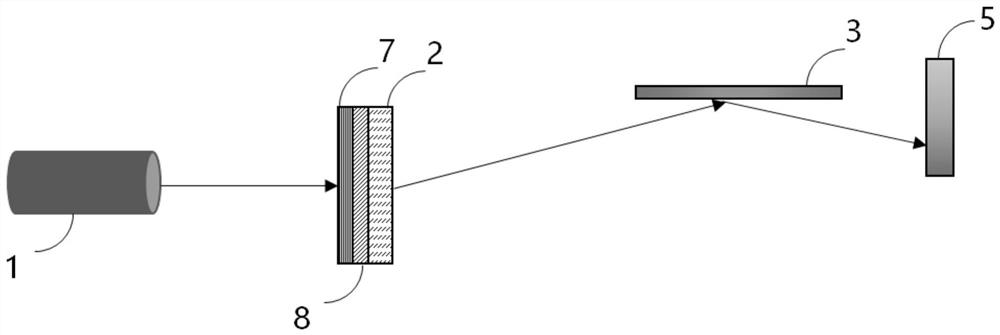

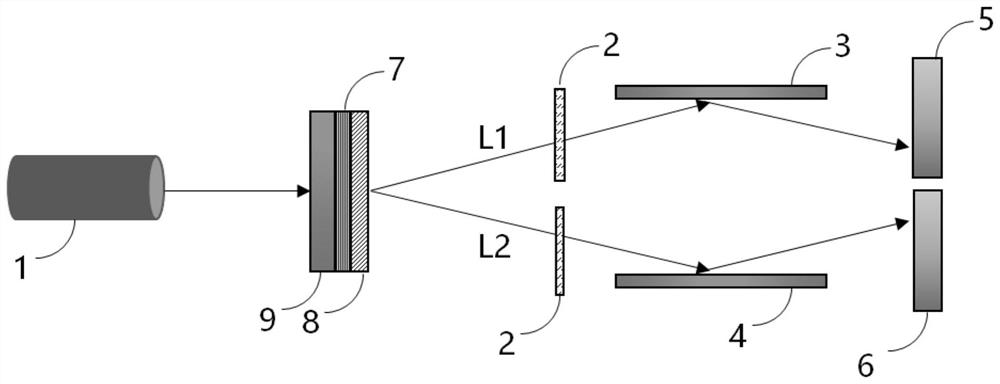

[0025] This embodiment discloses an optical detection system, including: a multispectral light source, a deflection device, and a data processing device.

[0026] Among them, the deflection device in this embodiment is located between the multi-spectral light source and the object to be measured, and is used to deflect the beams of different wavelengths emitted from the multi-spectral light source to directions corresponding to the wavelengths, and to deflect the light beams of different wavelengths The light beam is emitted to the object to be measured.

[0027] In this embodiment, the data processing device is used to: receive the light beam reflected by the surface of the object to be measured, and compare the reflected spectrum with the reference calibration spectrum reflected by the corresponding standard part to determine the wavelength of the difference, and then according to the difference Calculate the spatial coordinates corresponding to the surface defects of the ob...

Embodiment 2

[0039] Corresponding to the above embodiments, this embodiment discloses an optical detection method, including the following steps:

[0040] Step S1, setting a multi-spectral light source, and setting a deflection device between the multi-spectral light source and the object to be measured.

[0041] Step S2. The spectrum deflection device deflects the beams of different wavelengths emitted from the multi-spectral light source to directions corresponding to the wavelengths, and emits the deflected beams of different wavelengths to the object to be measured.

[0042] Step S3, receiving the light beam reflected by the surface of the object to be measured, and comparing the reflected spectrum with the reference calibration spectrum reflected by the corresponding standard part to determine the wavelength of the difference, and then calculate the to-be-measured wavelength according to the wavelength of the difference. The spatial coordinates corresponding to the surface defects of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com