A Defect Detection Method Based on Gradient Multi-threshold Optimization

A multi-threshold optimization and defect detection technology, applied in optical testing flaws/defects, etc., can solve problems such as inaccurate thresholds, complex algorithms, and long optimal thresholding iterations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

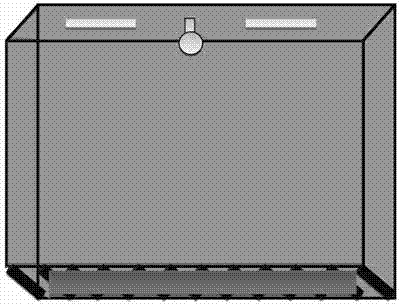

[0042] In the production process, the wood defect detection system such as figure 1As shown, the upper two sides are the light source, the middle one is the acquisition camera, and the lower one is the conveyor belt. The system consists of a conveyor platform, industrial camera, image acquisition card, computer and defect detection software. The camera adopts the Guppy_PRO series industrial camera, which collects grayscale images, and the resolution can be adjusted freely. Since the images involved in defect detection are collected by black and white industrial cameras, they can be directly converted into digital images through the image acquisition card without considering the conversion of color space.

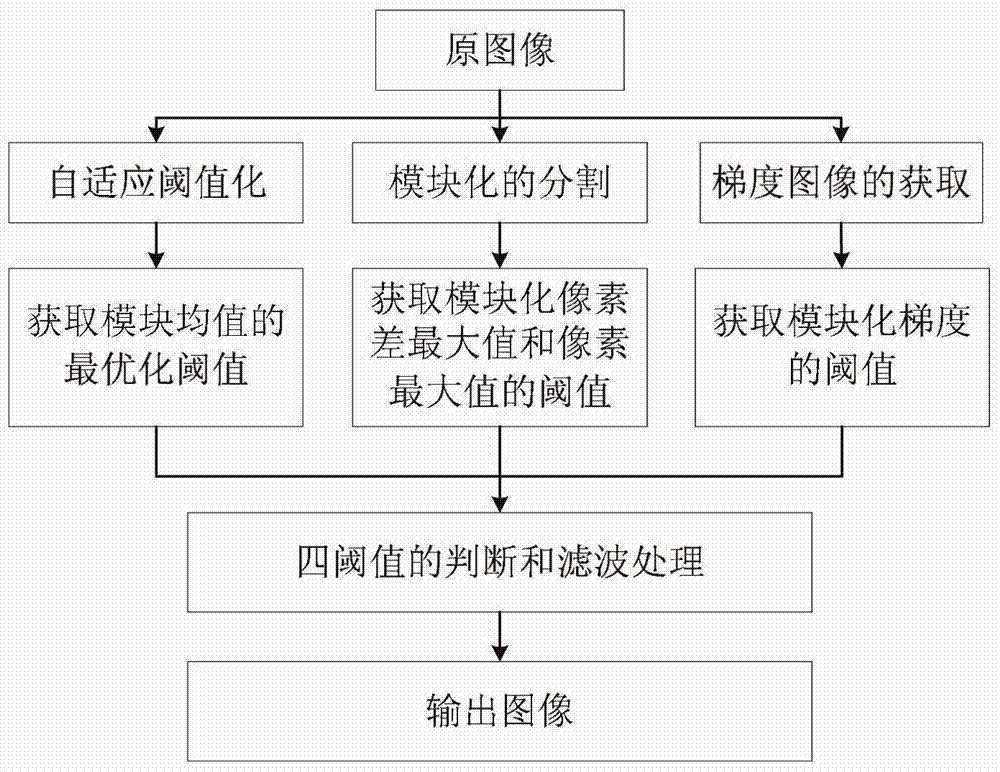

[0043] Such as figure 2 As shown, the present invention is based on a gradient multi-threshold optimized defect detection method, which specifically includes the following steps:

[0044] Step 1. Collect an image of the object to be detected, convert it into a digital ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com