Annular clamping type anti-frozen-off stainless steel pipe fitting

A stainless steel, ring clip technology, applied in the direction of non-detachable pipe connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of increasing friction, increasing the difficulty of connecting, increasing the cost of maintenance, etc., to achieve increased The cost of welding, the connection is stable and reliable, and the effect of increasing welding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

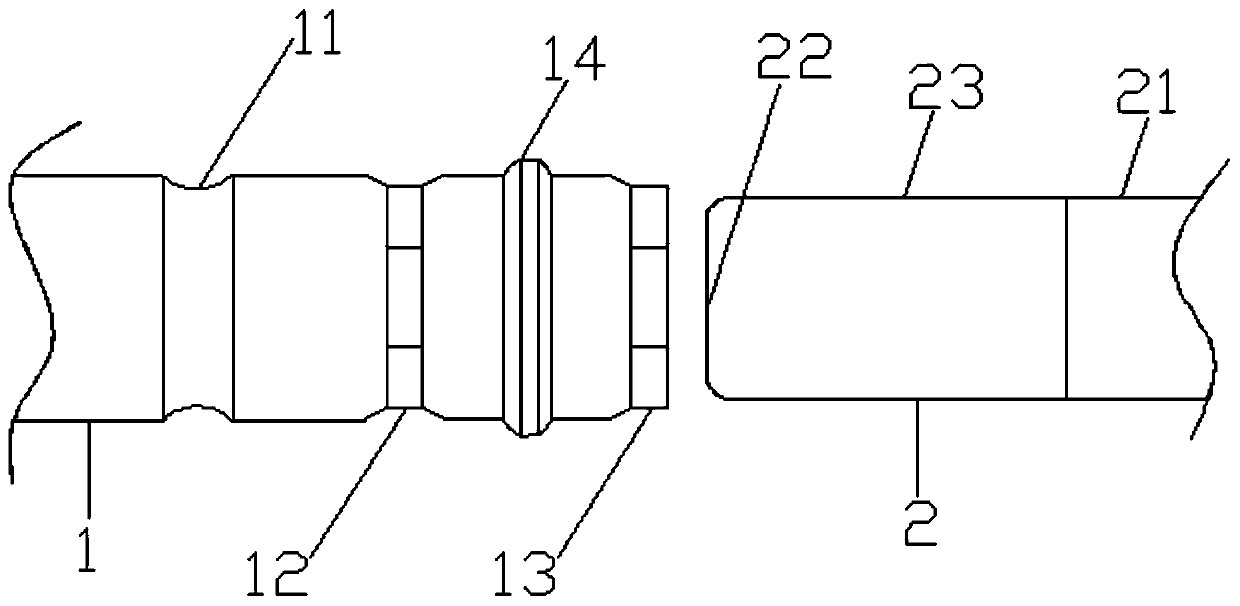

[0034] A ring clasp type anti-freezing stainless steel pipe fitting, including a connector 1 and a connecting pipe 2, the connector 1 includes a limit ring 11, a No. 1 inner snap ring 12, a No. 2 inner snap ring 13, and an outer snap ring 14. The vertical section of snap ring 12 and No. 2 inner snap ring 13 is regular hexagonal shape, connecting pipe 2 includes flow end 21, outlet end 22 and connection end 23, the quantity of outlet end 22 is 2, connection end 23 is connected with Head 1 is soldered. Connection method: the connecting pipe 2 is inserted into the inside of the connecting head 1 until it conflicts with the limiting ring 11 , and the connecting end 23 is welded to the connecting head 1 .

Embodiment 2

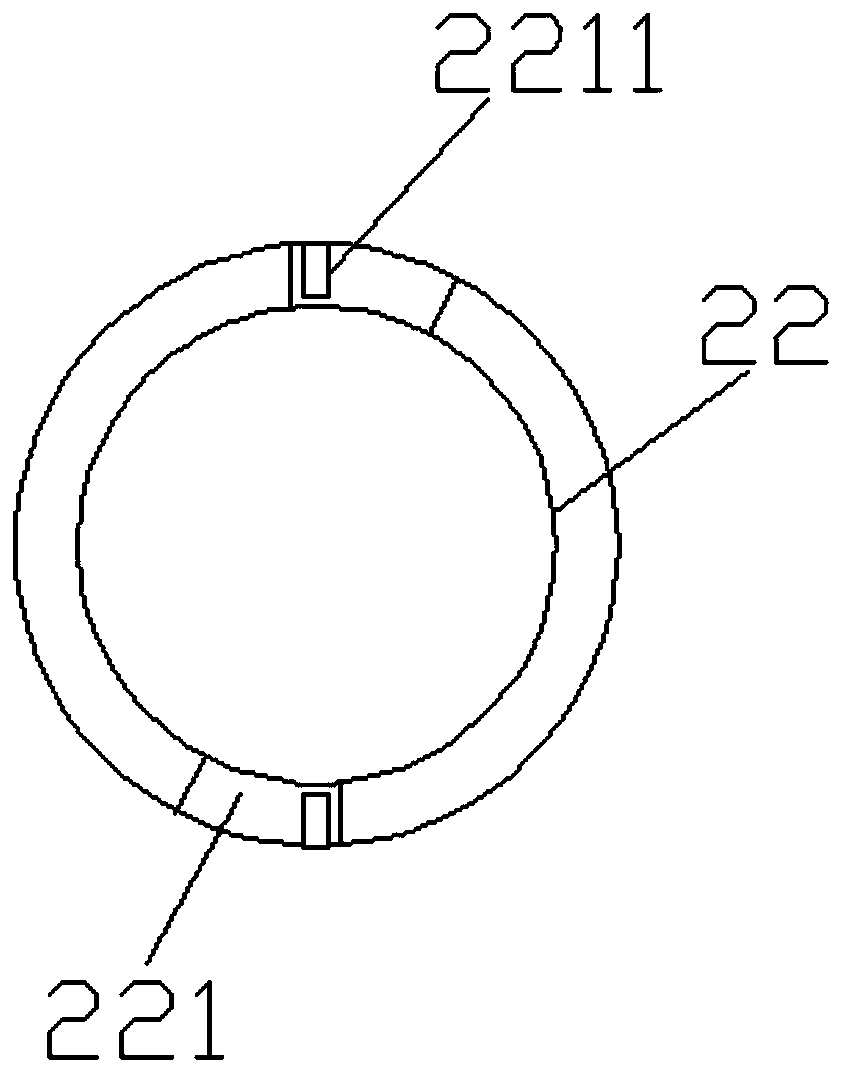

[0036] A ring clasp type anti-freezing stainless steel pipe fitting, including a connector 1 and a connecting pipe 2, the connector 1 includes a limit ring 11, a No. 1 inner snap ring 12, a No. 2 inner snap ring 13, an outer snap ring 14 and an inner positioning rod 15. The vertical sections of the No. 1 inner snap ring 12 and the No. 2 inner snap ring 13 are regular hexagonal shapes. The connecting pipe 2 includes a flow end 21, an outlet end 22 and a connection end 23. The number of outlet ends 22 is 2. The outlet end 22 is provided with a block 221, the inner positioning rod 15 is slidably connected with the block 221, and the outer snap ring 14 is provided with a drum peak 141, the number of the drum peaks 141 is equal to the inner positioning rod 15 and the block 221, and the connecting end 23 is connected to the Connector 1 is welded. Connection method: the connecting pipe 2 is inserted into the inside of the connector 1, the block 221 moves toward the inner positioning ...

Embodiment 3

[0038]A ring clasp type anti-freezing stainless steel pipe fitting, including a connector 1 and a connecting pipe 2, the connector 1 includes a limit ring 11, a No. 1 inner snap ring 12, a No. 2 inner snap ring 13, an outer snap ring 14 and an inner positioning rod 15. The vertical sections of the No. 1 inner snap ring 12 and the No. 2 inner snap ring 13 are regular hexagonal shapes. The connecting pipe 2 includes a flow end 21, an outlet end 22 and a connection end 23. The number of outlet ends 22 is 2. The outlet end 22 is provided with a block 221, and the inner positioning rod 15 is slidably connected with the block 221. The block 221 is provided with a slot, and the slot includes a horizontal slot 2211 and an arc slot 2212. The outer diameter of the section of the inner positioning rod 15 is Less than the width of the horizontal draw-in groove 2211 and the arc-shaped draw-in groove 2212, the height of the inner positioning rod 15 is greater than the depth of the arc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com