Anti-seepage blocking wall and construction method thereof

A barrier layer and wall technology, applied in infrastructure engineering, protection devices, buildings, etc., can solve problems such as environmental pollution, poor anti-seepage barrier effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

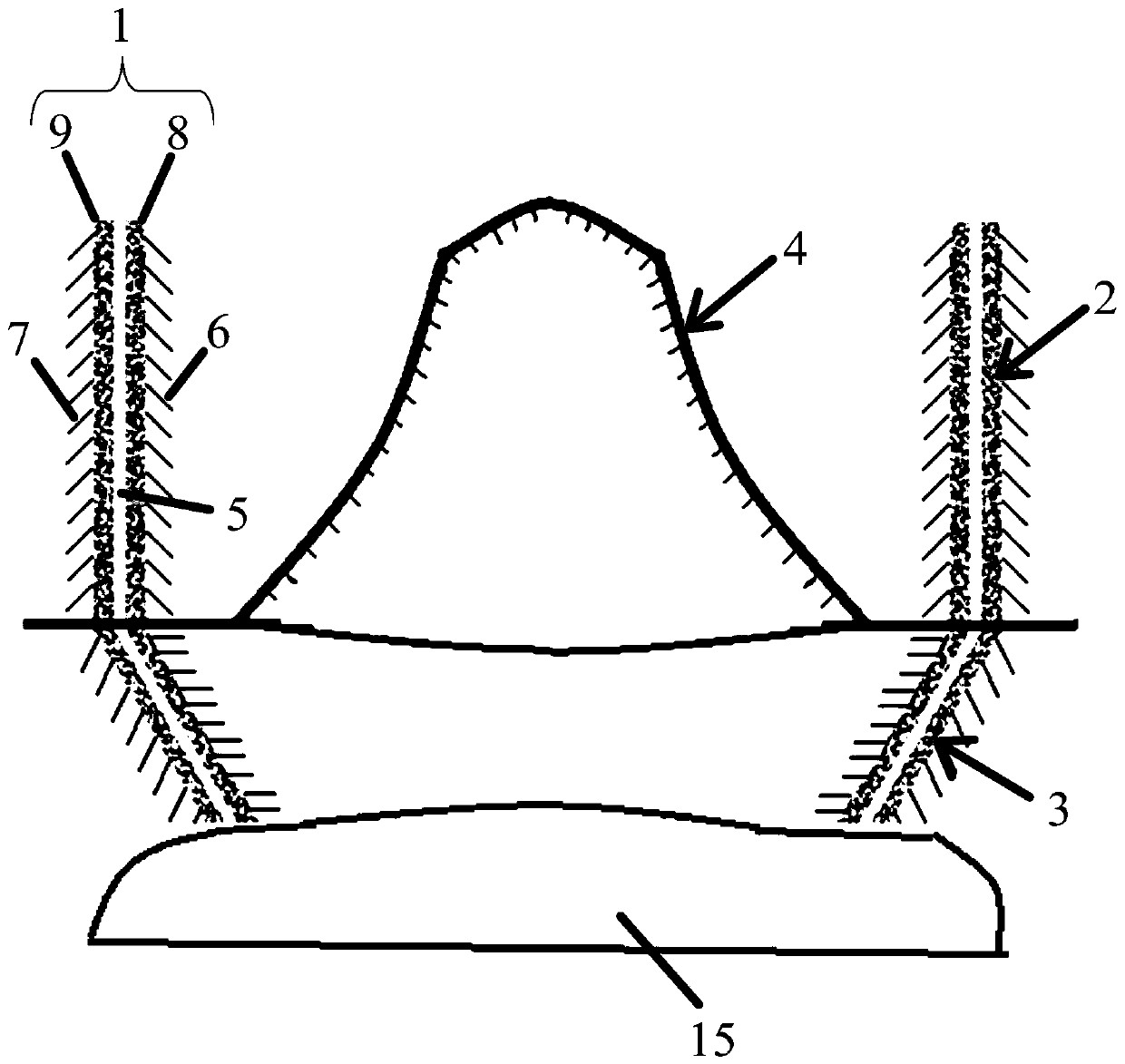

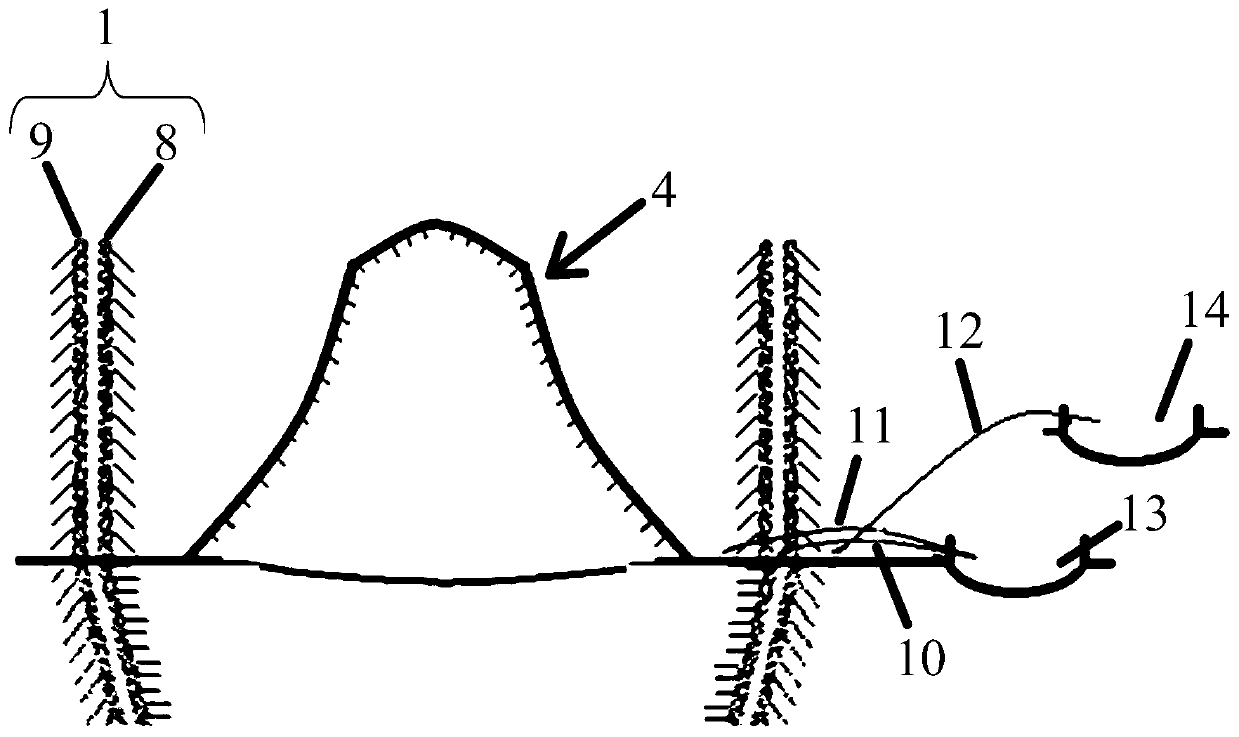

[0040] The embodiment of the present invention provides an anti-seepage barrier wall, such as figure 1 and image 3 shown, which includes:

[0041] The barrier wall 1 includes an upper wall part 2 located above the ground surface and a lower wall part 3 located in the soil on the ground surface. The above barrier wall 1 is respectively arranged in the soil above the ground and below the ground, which can effectively Prevent the solid and liquid pollutants inside the slag yard from seeping out under the seepage of precipitation and groundwater, polluting the environment. The upper wall part 2 is arranged perpendicular to the ground plane, the lower wall part 3 is arranged inclined towards the side close to the slag field, and the lower wall part 3 extends to the bedrock layer 15 below the soil to block the slag Field and pollution source outside. When the lower wall part 3 of the anti-seepage barrier wall located in the lower soil layer is constructed obliquely, the construc...

Embodiment 2

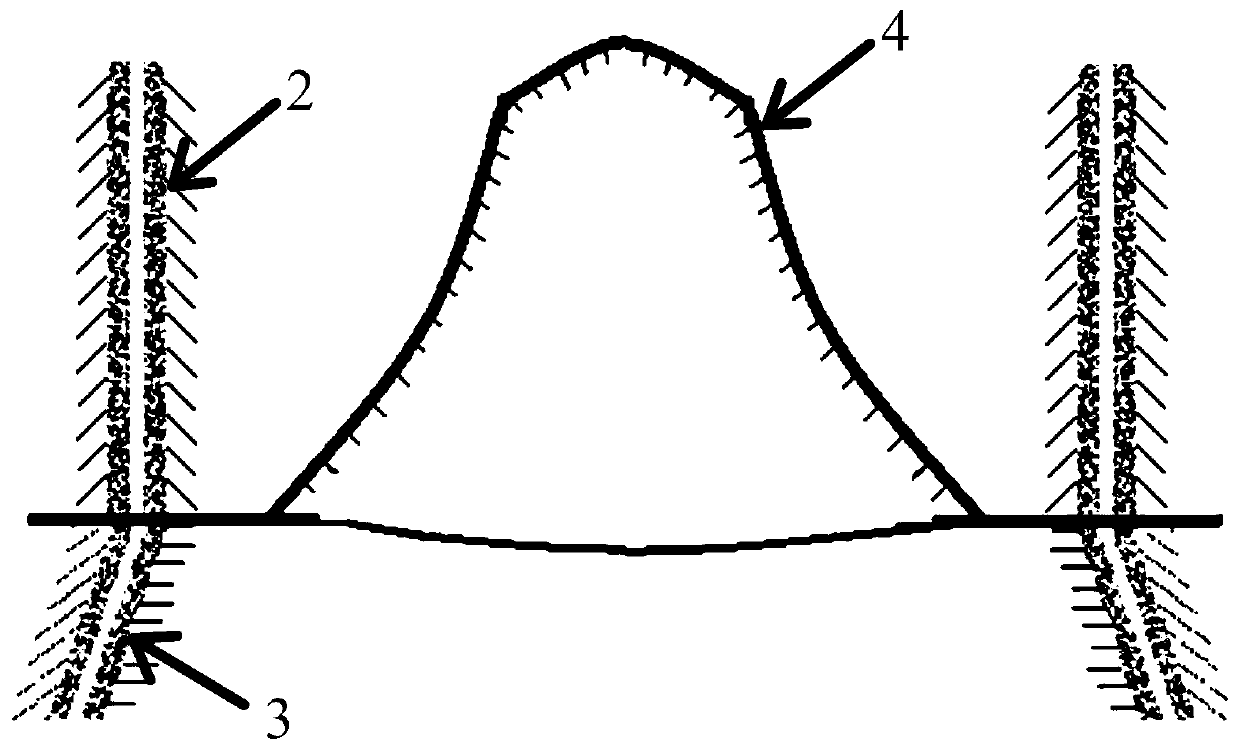

[0053] The difference between this embodiment and embodiment 1 is that, as figure 2 As shown, in the anti-seepage barrier wall provided in this embodiment, the lower wall part 3 is inclined towards the side away from the slag field. The lower wall part 3 is inclined towards the side away from the slag field and extends to the bedrock layer 15 below the soil, which can also play a role in blocking the slag field and the outside world of the pollution source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com