Mixed inclined pulling mechanism and injection mold

A technology of oblique drawing and core pulling, which is applied in the field of hybrid oblique drawing mechanism and injection mold, which can solve the problems of increased mold cost, complex structure, large space occupation, etc., and achieve the effect of enhancing stability and improving the limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

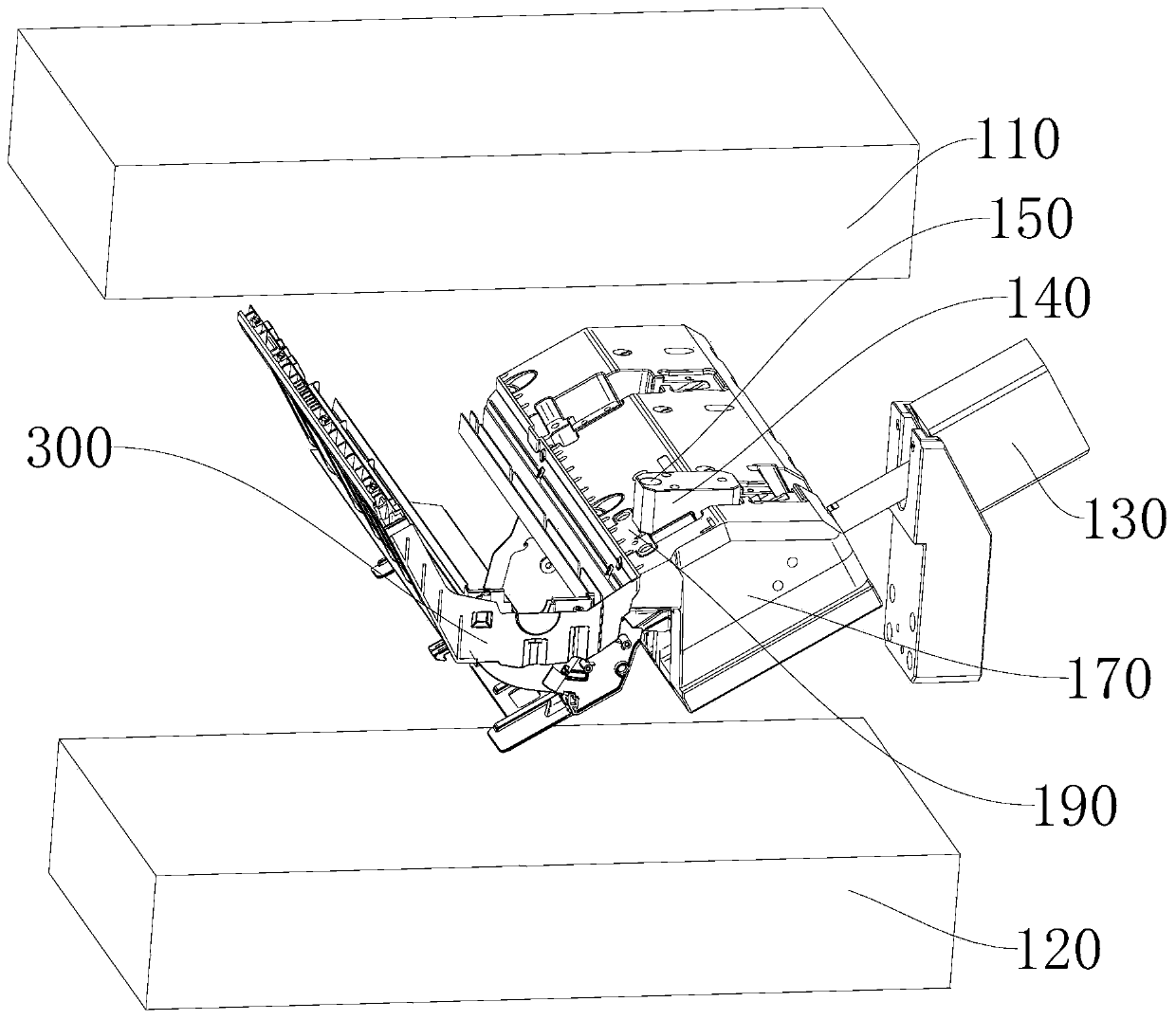

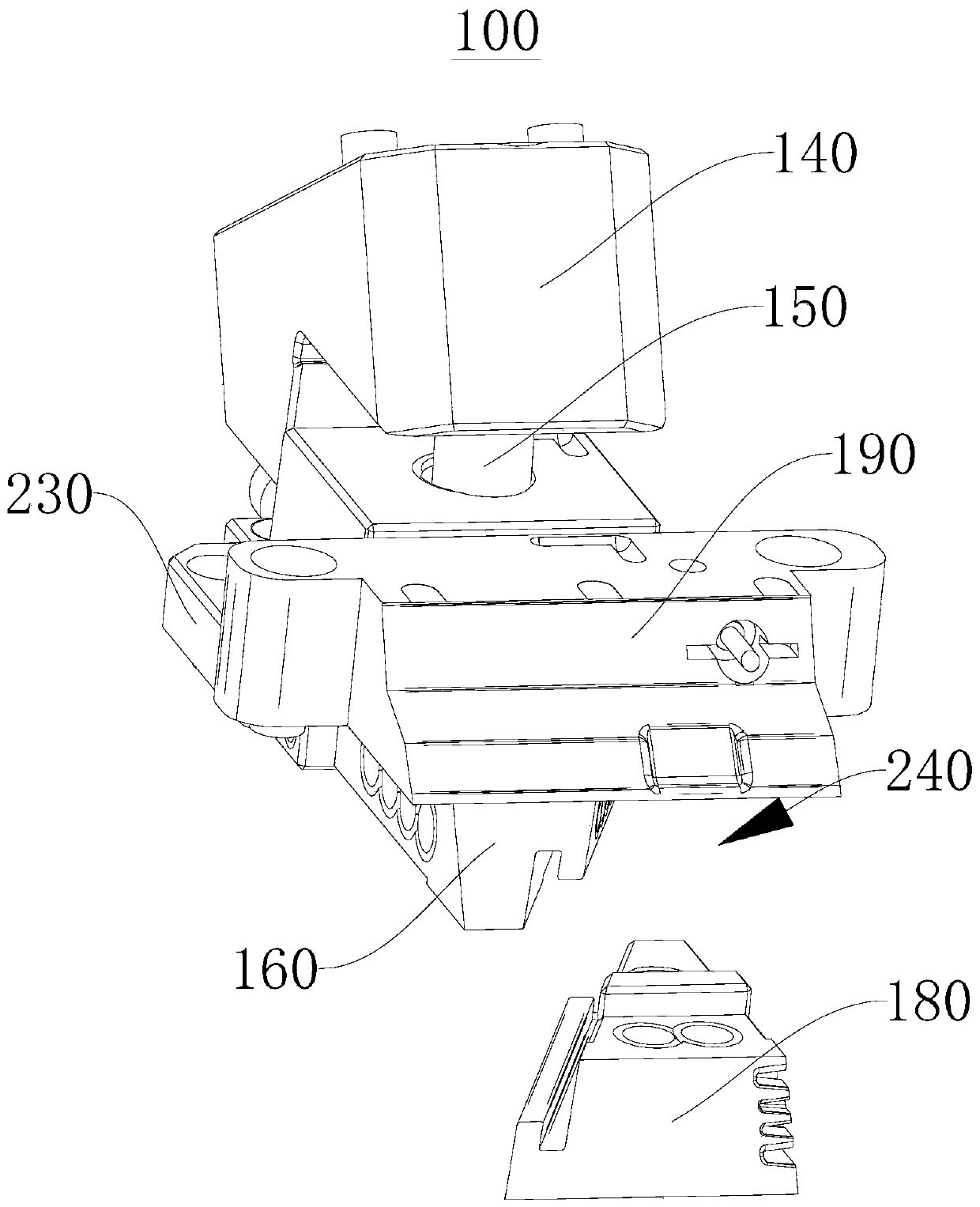

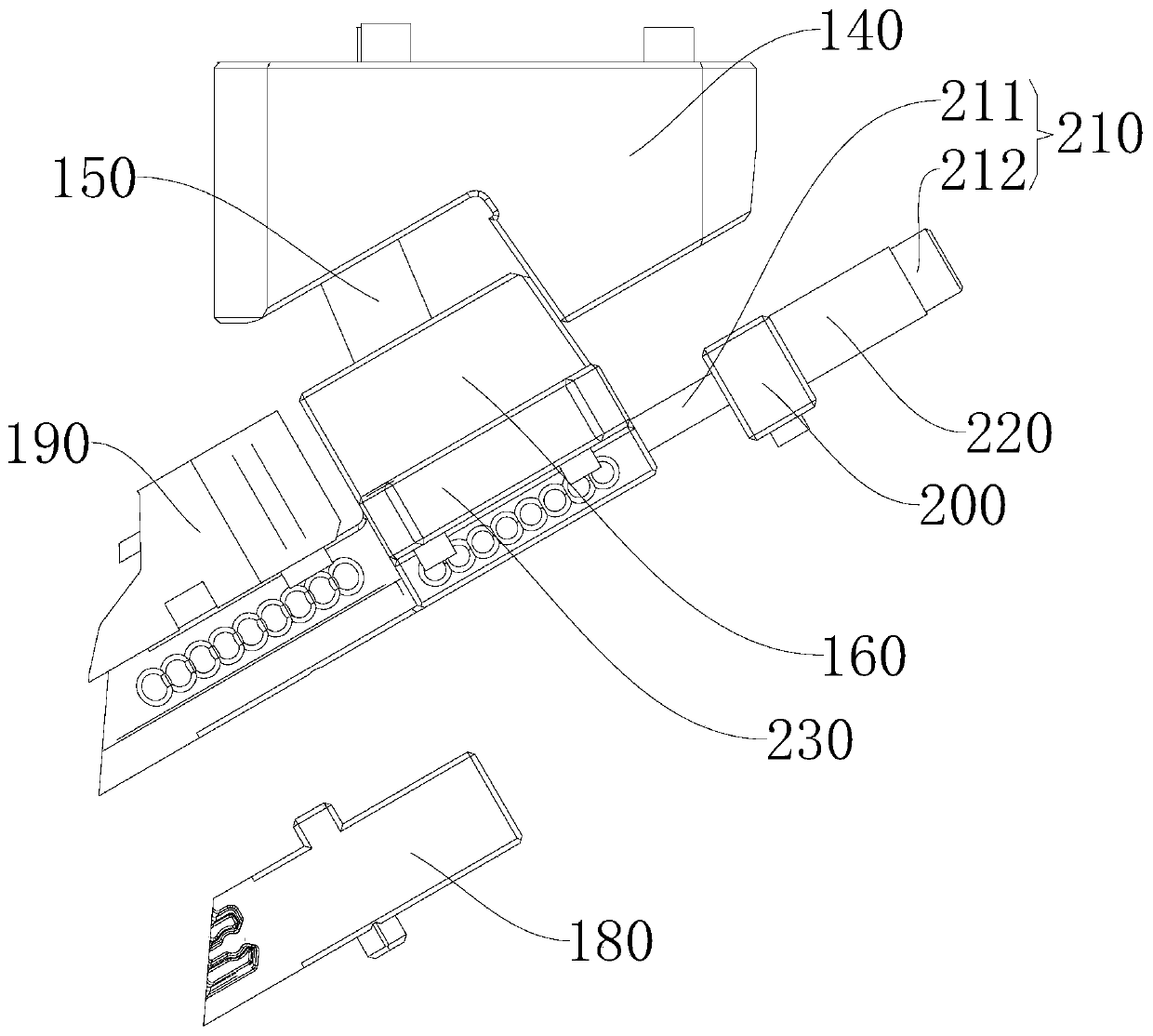

[0028] Please refer to figure 1 , figure 2 , image 3 and Figure 4 , the embodiment of the present invention provides a hybrid oblique drawing mechanism 100 for performing core-pulling molding on a product 300 . It can simplify the core-pulling structure, so that the core-pulling operation in two different directions is realized by the core-pulling power in the same direction, the processing and manufacturing are simple, the mold cost is reduced, and the occupied space is small. In this embodiment, the mixed oblique drawing mechanism 100 is used to pull the core of the buckle and screw column on the product 300, wherein the core pulling operation direction of the formed buckle is perpendicular to the core pulling operation direction of the formed screw column, and the mixed oblique drawing Mechanism 100 is capable of core pulling in both directions.

[0029] The mixing inclined pumping mechanism 100 includes a fixed platen 110, a movable platen 120, a hydraulic cylinder ...

no. 2 example

[0049] The invention provides an injection mold (not shown in the figure), which is used to manufacture plastic products. The injection mold includes a mixing inclined drawing mechanism 100, a fixed mold seat plate (not shown in the figure) and a movable mold seat plate (not shown in the figure). Wherein, the basic structure, principle and technical effect of the mixing inclined drawer mechanism 100 are the same as those of the first embodiment. For brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0050] In this embodiment, the fixed die base plate is connected with the fixed die plate 110, the movable die base plate is connected with the movable die plate 120, and the fixed die base plate and the movable die base plate are relatively arranged on both sides of the press (not shown in the figure). The movable mold base plate can be driven away from or close to the fixed mold base plate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com