Centering auxiliary device based on automobile oil cylinder support round hole drilling

A technology for oil cylinder supports and auxiliary devices, which is applied in the directions of positioning devices, supports, clamping, etc., can solve the problems of complex tooling structure, unreasonable structural design, rigid fixed tooling, etc., and achieve the advantages of improved flexibility and practicality and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

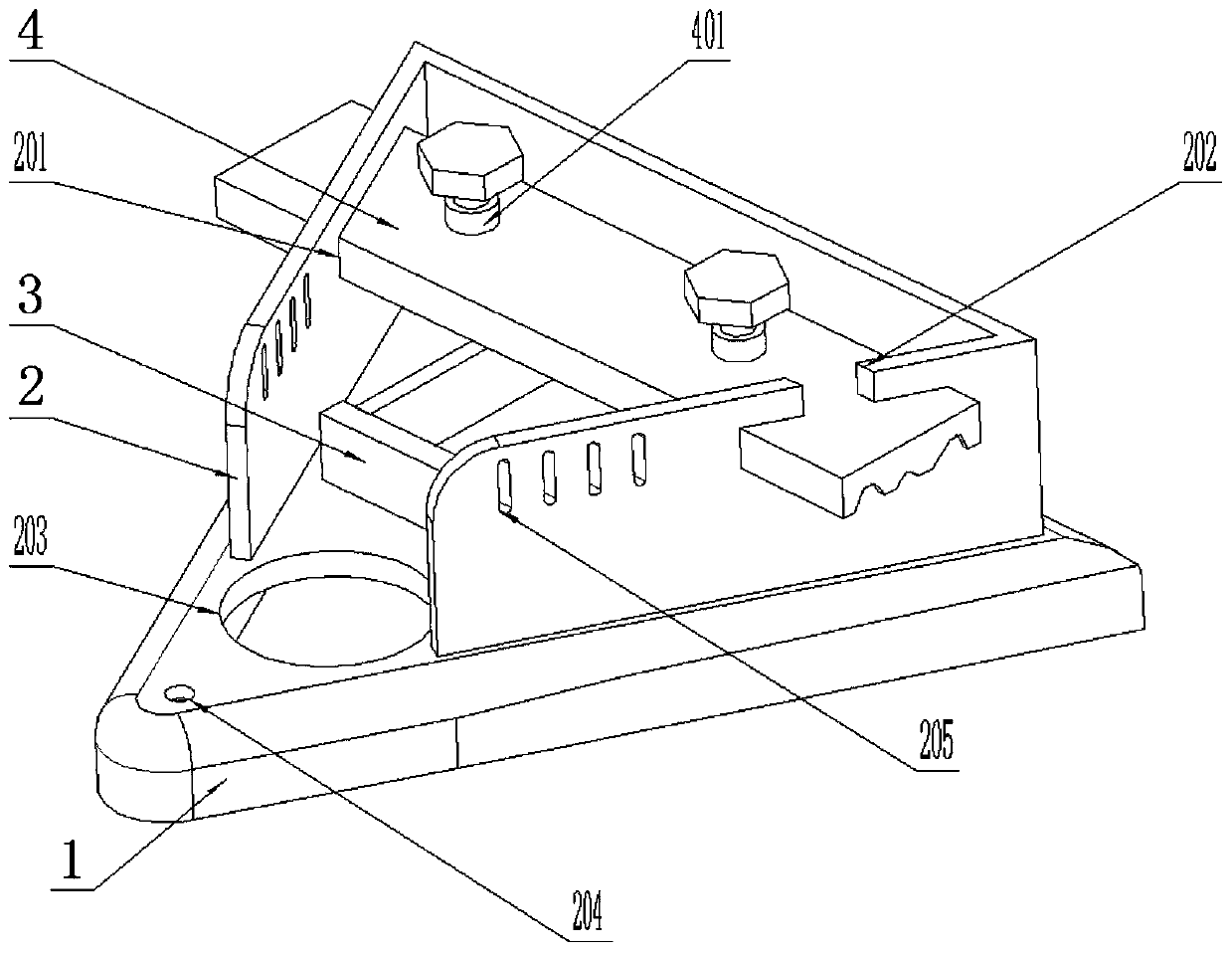

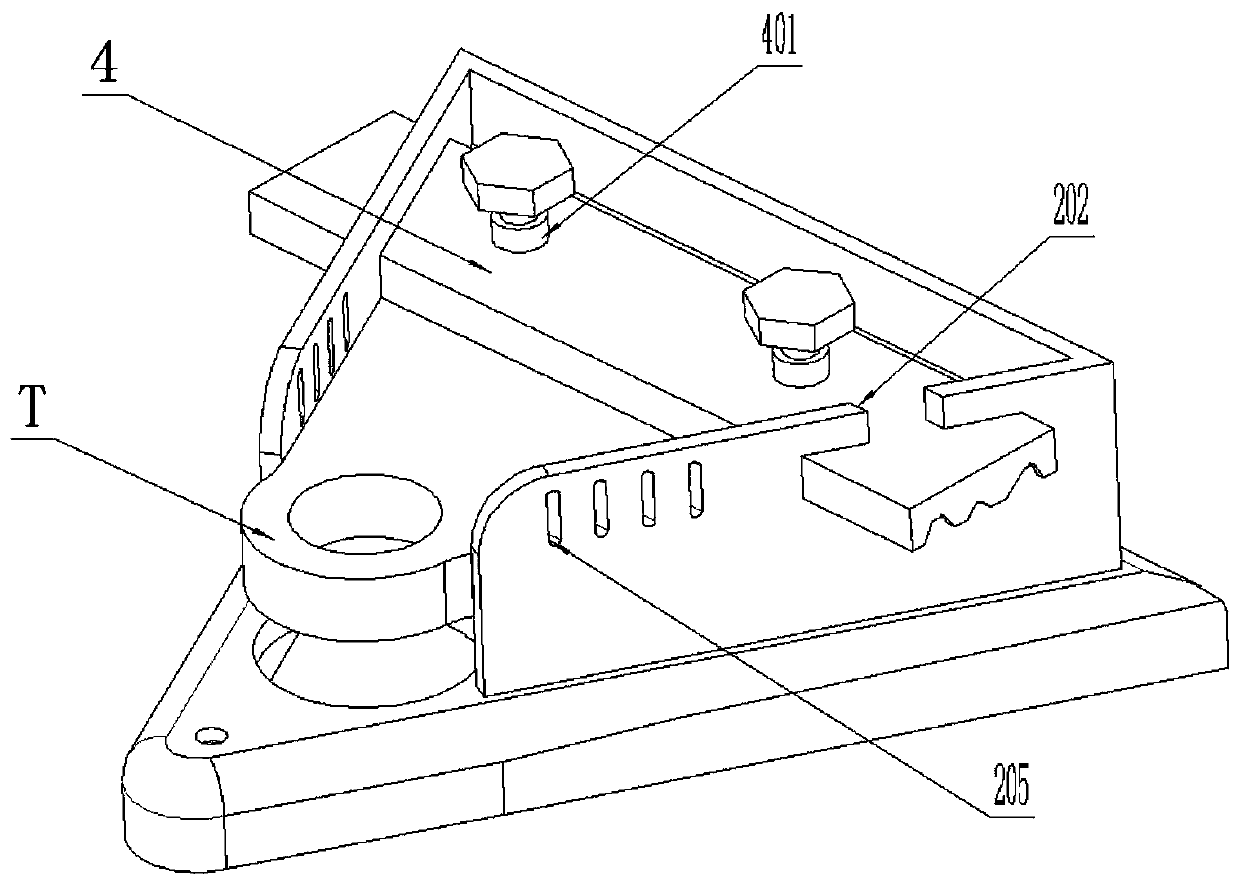

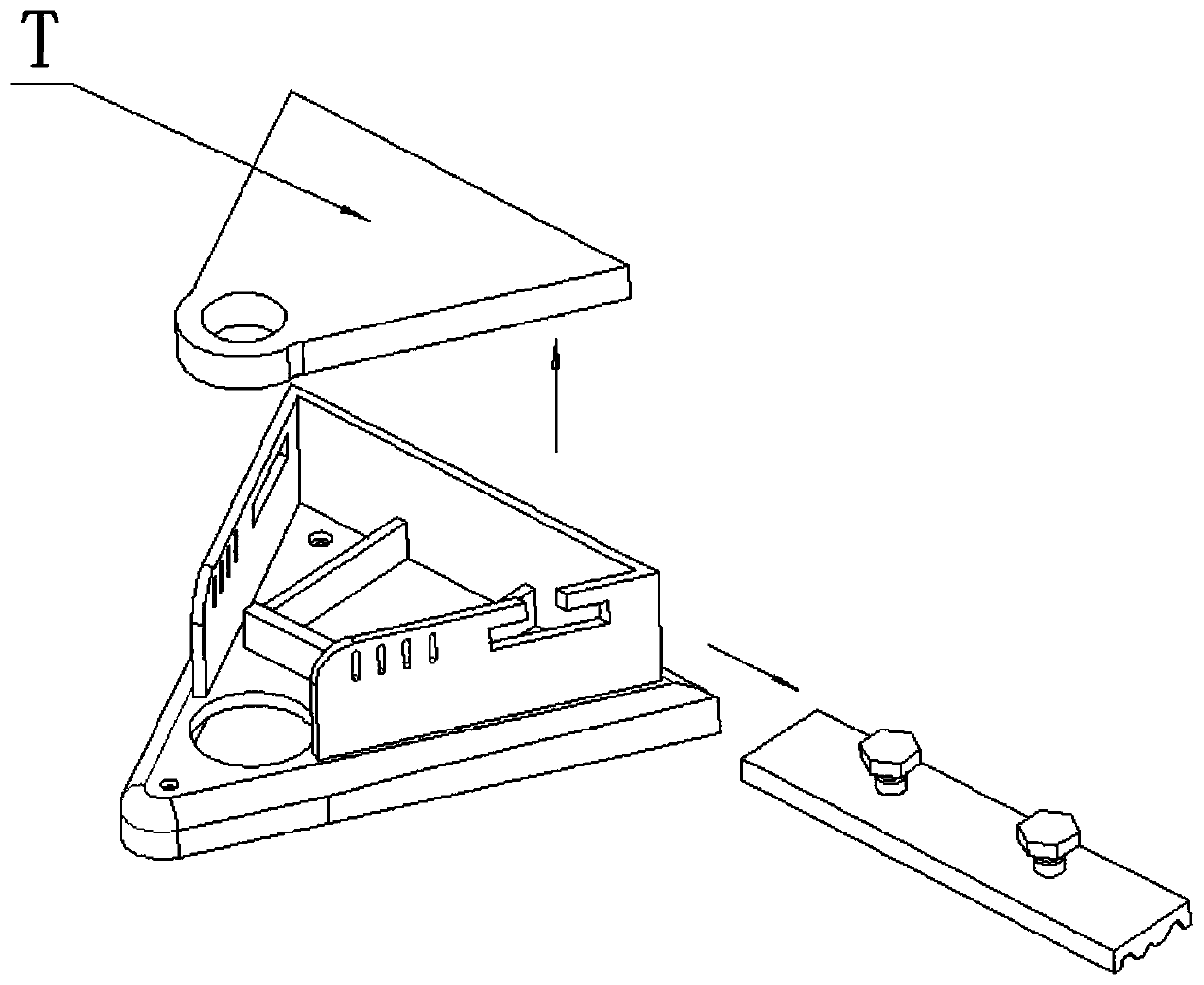

[0026] as attached figure 1 To attach Figure 5 Shown:

[0027] The invention provides a center alignment auxiliary device based on the round hole opening of the automobile oil cylinder support, which includes: a support cabin 1, a vertical cabin 2, a slot 201, a notch groove 202, a drill hole 203, a mounting hole 204, an overflow Groove 205, support frame 3, pressure seat 4, locking bolt 401, rubber block 402 and hand groove 403; the top surface of the brace 1 is welded with the vertical compartment 2, and welded at the middle position of the top surface of the brace 1 There is a support frame 3; the press seat 4 is a rectangular shell, its bottom surface is filled with a piece of rubber block 402, and the top surface of the press seat 4 is also provided with two circular through holes, and in these two through holes The positions are also welded with two threaded sleeves, and the threaded sleeves are all threaded with a locking bolt 401 of a stud structure style.

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com