A die-casting mold

A die-casting mold and master mold technology, applied in the field of die-casting molds, can solve problems such as uncontrollable pouring of juice, long product repair time, and difficult metal separation, so as to reduce process time, save product follow-up processing process time, and improve injection molding. The effect of material speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

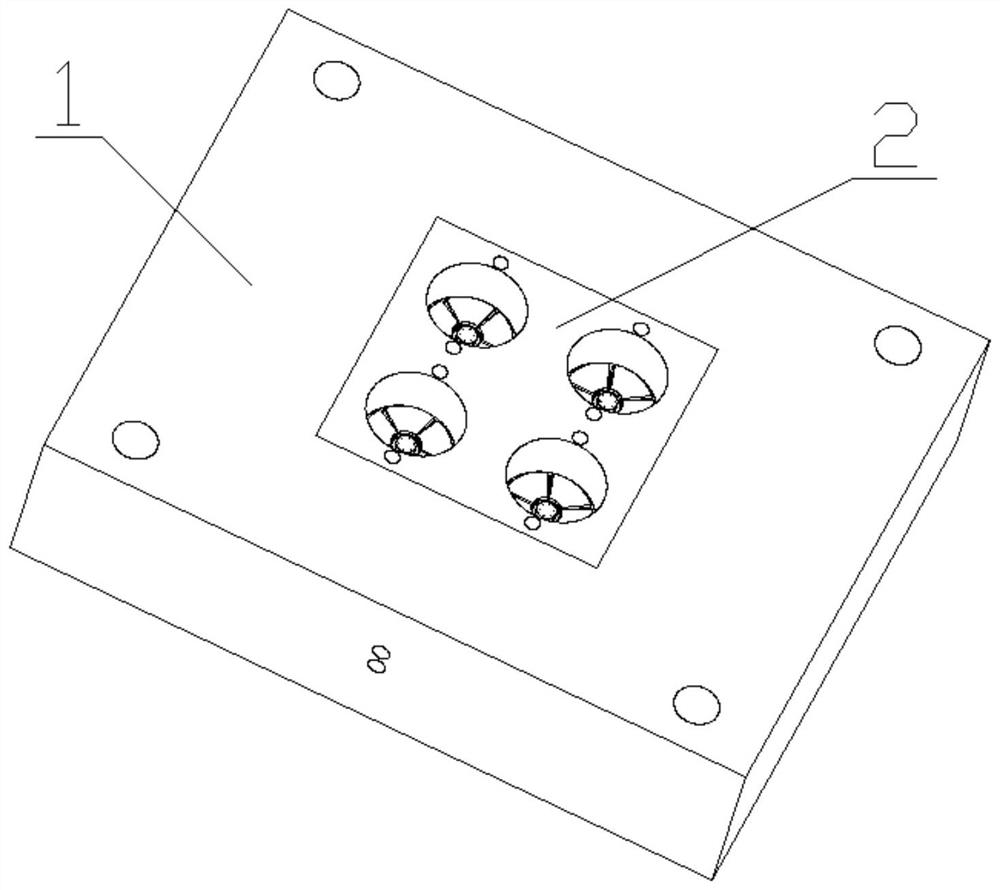

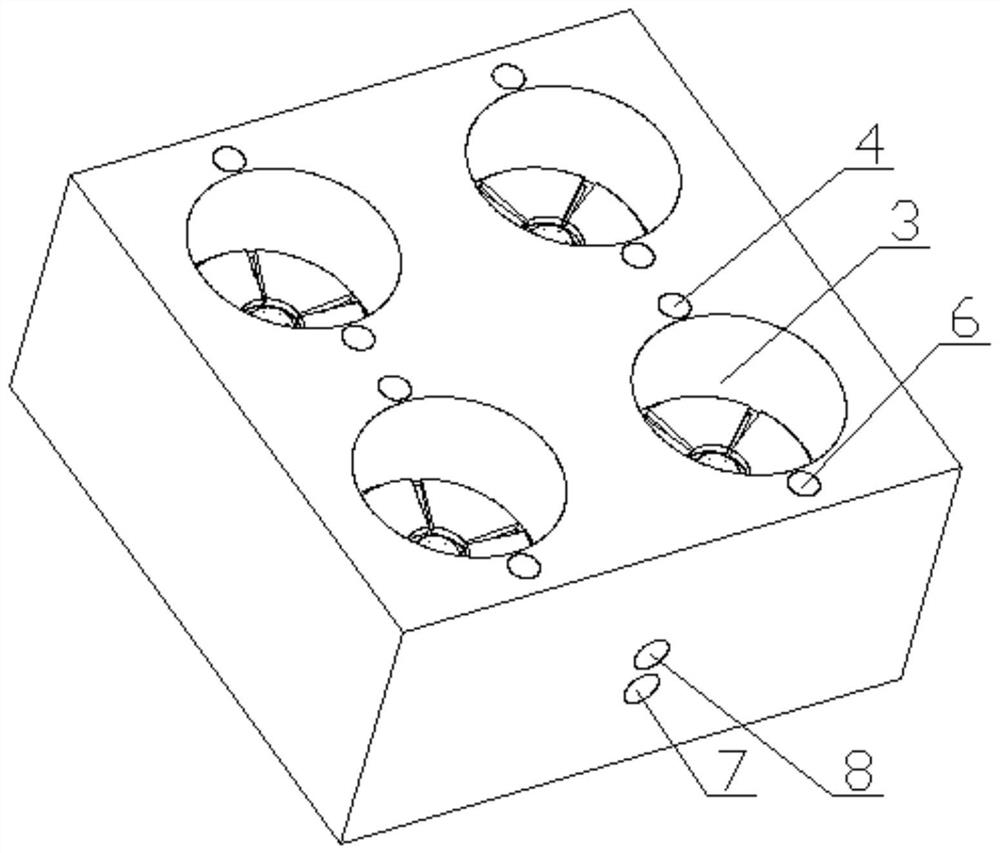

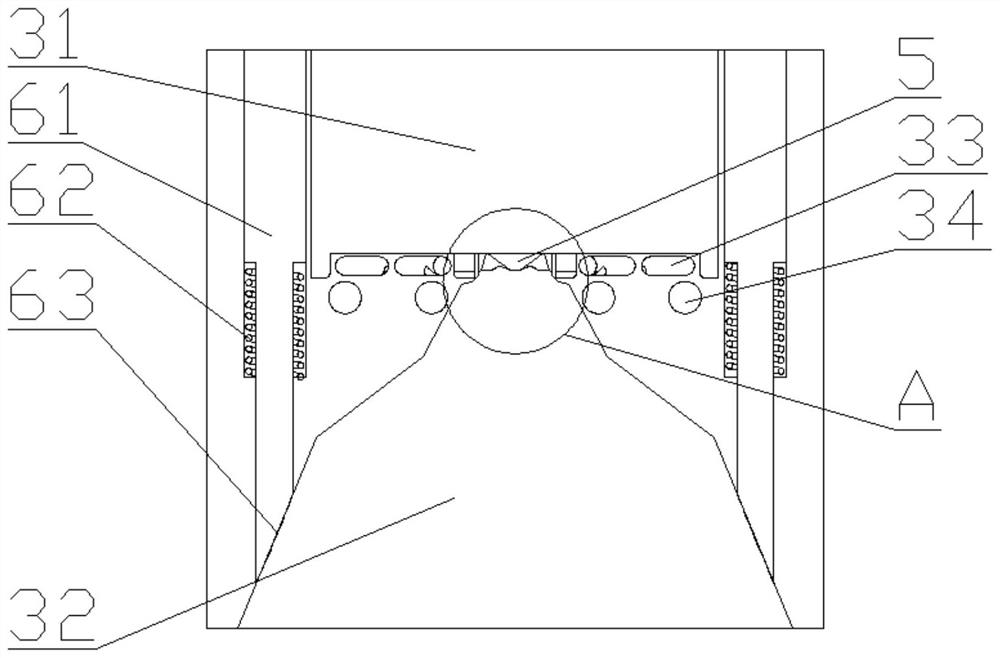

[0024] Such as figure 1 Shown; A kind of die-casting mold, comprises master template 1, is provided with master mold groove, liquid outlet hole and liquid inlet hole in described master template 1, is provided with master mold 2 in described master mold groove, and described master mold 2 is provided with a cooling liquid inlet hole 7 and a cooling liquid outlet hole 8, the cooling liquid inlet hole 7 and the cooling liquid outlet hole 8 are connected with the liquid outlet hole and the liquid inlet hole respectively, and the mother mold 2 is provided with There are several product forming mechanisms 3, one side of the product forming mechanism 3 is provided with a positioning demoulding hole 4, the positioning demoulding hole 4 is provided with a tailing separation mechanism 6, and the working end of the tailing separation mechanism 6 is connected to the The product forming mechanism 3 cooperates, and the cooling liquid inlet hole 7 and the cooling liquid outlet hole 8 are re...

Embodiment 2

[0027] On the basis of Embodiment 1, the top point of the tapered cavity 51 is a vertical line perpendicular to the mother template 1, and the vertical line forms a maximum angle C with one side of the tapered cavity 51, and the vertical line and the cone The other side of the cavity 51 forms a minimum angle B, the degree of the angle C is 20 degrees to 70 degrees, and the degree of the angle B is 1 / 4 to 4 / 3 of the angle C; The degree of the angle C is 45 degrees to 55 degrees, and the degree of the angle B is 1 / 2 of the angle C; the injection hole 52 is elliptical, and the length of the ellipse is 0.3mm to 1.0mm; The injection mold cavity 32 is conical; the plurality of conical cavities 51 are arranged in a circle, and the sides of the largest angle C of the conical cavities 51 are arranged toward the center of the conical cavities 51 arranged in a circle; The mother mold 2 is provided with an exhaust groove for exhausting the molding cavity 31; one end of the injection ring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com