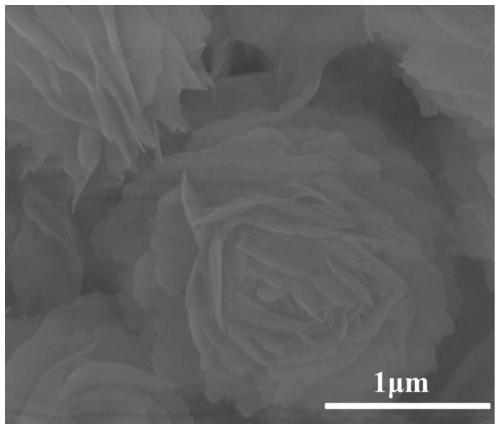

Preparation method of earthy yellow (BiO)2CO3 multistage structure microsphere

A khaki, microsphere technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of single function, narrow spectral response range, low photocatalytic efficiency, etc. The effect of high photocatalytic activity, easy material transport, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

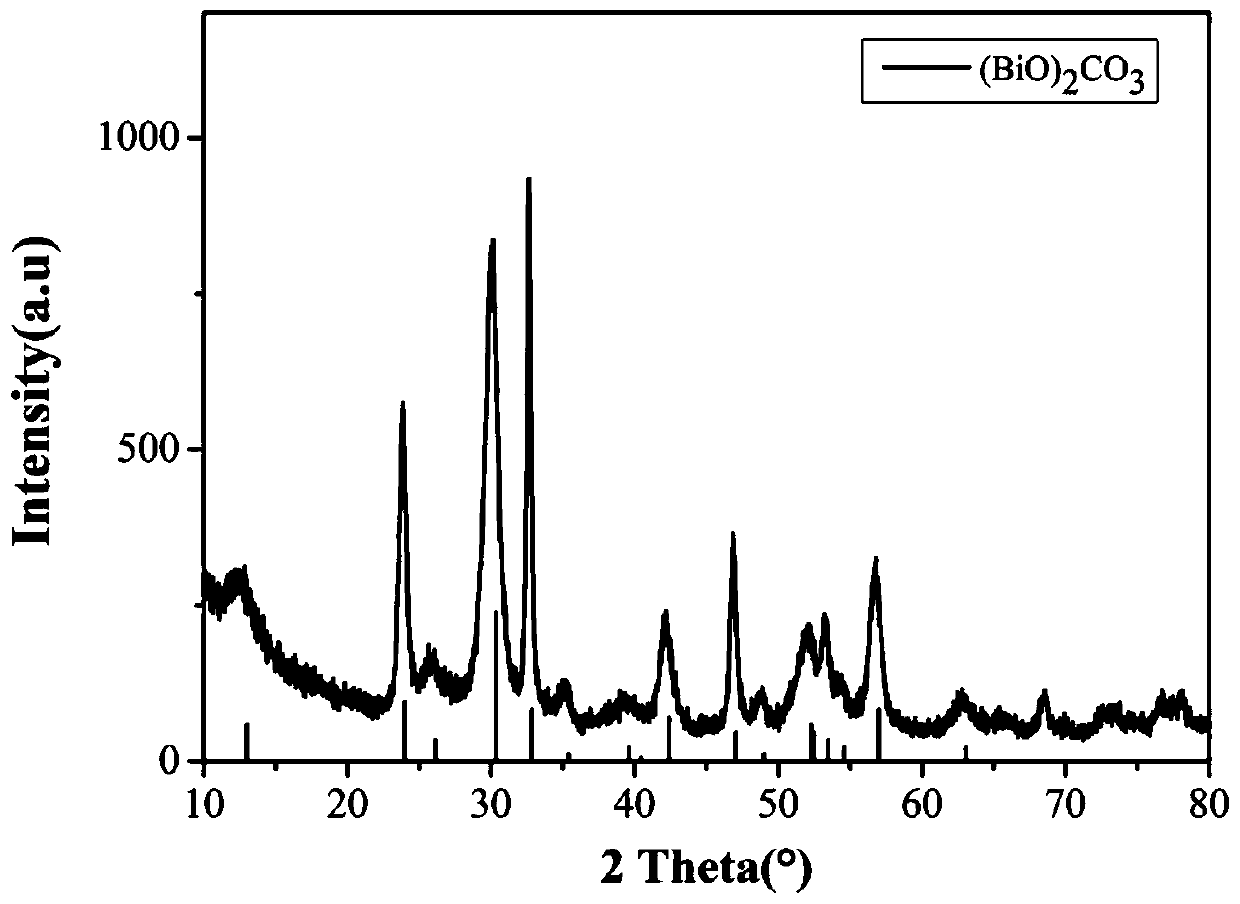

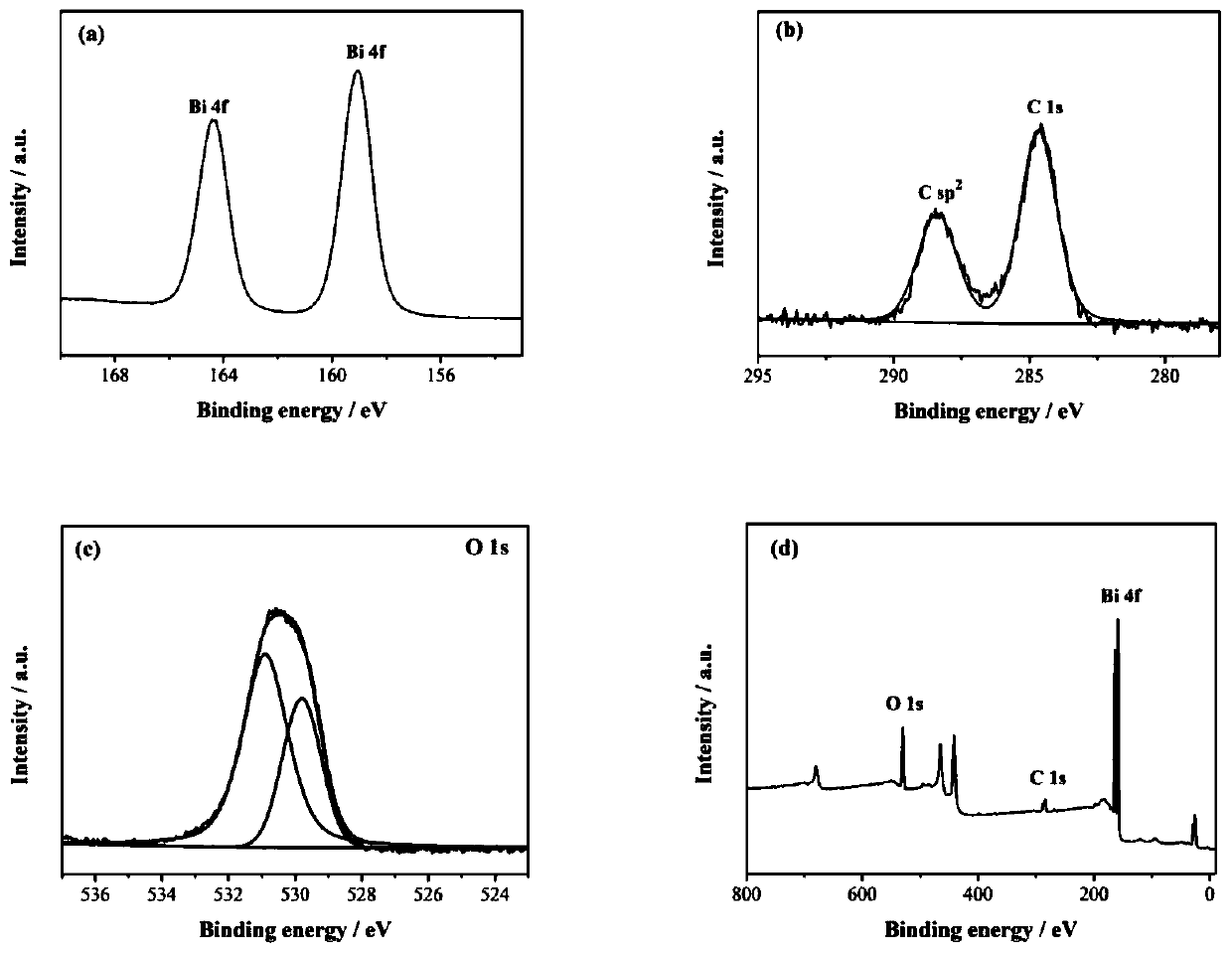

[0029] This embodiment provides a kind of khaki (BiO) 2 CO 3 The preparation method of hierarchical microspheres comprises the steps of:

[0030] S1. Wash the reaction kettle in nitric acid solution, sodium hydroxide solution and aqueous solution respectively at 180°C, 140°C and 120°C for 2 hours and then dry it for later use;

[0031] S2. Put magnets in the reaction kettle, add ultrapure water and sodium citrate dihydrate into the reaction kettle, mix and stir for 10 minutes; take 25mL ultrapure water for every 1mmol of sodium citrate dihydrate;

[0032] In the present embodiment, the amount of sodium citrate dihydrate is 1 mmol, and the amount of ultrapure water is 25 mL.

[0033] S3, add Bi(NO in the reactor of step S2 3 ) 3 ·5H 2 0, making the mol ratio of sodium citrate dihydrate and bismuth nitrate pentahydrate be 2:1, and continue to stir for 1 hour to obtain mixed solution;

[0034] In this example, the amount of bismuth nitrate pentahydrate was 0.5 mmol.

[003...

Embodiment 2

[0045] This embodiment aims at understanding the khaki (BiO) obtained by the preparation method described in Example 1 by providing an experiment 2 CO 3 Environmental Purification Activity of Hierarchical Microspheres.

[0046] Take a certain amount of khaki (BiO) 2 CO 3 A multi-level structure microsphere powder catalyst, and take a certain amount of cadmium sulfate of different qualities and dissolve it in a certain amount of water. The two are mixed and adsorbed for a certain period of time, and the concentration of the material before and after the adsorption of Cd is detected by an inductively coupled plasma emission spectrometer. The adsorption capacity of the material to Cd, the adsorption capacity obtained by the test is as follows Figure 7 Shown, the maximum adsorption capacity of product by Freundlich and Langmuir adsorption curve fitting is 1115.7mg / g. At the same time, fix a certain concentration of cadmium sulfate and add the same mass of khaki (BiO) 2 CO 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com