An autonomous inspection method for large storage tanks based on quadrotor drones

A technology of quadrotor UAV and large storage tank, which is applied in the directions of instruments, three-dimensional position/channel control, control/regulation system, etc., and can solve the problem of autonomous inspection, low detection efficiency and detection cost of quadrotor UAV. High-level problems, to achieve the effect of eliminating potential safety hazards, low detection cost, and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0165] An autonomous inspection method for large storage tanks based on quadrotor drones. The geometric parameters of the large storage tank described in this embodiment:

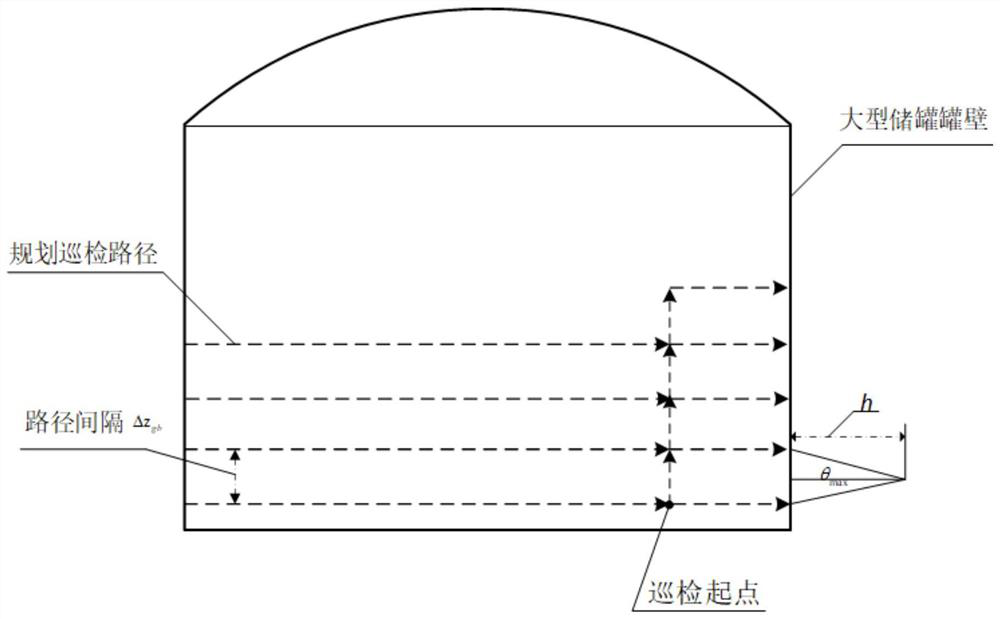

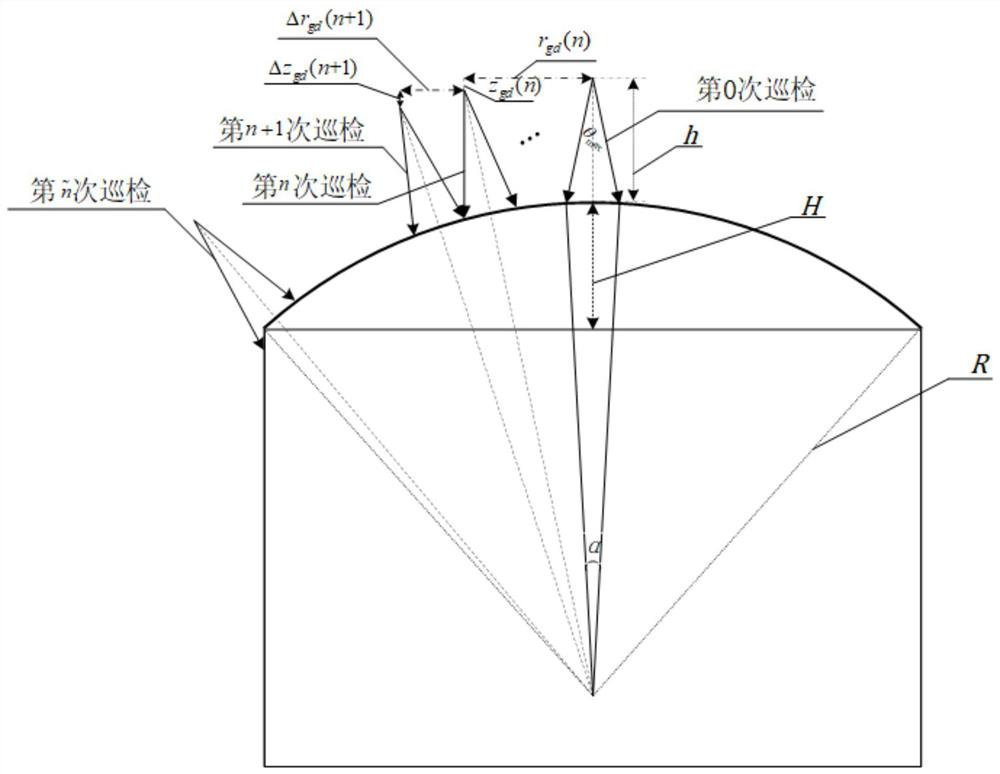

[0166] The large storage tanks such as figure 1 As shown, the shape of the large storage tank body is a cylinder, and the shape of the filling of the large storage tank is a spherical body. The large storage tank: the diameter of the tank body is 30m, the height of the tank body is 14m, the radius of the spherical surface of the filling roof is R=17.32m, and the height of the curved surface of the tank top is H=8.66m.

[0167] The tank wall of the large storage tank has no obstacles.

[0168] This embodiment is an autonomous inspection method for an obstacle-free flight area on the wall of a large storage tank based on a quadrotor UAV. The steps of the autonomous inspection method are:

[0169] Step 1. Autonomous inspection system based on quadrotor UAV

[0170] The autonomous inspection system based on...

Embodiment 2

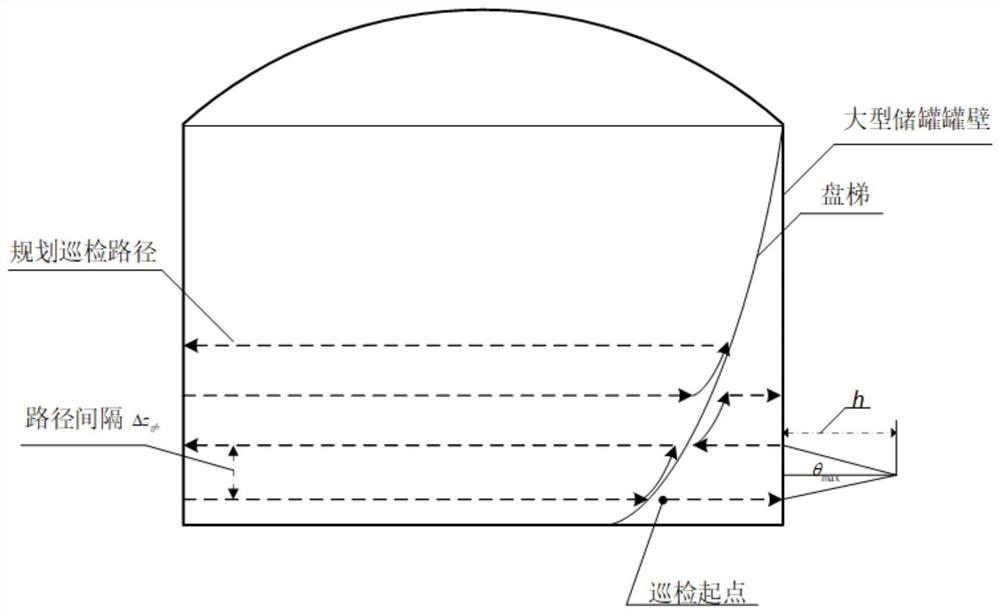

[0315] An autonomous inspection method for large storage tanks based on quadrotor drones. The geometric parameters of the large storage tank described in this embodiment:

[0316] The large storage tanks such as figure 2 As shown, the shape of the large storage tank body is a cylinder, and the shape of the filling of the large storage tank is a spherical body. The large storage tank: the diameter of the tank body is 30m, the height of the tank body is 14m, the radius of the spherical surface of the filling roof is R=17.32m, and the height of the curved surface of the tank top is H=8.66m.

[0317] There is an obstruction on the wall of the large storage tank.

[0318] This embodiment is an autonomous inspection method for an obstacle-free flight area on the wall of a large storage tank based on a quadrotor UAV. The steps of the autonomous inspection method are:

[0319] Step 1. Autonomous inspection system based on quadrotor UAV

[0320] The autonomous inspection system ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com