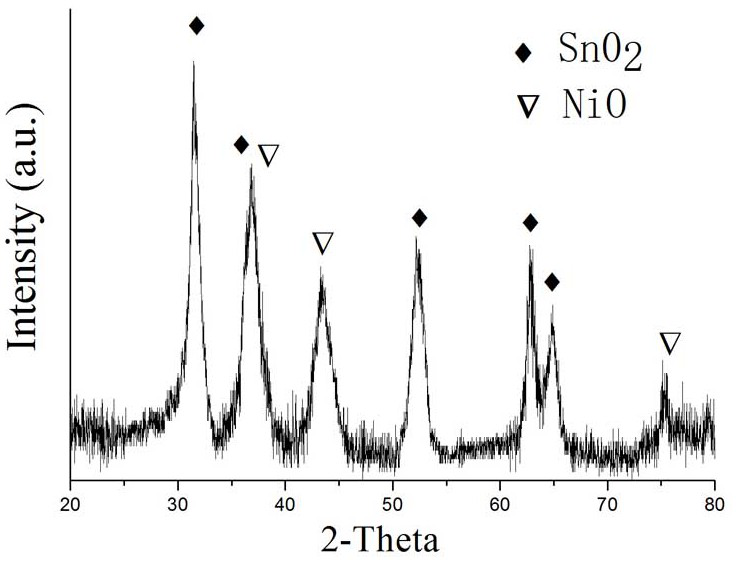

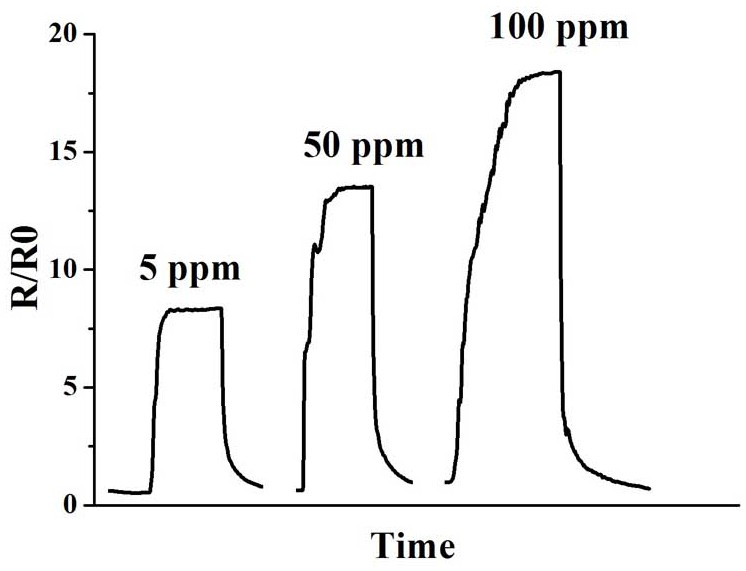

A kind of n-p heterogeneous core-shell array gas-sensing material and its preparation method

A gas-sensitive material, n-p technology, applied in the direction of material resistance, etc., can solve the problems of interface electron depletion, reduce the gas sensitivity of materials, shorten the service life of gas-sensitive materials, etc., and achieve the effect of strong selectivity and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The steps are:

[0025] Step 1: Porous alumina template preparation

[0026] Select an aluminum oxide template with a pore size of 200nm and double-pass, magnetron sputtering a layer of gold film with a thickness of 0.5μm on the back of it, and then after ultrasonic cleaning with trimethylsilyl cyanide, ethanol, and distilled water, dry it for later use;

[0027] The second step: Sn nanotube array preparation

[0028] Sn nanotube arrays were prepared by pulse electrodeposition in the electrolytic cell: the alumina template was prepared in the first step as the working electrode, the tin sheet was used as the counter electrode, and the tin wire was used as the auxiliary electrode. Pulse electrodeposition was performed after adding the deposition solution. After completion, wash with distilled water until neutral, and heat-treat at 200°C for 1 hour;

[0029] The composition of the deposition solution is: 0.1mol / L SnCl 4 ·5H 2 O, 0.01 mol / L NaCl, H 3 BO 3 and Na 3 C...

Embodiment 2

[0038] The steps are:

[0039] Step 1: Porous alumina template preparation

[0040] Select an aluminum oxide template with a pore size of 200nm and double-pass, magnetron sputtering a layer of gold film with a thickness of 0.5μm on the back of it, and then after ultrasonic cleaning with trimethylsilyl cyanide, ethanol, and distilled water, dry it for later use;

[0041] The second step: Sn nanotube array preparation

[0042] Sn nanotube arrays were prepared by pulse electrodeposition in the electrolytic cell: the alumina template was prepared in the first step as the working electrode, the tin sheet was used as the counter electrode, and the tin wire was used as the auxiliary electrode. Pulse electrodeposition was performed after adding the deposition solution. After completion, wash with distilled water until neutral, and heat-treat at 120°C for 5 hours;

[0043] The composition of the deposition solution is: 0.1mol / L SnCl 4 ·5H 2 O, 0.01 mol / L NaCl, H 3 BO 3 and Na 3 ...

Embodiment 3

[0052] The steps are:

[0053] Step 1: Porous alumina template preparation

[0054] Select an aluminum oxide template with a pore size of 200nm and double-pass, magnetron sputtering a layer of gold film with a thickness of 0.5μm on the back of it, and then after ultrasonic cleaning with trimethylsilyl cyanide, ethanol, and distilled water, dry it for later use;

[0055] The second step: Sn nanotube array preparation

[0056] Sn nanotube arrays were prepared by pulse electrodeposition in the electrolytic cell: the alumina template was prepared in the first step as the working electrode, the tin sheet was used as the counter electrode, and the tin wire was used as the auxiliary electrode. Pulse electrodeposition was performed after adding the deposition solution. After completion, wash with distilled water until neutral, and heat-treat at 150°C for 3 hours;

[0057] The composition of the deposition solution is: 0.1mol / L SnCl 4 ·5H 2 O, 0.01 mol / L NaCl, H 3 BO 3 and Na 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com