Automatic drying device for special polyester knitted fabric processing

A technology for drying equipment and knitted fabrics, applied in lighting and heating equipment, drying, drying machines and other directions, can solve the problems of poor drying effect, waste a lot of time, low drying efficiency, etc., to improve drying Effect and drying efficiency, energy saving, high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

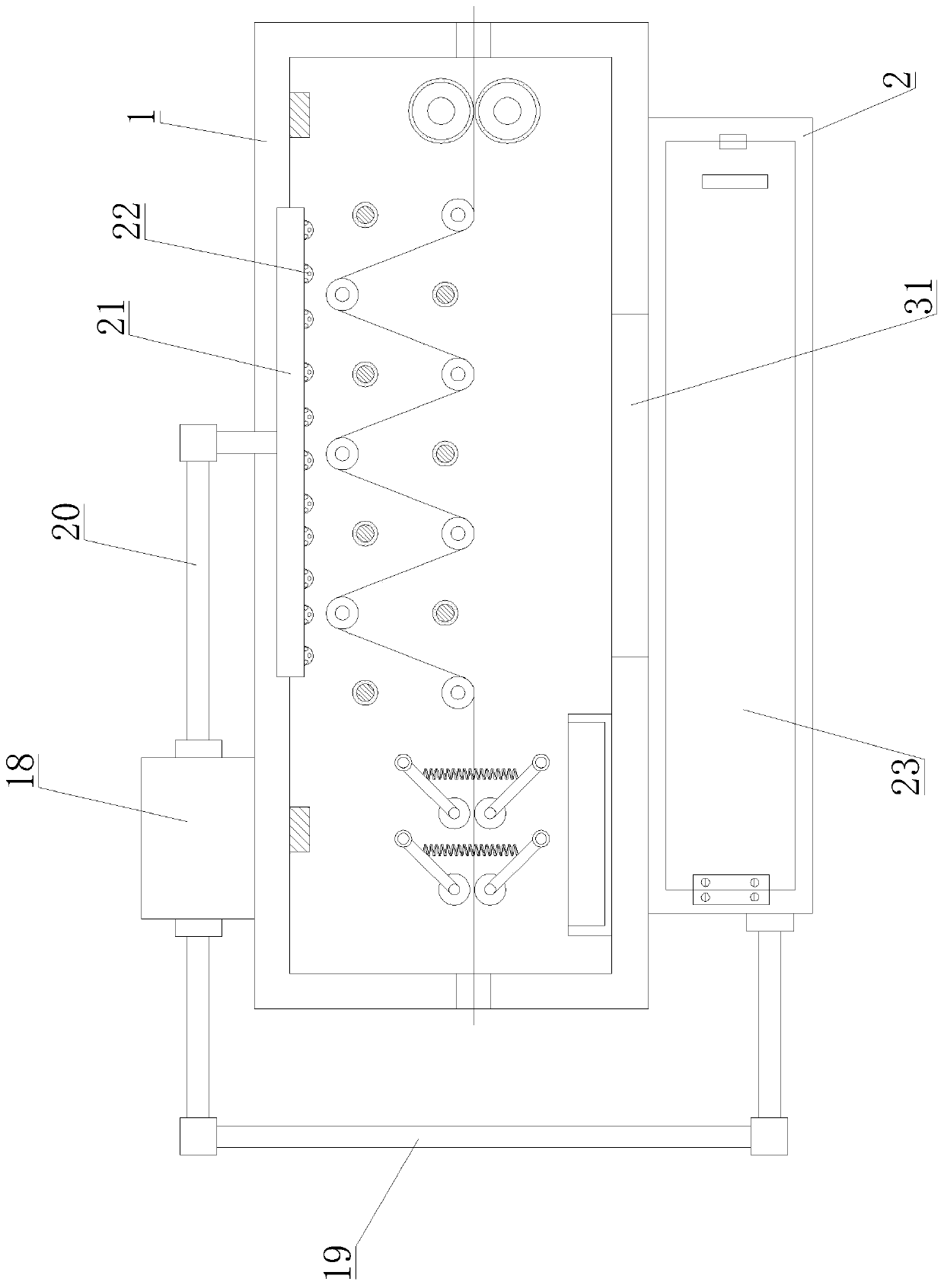

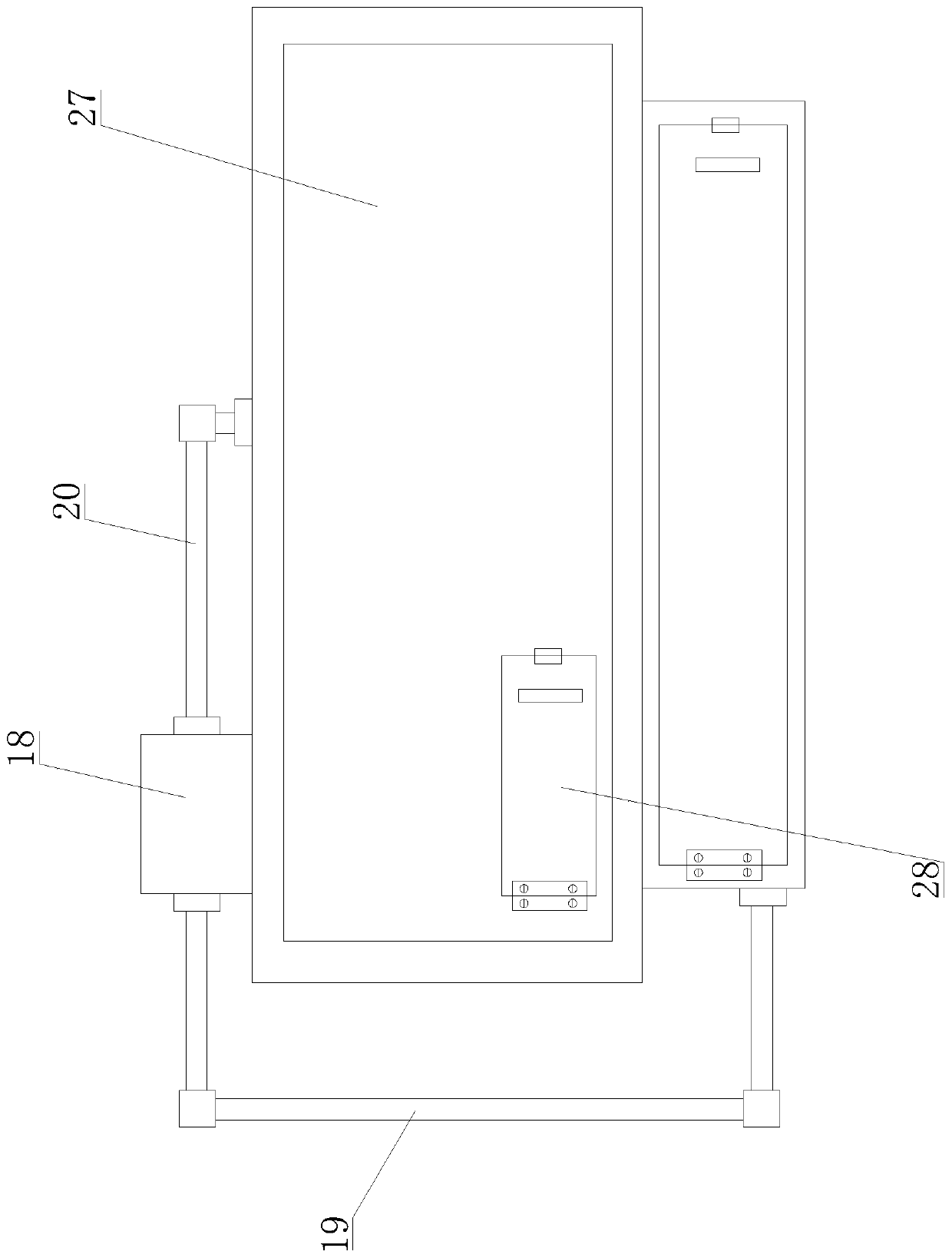

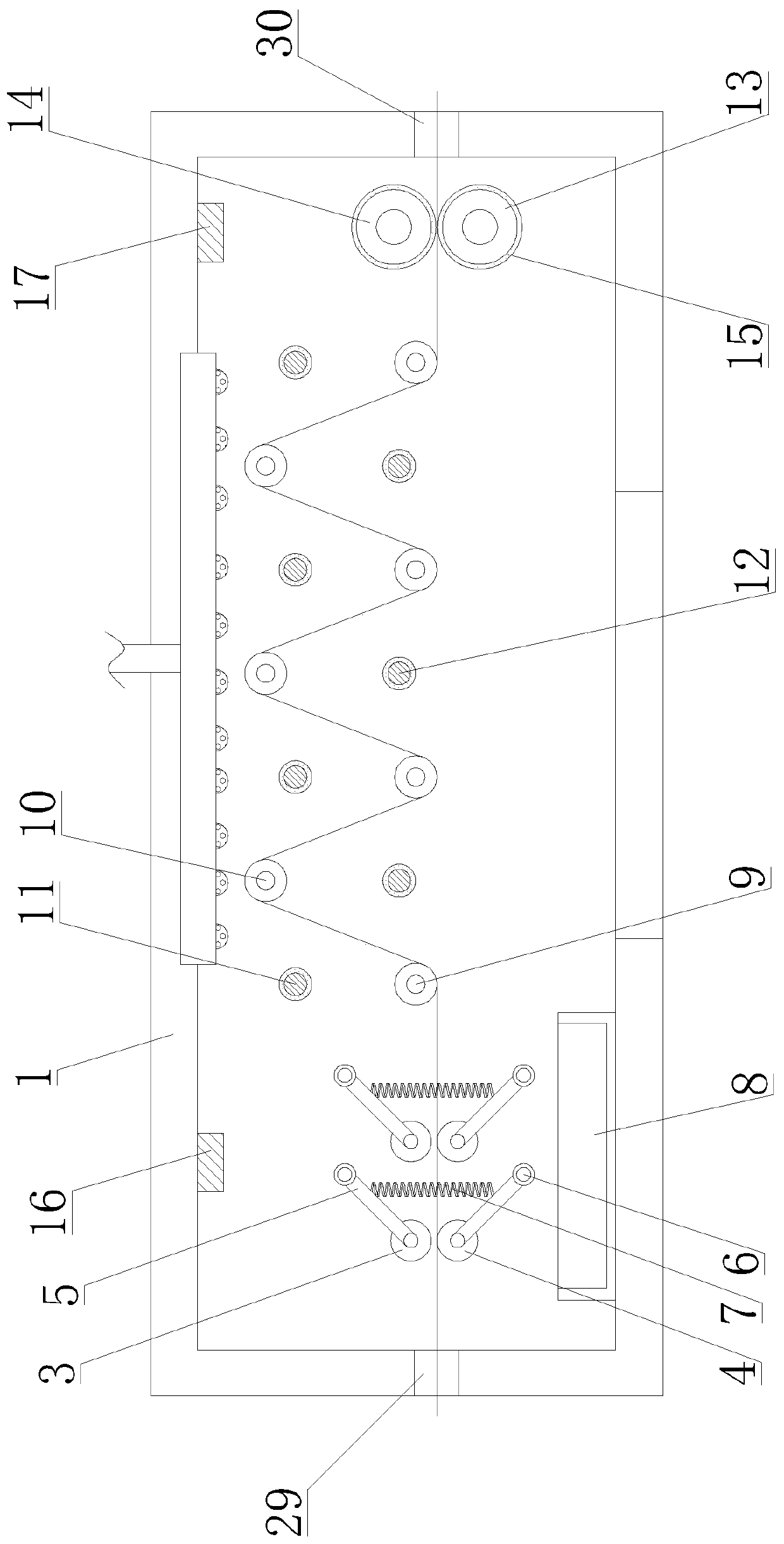

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0033] refer to figure 1 , a special automatic drying equipment for polyester knitted fabric processing, including drying box 1, dehumidification box 2, first guide roller 9, second guide roller 10, first heating element 11, second heating element 12, pumping An air machine 18, an input pipe 19, an output pipe 20, a connector 21 and a water squeezing assembly, and the drying box 1 is provided with an input port 29 and an output port 30;

[0034] The water squeeze assembly is located in the drying box 1 and is in a position close to the input port. The number of the water squeeze assemblies is multiple groups and arranged at equal distances in the transverse direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com