A Smart Control Method for Sewage Plants Based on Catastrophic Inversion Water Production Prediction Model

A technology for prediction model and inversion model, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Accuracy, simplification of the solution process, and the effect of solving time-delay problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The functions and real-time methods of the present invention are described below through specific embodiments. The embodiment is only one of the implementation methods of the present invention, not all of them. It should be understood that all application embodiments based on the present invention shall fall within the protection scope of the present invention.

[0048] The invention provides an intelligent control method of a sewage plant based on a catastrophic inversion water production prediction model, which realizes the automatic control of the machine, and the effluent water quality is stable and reaches the standard.

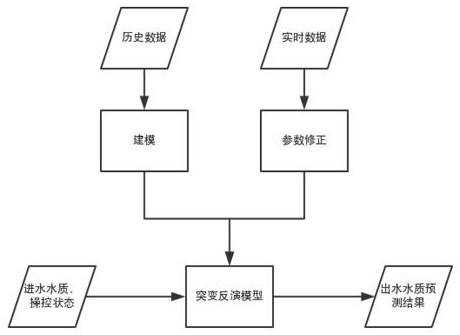

[0049] The implementation method of the present invention is as figure 1 Shown: Preprocess the data collected by the equipment through the intelligent perception module, input the catastrophic inversion model to predict the water quality parameters, input the predicted water quality parameters into the intelligent control module, and obtain the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com