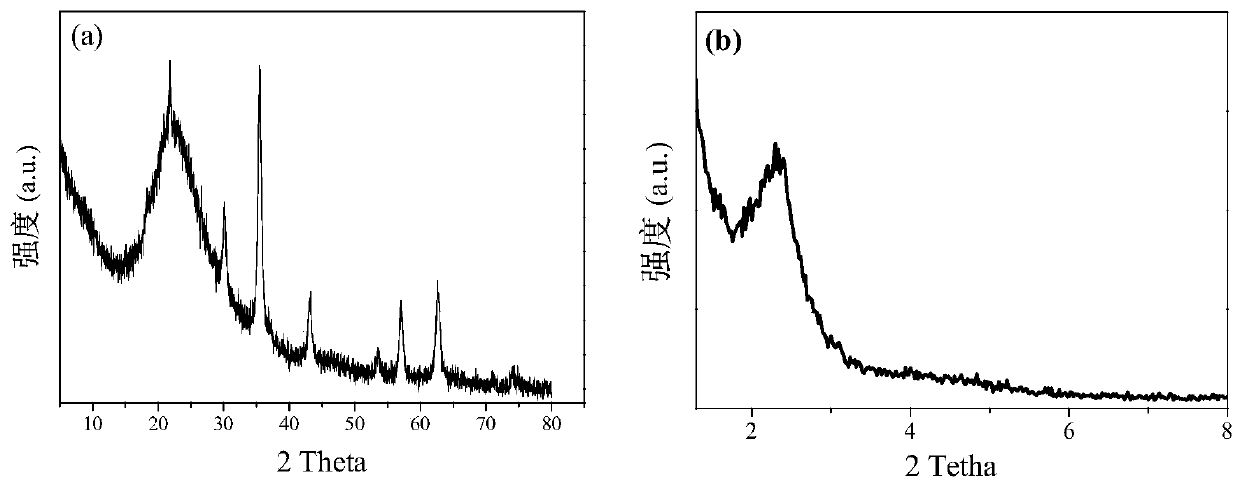

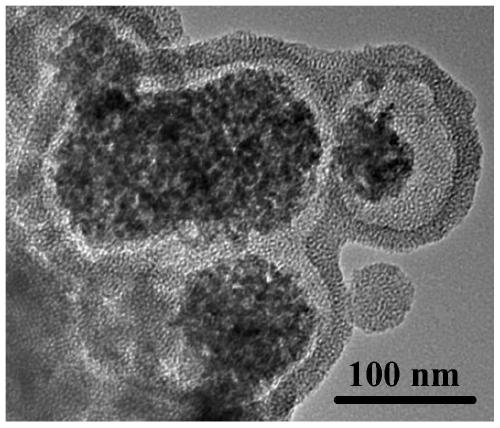

Method for preparing magnetic mesoporous silica composite nanoparticles of yolk-eggshell structure

A technology of mesoporous silica and composite nanoparticles, applied in the directions of silica, silicon oxide, ferrous oxide, etc., can solve the problems of complex process, high synthesis cost, and inability to effectively control structural parameters, etc. Achieve the effect of easy availability of raw materials, high specific surface area, and adjustable cavity size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the magnetic mesoporous silica composite nanoparticles of egg yolk-eggshell structure in this example is as follows:

[0028] Step 1, the average particle diameter is the magnetic Fe of 80nm 3 o 4 Put 0.050g of nanoparticles in a three-necked flask, add 25mL of deionized water and 50mL of absolute ethanol, and ultrasonically disperse for 10min to obtain Fe 3 o 4 Dispersions;

[0029] Step 2, in Fe 3 o 4 In the dispersion liquid, add 0.2003g resorcinol and 1.83mL formaldehyde solution with a mass concentration of 37% while stirring, and then add ammonia water with a mass concentration of 25% to adjust the pH to 9-10, and the obtained system A is reacted at 25°C 24h; after the reaction, centrifuged, washed with absolute ethanol for 3 times, and vacuum-dried at 70°C for 12h to obtain the phenolic resin-wrapped Fe 3 o 4 Nanoparticles, labeled RF@Fe 3 o 4 Nanoparticles;

[0030] Step 3. Put RF@Fe 3 o 4 Put 0.05g of nanoparticles in a thr...

Embodiment 2

[0033] In this example, magnetic mesoporous silica composite nanoparticles with egg yolk-eggshell structure were prepared according to the same method as in Example 1, the only difference being that the dosages of resorcinol and formaldehyde solutions in step 2 were 0.2507g and 2.29mL respectively .

Embodiment 3

[0035] In this example, magnetic mesoporous silica composite nanoparticles with egg yolk-eggshell structure were prepared according to the same method as in Example 1, the only difference being that the dosages of resorcinol and formaldehyde solutions in step 2 were 0.4190 g and 4.60 mL, respectively. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com