Insert type demolding mechanism

A technology of demoulding mechanism and insert, which is applied in the field of block-type demoulding mechanism, can solve the problems of difficult demoulding of thin-walled deep-cavity plastic parts, difficult processing of forming molds, and unguaranteed quality, so as to improve the demoulding effect and process Easy to manufacture and improve the quality of injection molded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

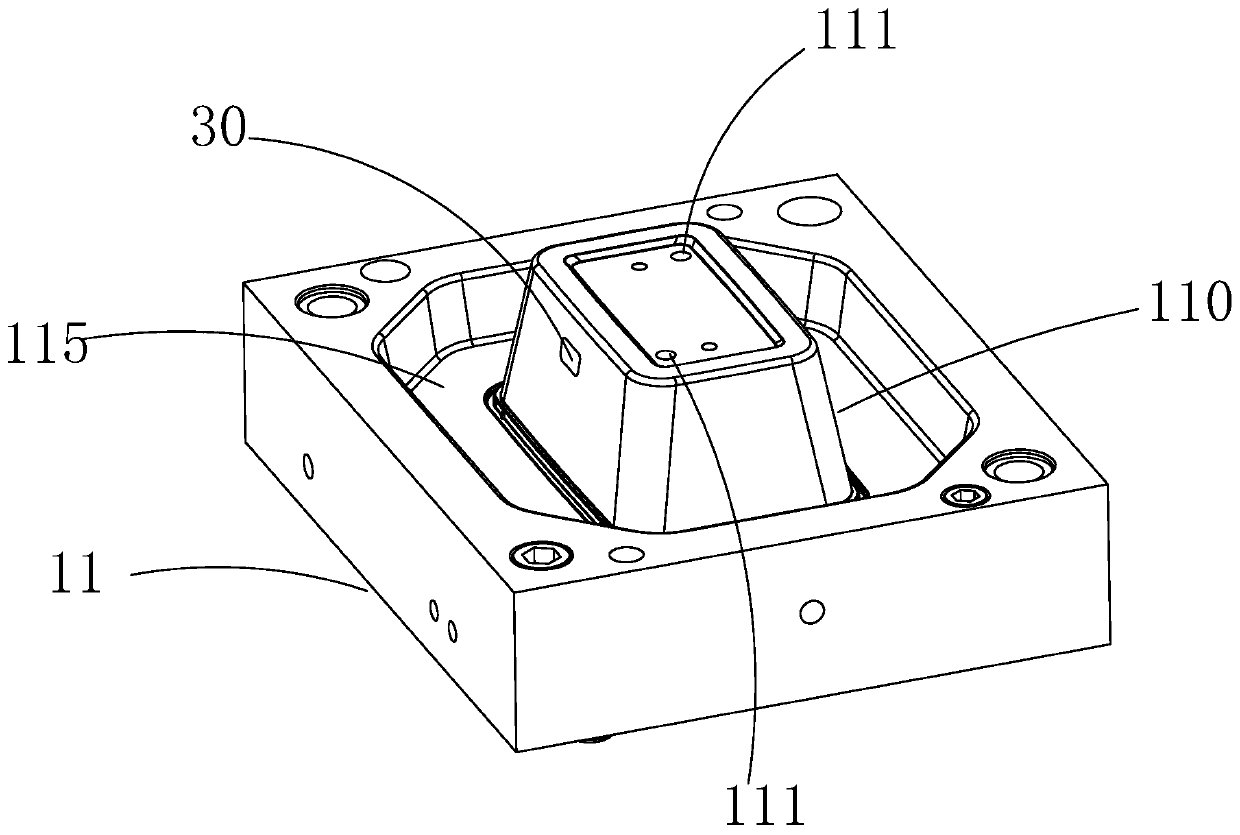

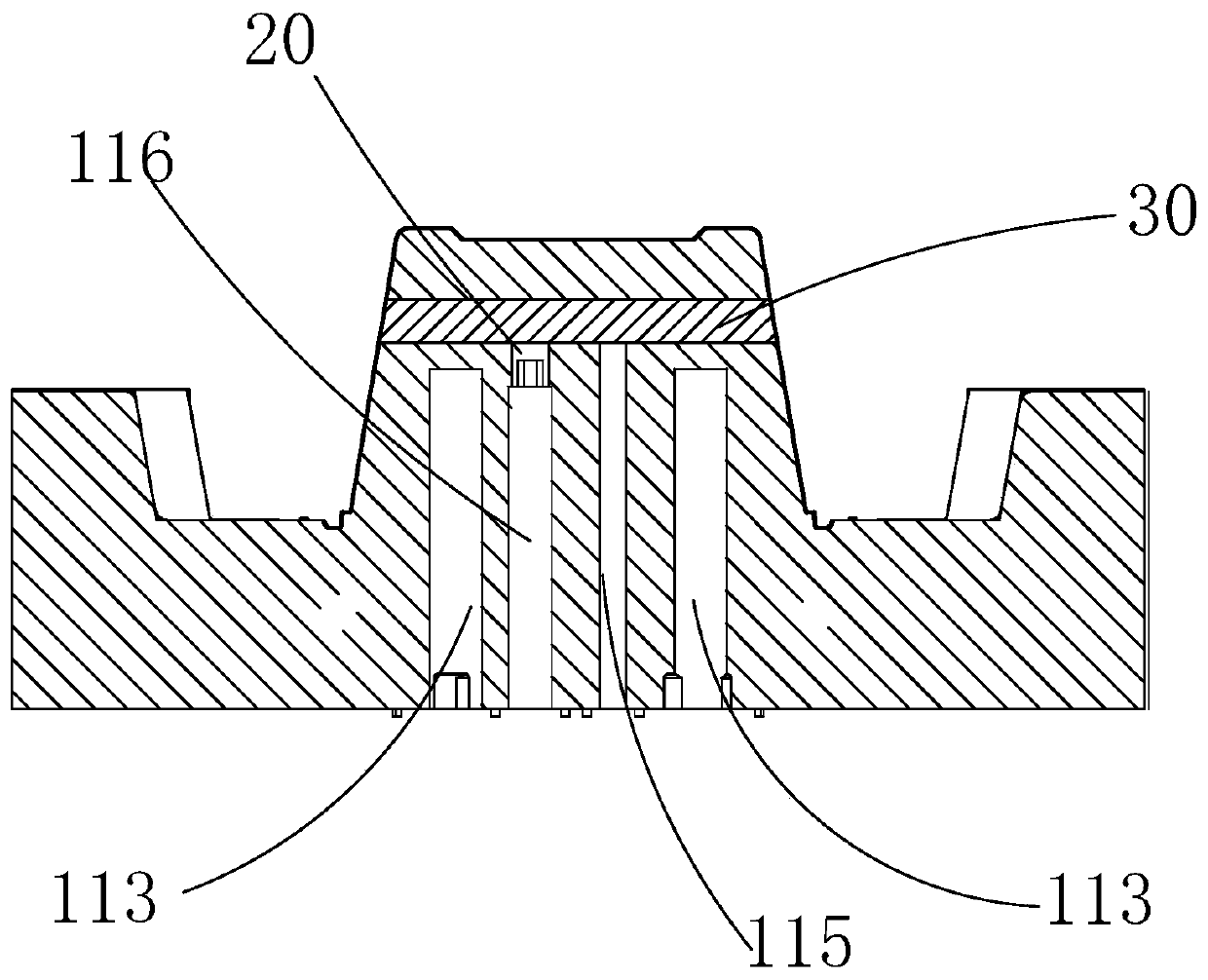

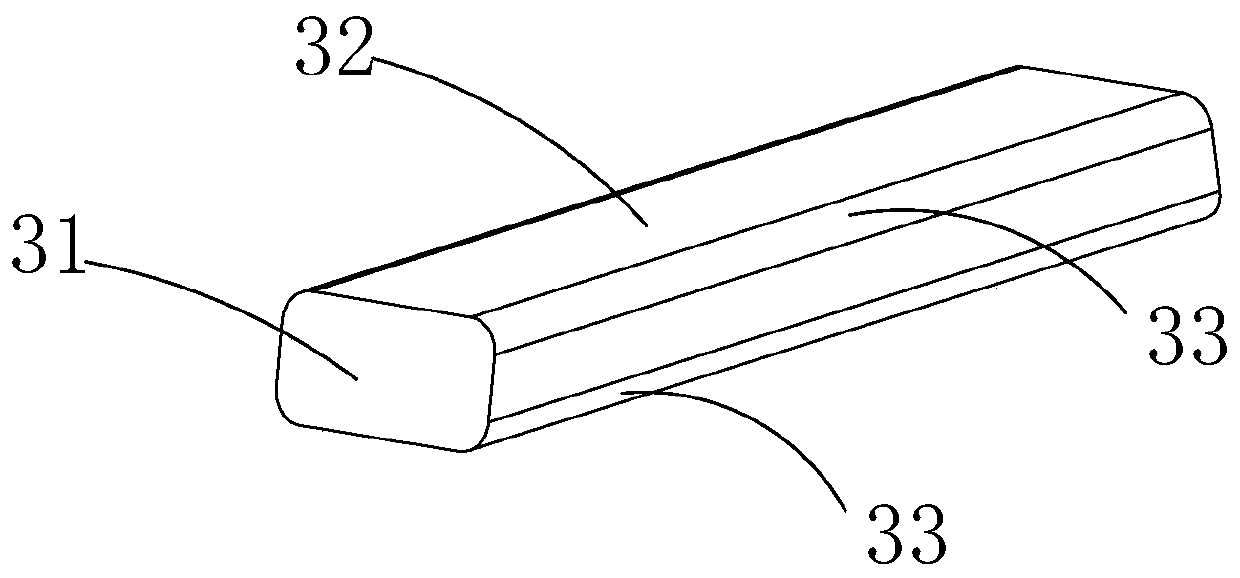

[0022] see Figure 1-4 , this embodiment discloses an insert-type demoulding mechanism, which includes a movable mold 11 and a core 110 formed in the middle of the movable mold 11. In this embodiment, the core 110 is used to form a disposable rectangular lunch box, which is thin-walled and deep Cavity-type plastic parts, the core 110 is an integrated structure, and a side blow hole is opened inside it. The side blow hole runs through the entire core 110 horizontally and communicates with the corresponding air flow channel. The air flow channel is formed inside the core 110. , and its axial direction is consistent with the height direction of the core 110. The height direction of the core 110 in this embodiment refers to the movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com