Equipment for atomizing ultrafine powder, cement, water reducer and water for concrete mixing

An ultra-fine powder and concrete technology, applied in clay preparation devices, cement mixing devices, mixing operation control, etc., can solve problems such as inability to clean the interior, difficulty in discharging the mixture, and adverse effects on the mixing quality of the mixture. The effect of manpower input and material loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below, but the implementation scope of the present invention is not limited to the following embodiments.

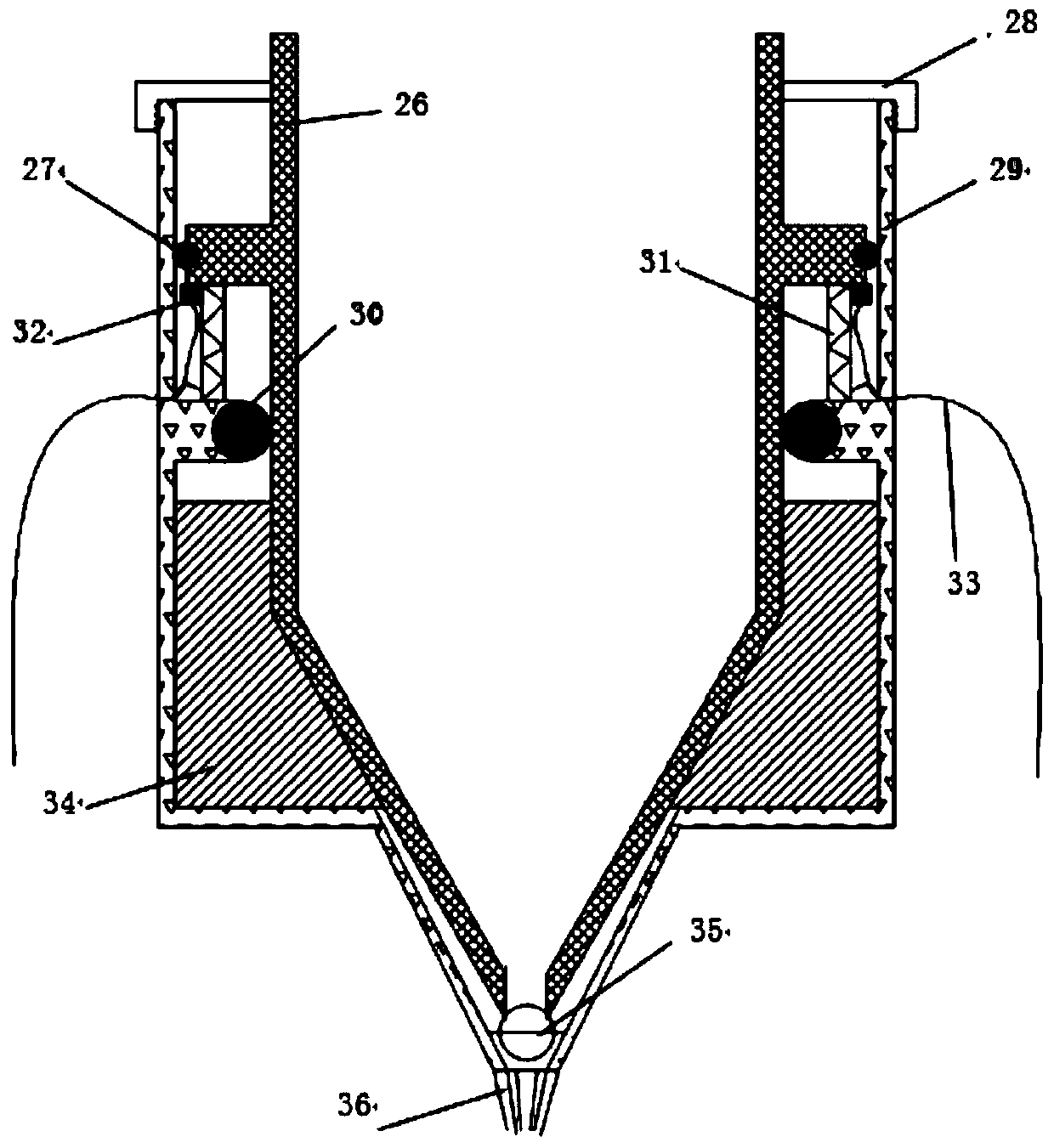

[0021] Such as Figure 1-Figure 4 As shown, the equipment for superfine powder, cement, water reducing agent and water atomization for concrete mixing includes several material weighing feeding bins, several liquid weighing feeding bins, atomizing bins, mixing bins, several The material weighing feeding bin and several liquid weighing feeding bins are arranged on the upper part of the atomizing bin, and the stirring bin is fixed at the lower end of the atomizing bin, and a blower 4 is arranged at the discharge port of the material weighing feeding bin. The discharge port of the liquid weighing feeding bin is provided with an atomization chamber 6.

[0022] The mixing chamber is connected with the atomizing chamber through connecting bolts 15, and there is a rubber belt 23 for sealing between the stirring chamber a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com