Chemical process fault diagnosis method for adaptive kernel principal component analysis

A nuclear principal component analysis and fault diagnosis technology, applied in program control, instrument, test/monitoring control system, etc., can solve the problems of real-time diagnosis difficulty, diagnosis accuracy limitation, manpower and material resource consumption, etc., and achieve adaptive and targeted processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

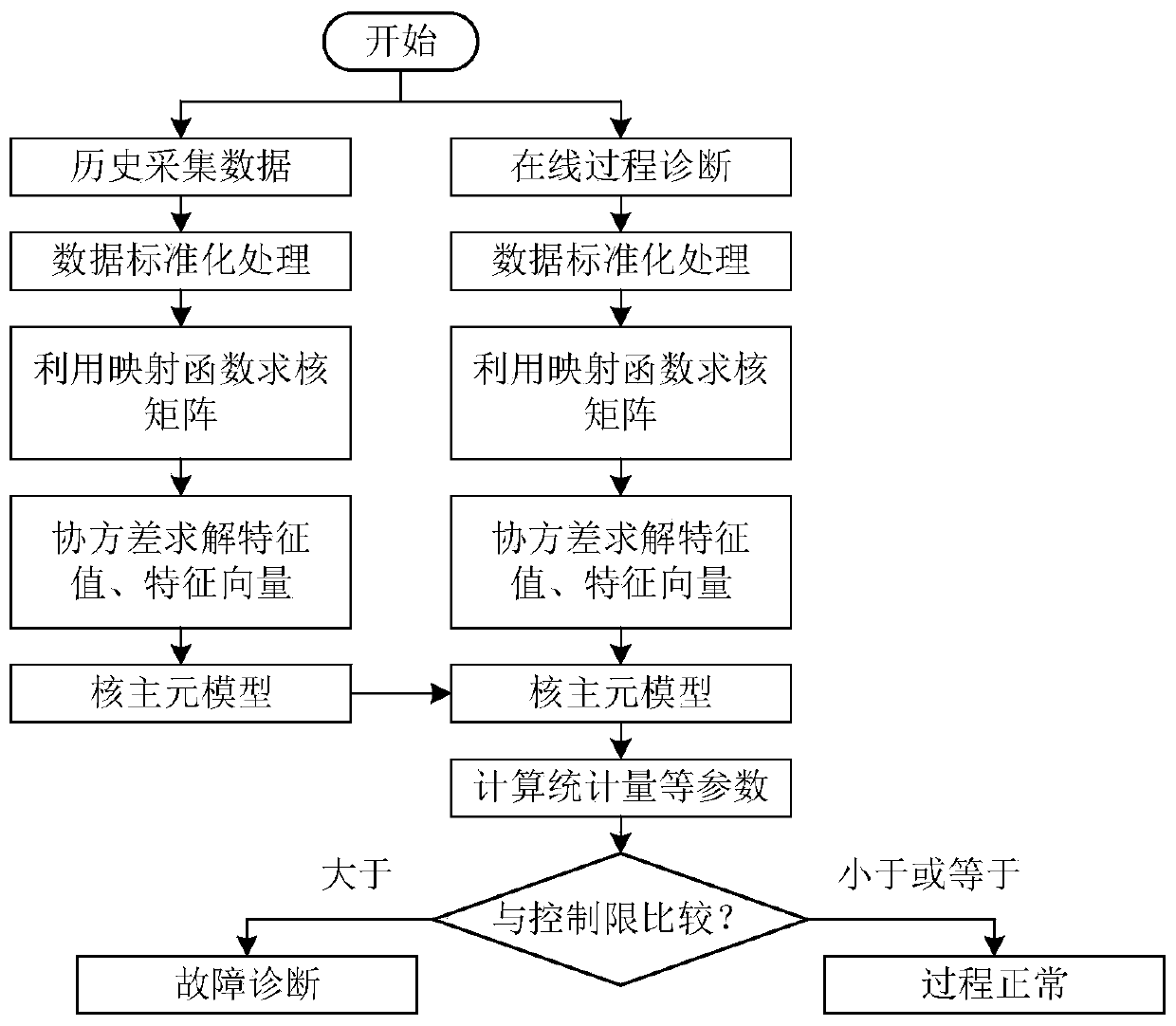

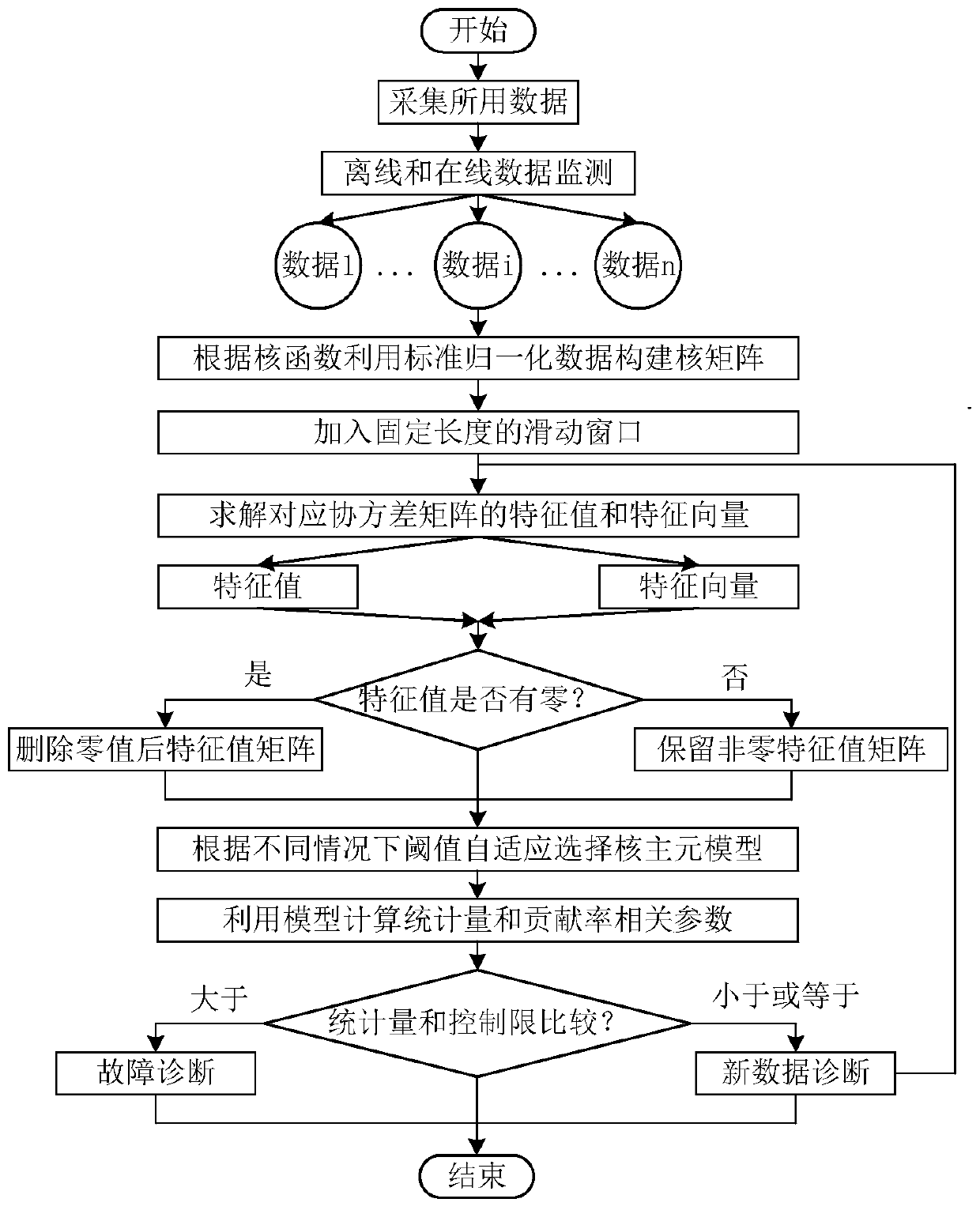

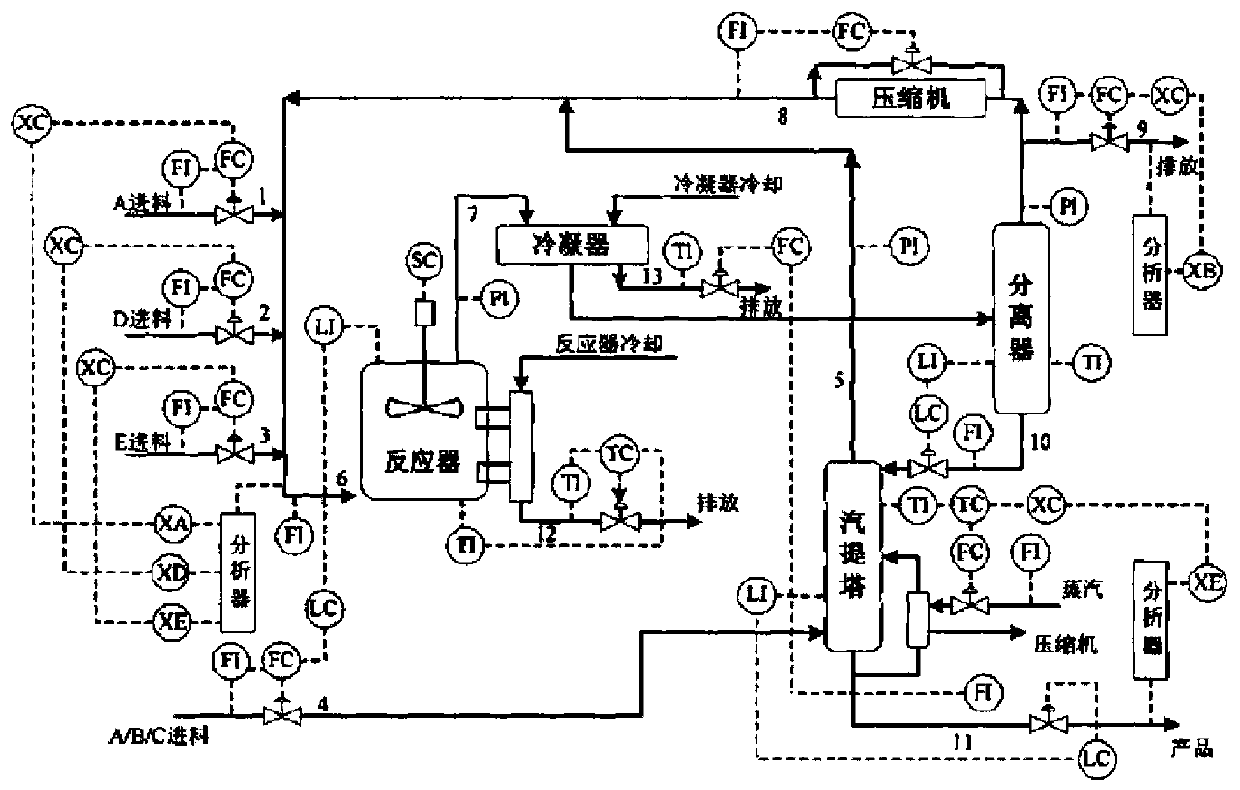

[0072] This embodiment obtains the corresponding kernel matrix and covariance matrix according to the kernel function, solves the eigenvalues of the covariance matrix, sets different thresholds according to whether the eigenvalues are zero, uses the threshold method to adaptively select the kernel principal component model, and adds A sliding window with a suitable length enables adaptive and targeted processing of chemical process fault diagnosis.

[0073] This embodiment provides a chemical process fault diagnosis method of adaptive kernel principal component analysis. This fault diagnosis method obtains the corresponding kernel matrix and covariance matrix according to the kernel function, and solves the eigenvalue of the covariance matrix. According to whether the eigenvalue has In the case of zero, different thresholds are set, and the threshold method is used to adaptively select the kernel principal component model, and a sliding window with a suitable length is adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com