Compact 2X high-definition zoom glass-plastic lens and imaging method thereof

A technology with compact structure and lens, applied in optical components, optics, instruments, etc., can solve the problems of low cost, increased product cost, complex structure, etc., and achieve the effect of solving the problem of insufficient clarity, reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

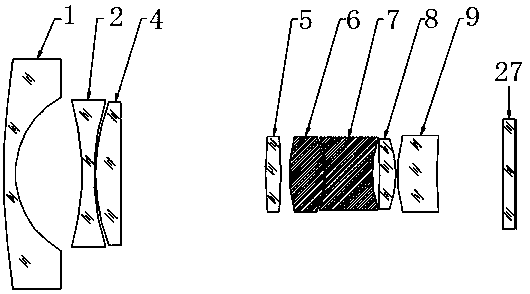

Method used

Image

Examples

Embodiment 2

[0022] Embodiment 2: On the basis of Embodiment 1, in this embodiment, the optical structure composed of the front group lens A and the rear group lens B has reached the following optical technical indicators:

[0023] Focal length: f'=2.8mm;

[0024] Relative aperture F=1.4;

[0025] Field of view: 2w≥137° (image square field of view 2η′≥Ф6.6mm);

[0026] Distortion: <50%;

[0027] Resolution: Compatible with 3 million pixel high resolution CCD or CMOS camera;

[0028] The total length of the optical path ∑≤23mm, the optical back focus L'≥5.5mm;

[0029] Applicable spectral line range: 480~850nm.

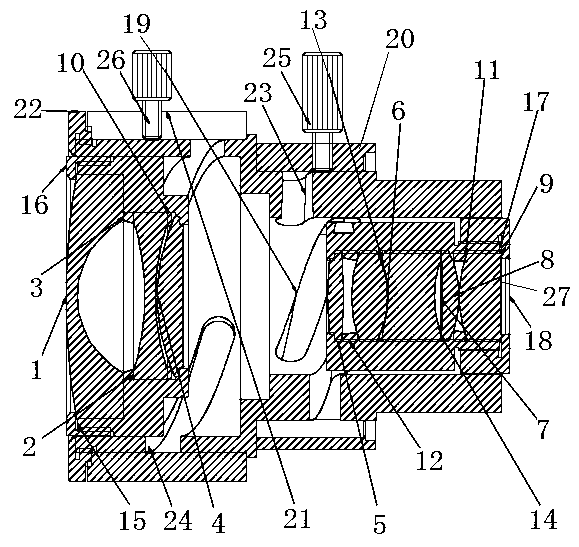

[0030] In this embodiment, in this embodiment, in order to ensure the air space between the lenses in the front group lens A and the rear group lens B, and to ensure the stability and fixity of the lens assembly, the first meniscus lens A and the biconcave lens A A first spacer 3 is arranged between them, a second spacer 10 is arranged between the biconcave lens A and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com