A method for detecting a motor rotor

A technology of motor rotor and detection method, which is applied in the direction of machine/structural component testing, static/dynamic balance testing, measuring devices, etc., which can solve problems such as bending, deformation, and pass rate of motor shafts and other accessories, so as to ensure delivery Quality, enhancement of contact area, effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention discloses a detection method of a motor rotor, comprising the following steps:

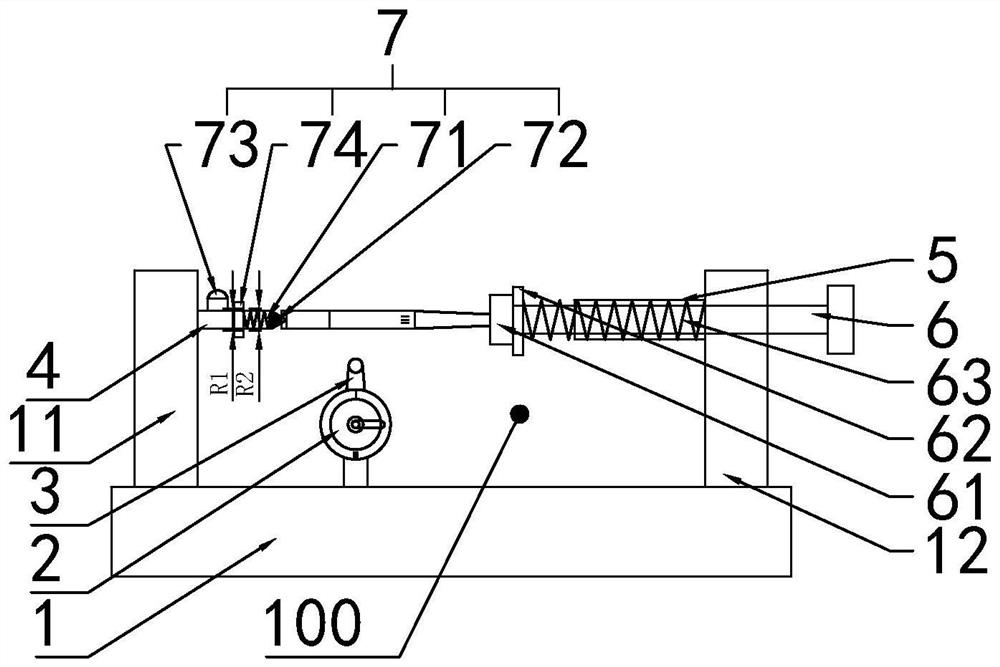

[0033] S1 first rotor shaft runout detection: through the motor rotor runout detection device, the motor shaft is tested for circular runout;

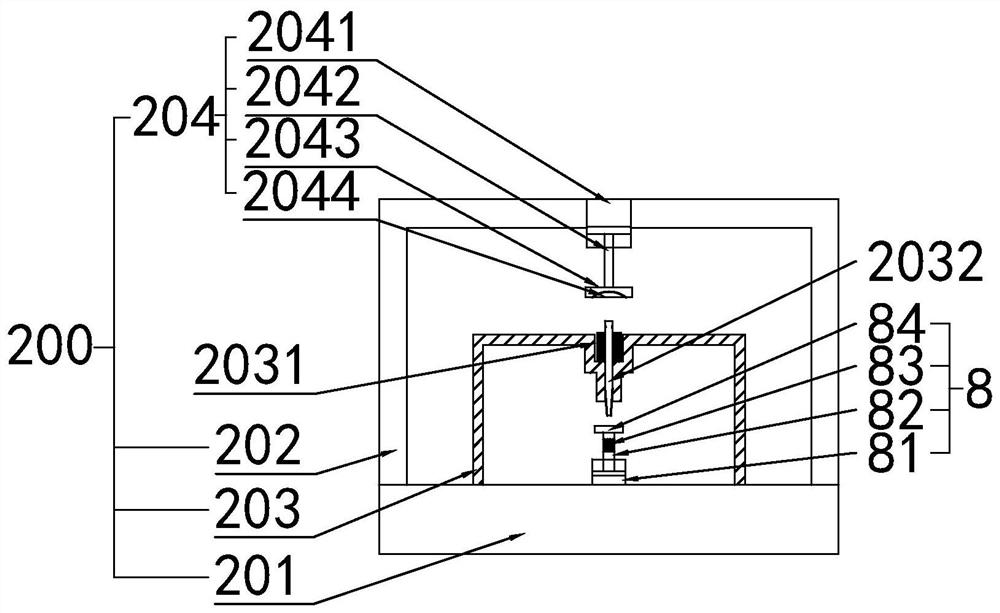

[0034] S2 Finale: Press the rotor shaft that has passed the circular runout test into the inner hole of the rotor through a pneumatic press;

[0035] S3 The second round runout detection of the rotor shaft: the circular runout detection of the rotor shaft after the finale step;

[0036] S4 Rotor initial position detection: The position of the rotor on the rotor shaft is detected by the distance detection device installed on the circular runout detection device;

[0037] S5 Rotor binding force detection: through the detection of the rotor binding force detection device, the two ends of the rotating shaft are supported, and then the rotor is squeezed along the horizontal direction of the rotor shaft by the extrusion block, and the displ...

Embodiment 2

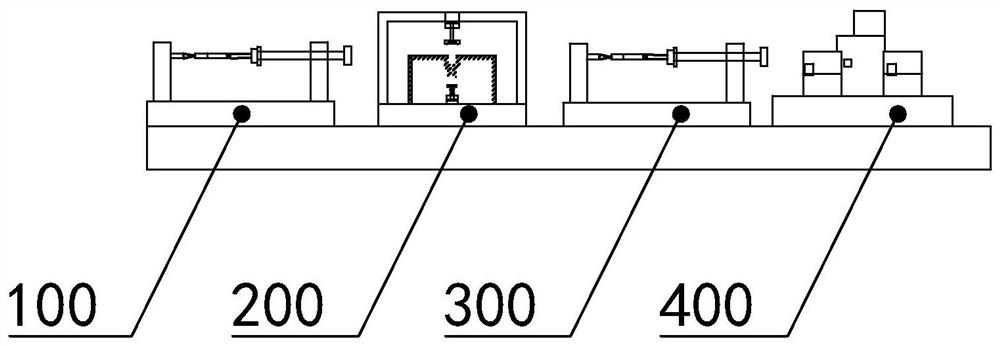

[0043] Such as Figure 1-Figure 5 As shown, the present invention also discloses a detection device for a motor rotor. In the specific embodiment of the present invention, according to the preparation sequence, it includes a circular runout detection device 100, a distance detection device 200, a rotor binding force detection device 300, and a displacement detection device 400. And the rotor dynamic balance testing machine 500.

[0044] In a specific embodiment of the present invention, the circular runout detection device 100 includes a first base 1, a measuring gauge 2, and a first clamping seat 11 and a second clamping seat installed on both sides of the upper surface of the first base 1 12. The measuring gauge 2 is equipped with a circular runout measuring head 3, the measuring gauge 2 is installed vertically on the first base 1, and the circular runout measuring head 3 faces upwards; the inner side of the first clamping seat 11 is equipped with a tip 4 , a sleeve 5 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com