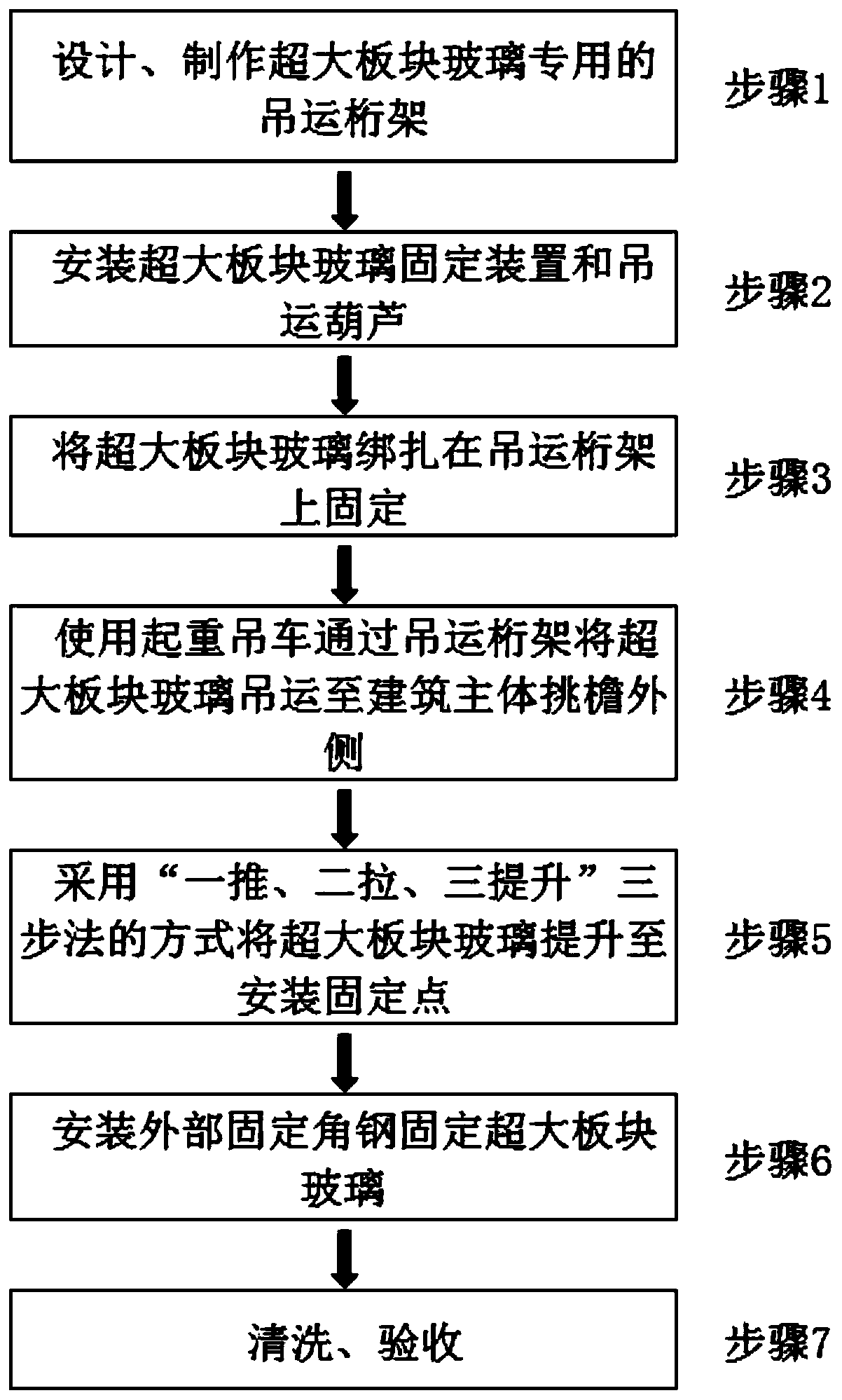

Oversized plate rib-free full-glass curtain wall mounting construction method

A construction method and all-glass technology, applied to walls, building components, buildings, etc., can solve the problems of high transportation costs, complex installation structures, and occupation of indoor and outdoor space, and achieve simple lifting structure, simple structure, and convenient lifting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

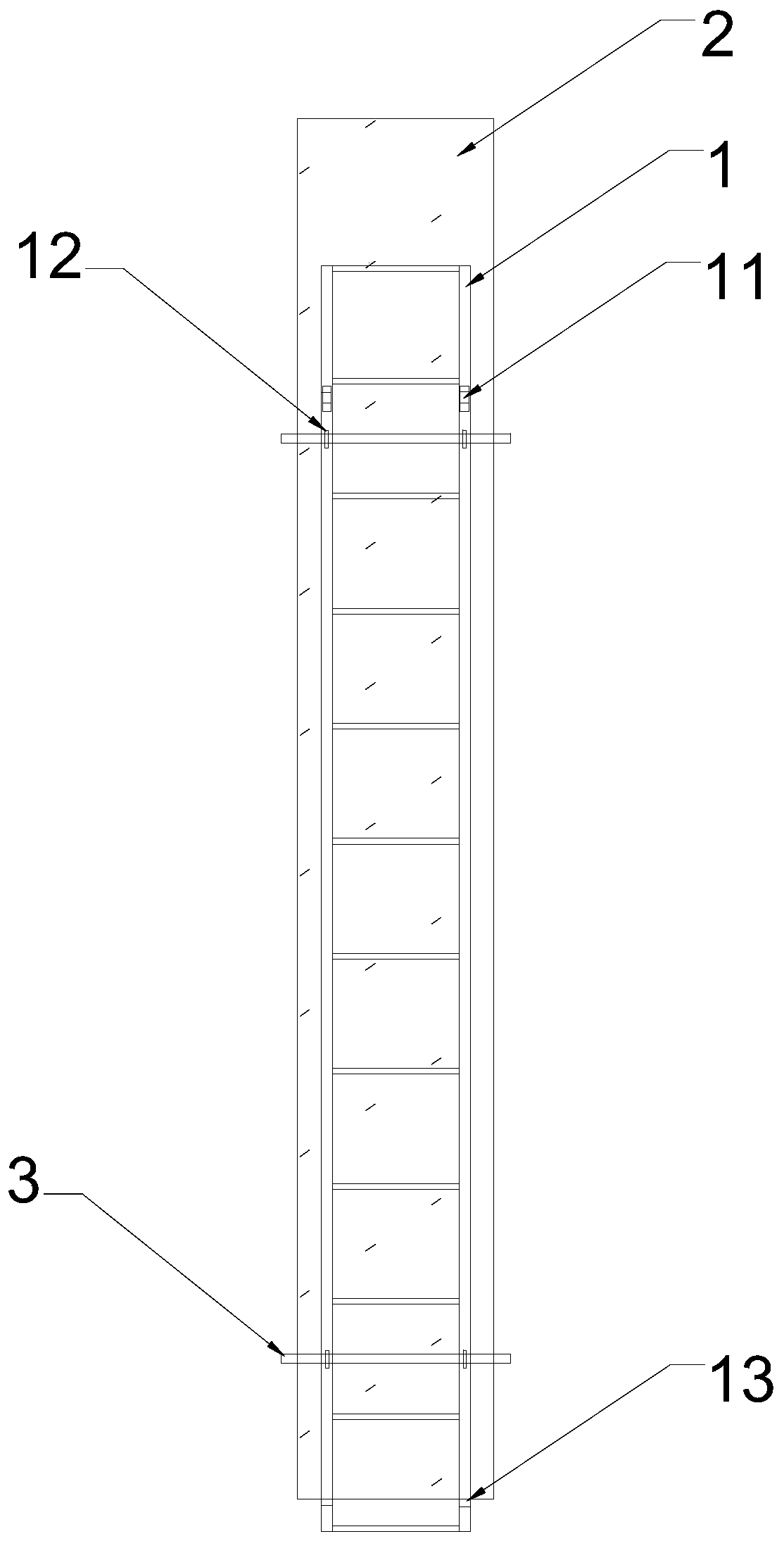

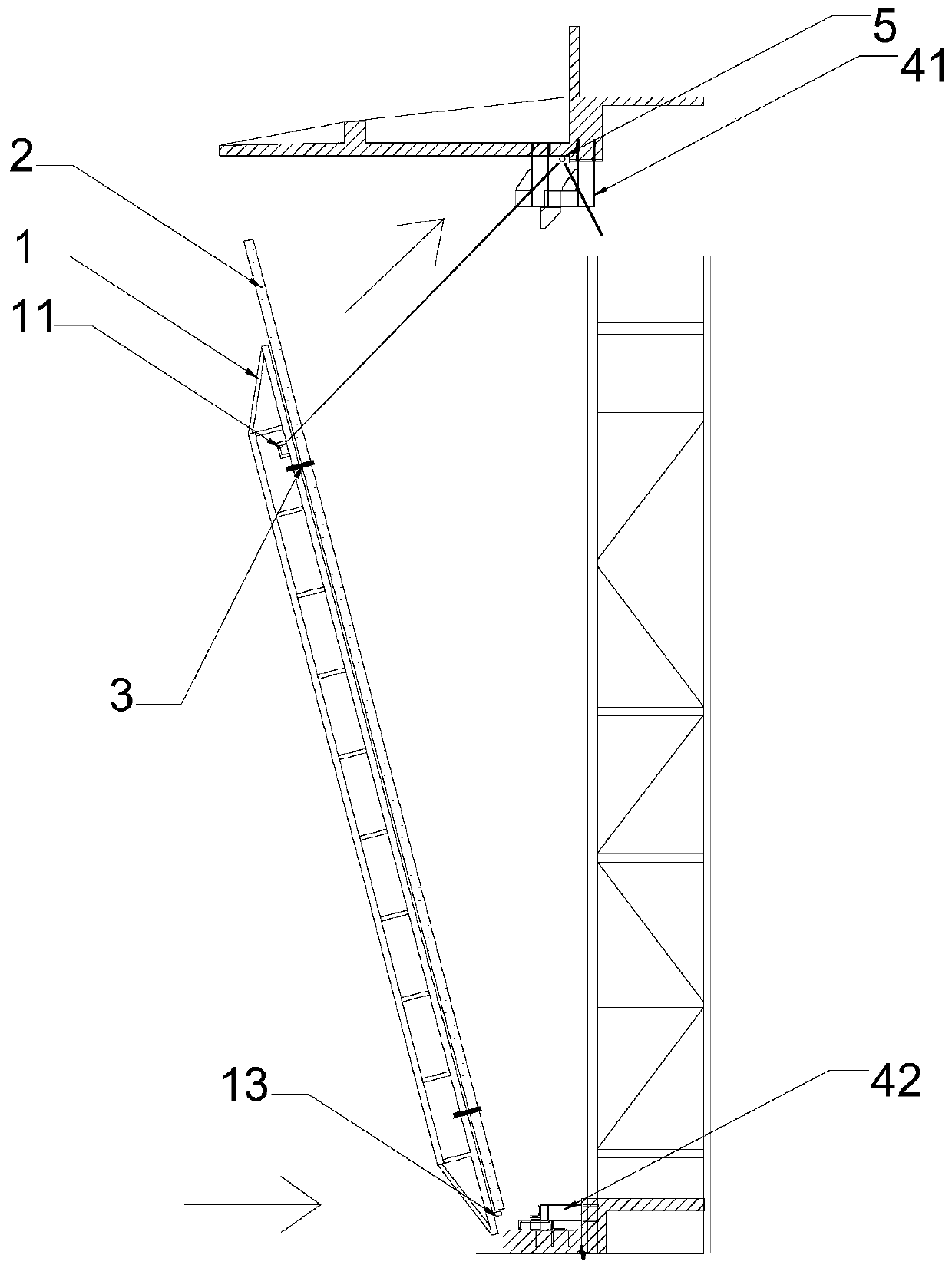

[0032] In step 1, the size of the super large plate glass 2 is 1.8m×12m and the thickness is 50mm, the lifting truss 1 is welded with a 100×50×5mm square tube, the size is 1.6m×11m, the height of the fixing protrusion 13 is 30mm, and the buffer material It is a 50mm thick rubber and plastic insulation material. There are two hanging pieces 11, which are respectively located on both sides of the upper end of the lifting truss 1. There are four fixing pieces 12, which are symmetrically arranged on both sides of the upper and lower ends of the lifting truss 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com