Inland terminal depot structure

A wharf and inland river technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as easy occurrence of safety problems, unstable bottom pile foundation, easy to be washed by river waves, etc., to achieve good anti-scour effect, not easy to be washed Erosion, strong effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention. The connection methods of fixed arrangement and fixed connection mentioned in this embodiment are common knowledge known to those skilled in the art, such as riveting, screw connection, bolt connection, integral molding, etc., and will not be repeated here.

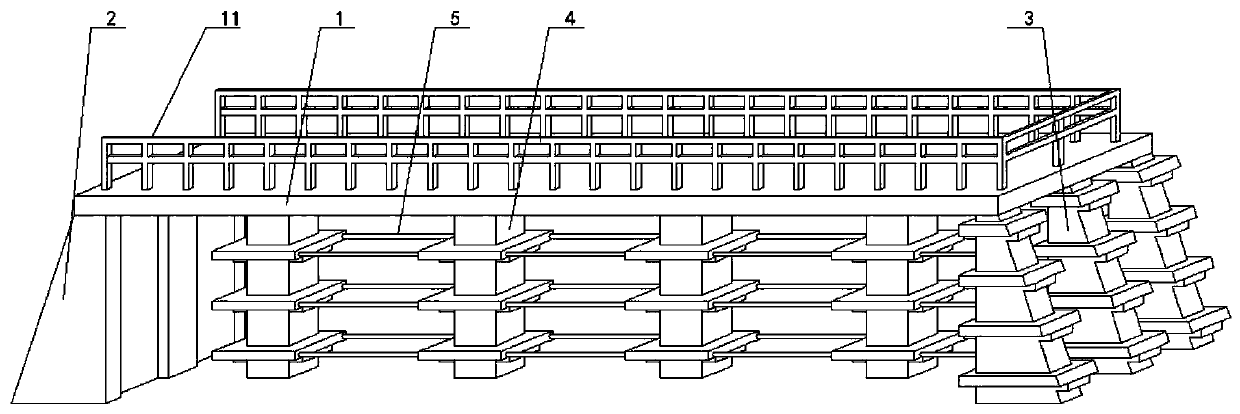

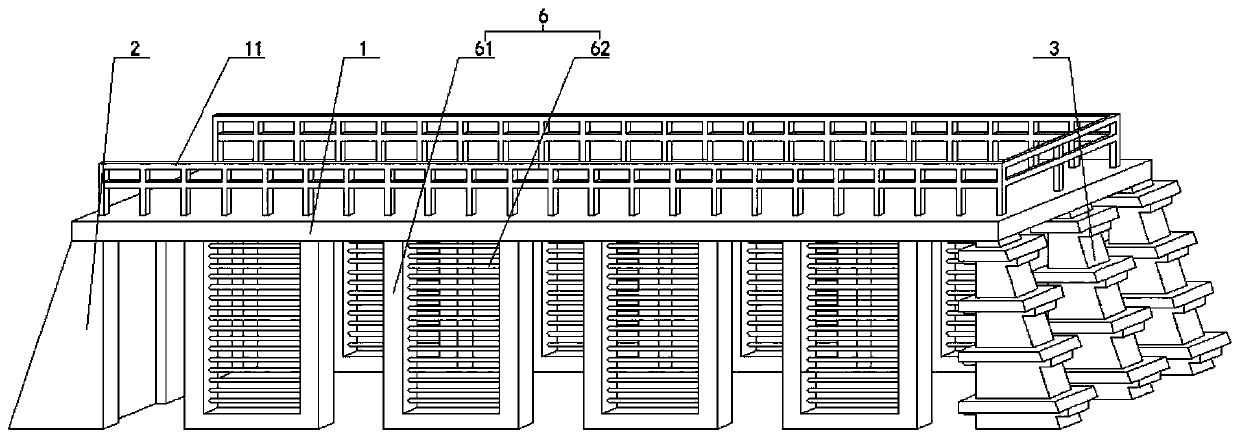

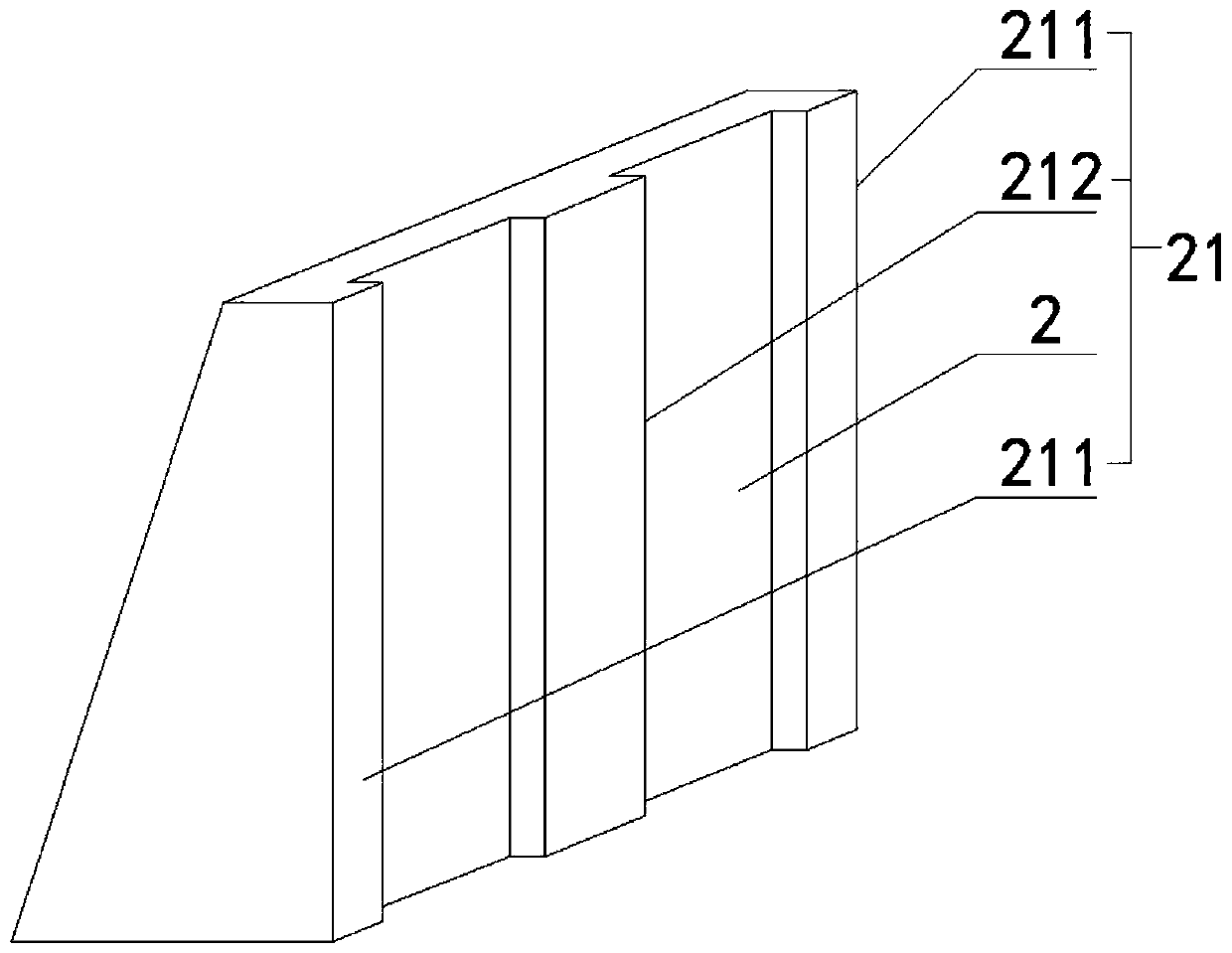

[0023] An inland wharf structure, comprising a wharf platform 1, a docking base 2, three river bases 3 and four supporting bases 4; the wharf platform 1 is a flat structure, and the wharf platform 1 is horizontally arranged Above the river level, one end of the wharf platform 1 is connected to the land; the other end extends to the inla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com