Preparation method of high purity calcium hydroxide

A calcium hydroxide and high-purity technology, applied in the field of preparation of high-purity calcium hydroxide, can solve the problems of low efficiency and complicated operation of calcium hydroxide process, so as to reduce pollution, improve resource utilization efficiency, and improve extraction and impurity removal. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

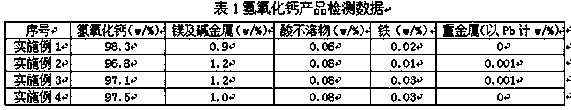

Examples

Embodiment 1

[0019] A kind of preparation method of high-purity calcium hydroxide, it specifically comprises the steps:

[0020] (1) Dry carbide slag under ultrasonic conditions for 1 hour, and then pass through a 250-mesh sieve to obtain carbide slag pretreatment; the ultrasonic drying is carried out at an ultrasonic frequency of 40kHz and a temperature of 50°C;

[0021] (2) Stir and mix the calcium carbide slag pretreated product obtained in step (1) and deionized water at a ratio of 1:12 by weight for 45 minutes to obtain a mixed solution, and then mix the mixed solution at a stirring speed of 400r / min. The liquid and the organic extractant are mixed according to the weight ratio of 10:2, extracted at 60°C for 2 hours, then left to stand for 20 minutes, and the organic phase is separated and removed by suction filtration to obtain a solid; the organic solvent is ethanediol It is obtained by mixing alcohol and tributyl phosphate according to the ratio of 4:1 by weight;

[0022] (3) Mix ...

Embodiment 2

[0024] A kind of preparation method of high-purity calcium hydroxide, it specifically comprises the steps:

[0025] (1) Dry carbide slag under ultrasonic conditions for 1.5 hours, and then pass through a 200-mesh sieve to obtain carbide slag pretreatment; the ultrasonic drying is carried out at an ultrasonic frequency of 30kHz and a temperature of 40°C;

[0026] (2) Stir and mix the calcium carbide slag pretreated product obtained in step (1) and deionized water at a ratio of 1:10 by weight for 30 minutes to obtain a mixed solution, and then mix the mixture at a stirring speed of 300r / min Liquid and organic extractant were mixed according to the weight ratio of 10:1, extracted at 80°C for 1 hour, then left to stand for 30 minutes, separated and removed the organic phase, and suction filtered to obtain a solid; the organic solvent was ethylene glycol It is obtained by mixing alcohol and tributyl phosphate according to the ratio of 3:1 by weight;

[0027] (3) Mix the solid obta...

Embodiment 3

[0029] A kind of preparation method of high-purity calcium hydroxide, it specifically comprises the steps:

[0030] (1) Dry carbide slag under ultrasonic conditions for 2 hours, and then pass through a 300-mesh sieve to obtain carbide slag pretreatment; the ultrasonic drying is carried out at an ultrasonic frequency of 60kHz and a temperature of 60°C;

[0031] (2) Stir and mix the calcium carbide slag pretreated product obtained in step (1) and deionized water at a ratio of 1:15 by weight for 60 minutes to obtain a mixed solution, and then mix the mixture at a stirring speed of 500r / min The liquid and the organic extractant are mixed according to the weight ratio of 10:1.5, extracted at 50°C for 1.5 hours, then left to stand for 15 minutes, and the organic phase is separated and removed, followed by suction filtration to obtain a solid; the organic solvent is ethylene glycol It is obtained by mixing alcohol and tributyl phosphate according to the ratio of 2:1 by weight;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com