A positioning method for rubber groove brackets used for stern ramps of large ships

A bracket positioning and rubber groove technology, which is applied to ships and other directions, can solve the problems of inconsistent rubber compression in the sealing groove, affecting the sealing performance of the stern channel, and inconsistent gaps, so as to shorten the ship construction cycle, shorten the installation cycle, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with specific embodiment:

[0027] A method for positioning a stern springboard rubber groove bracket for a large ship stern springboard, comprising the following steps:

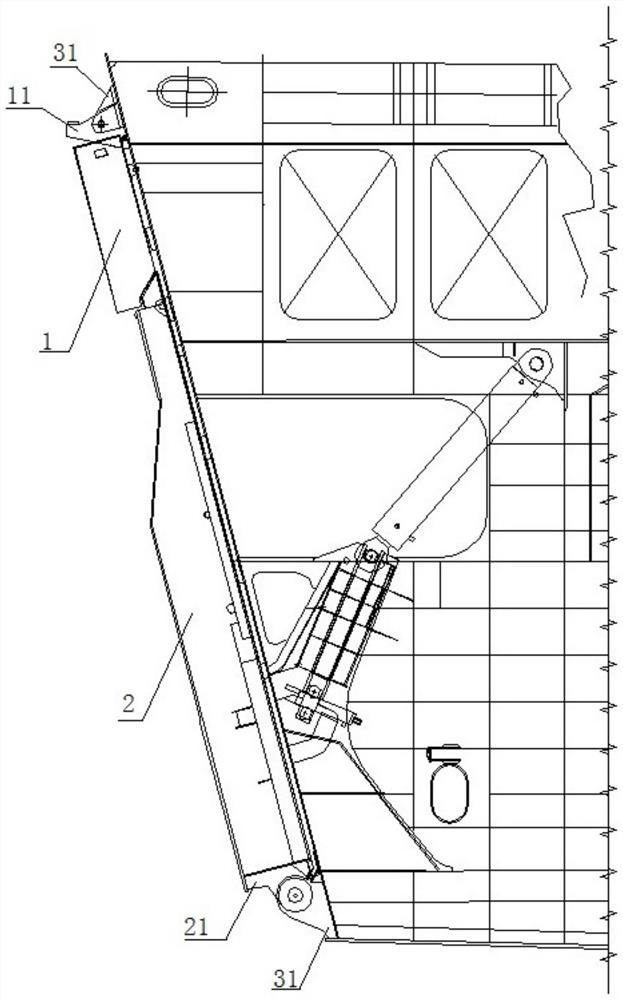

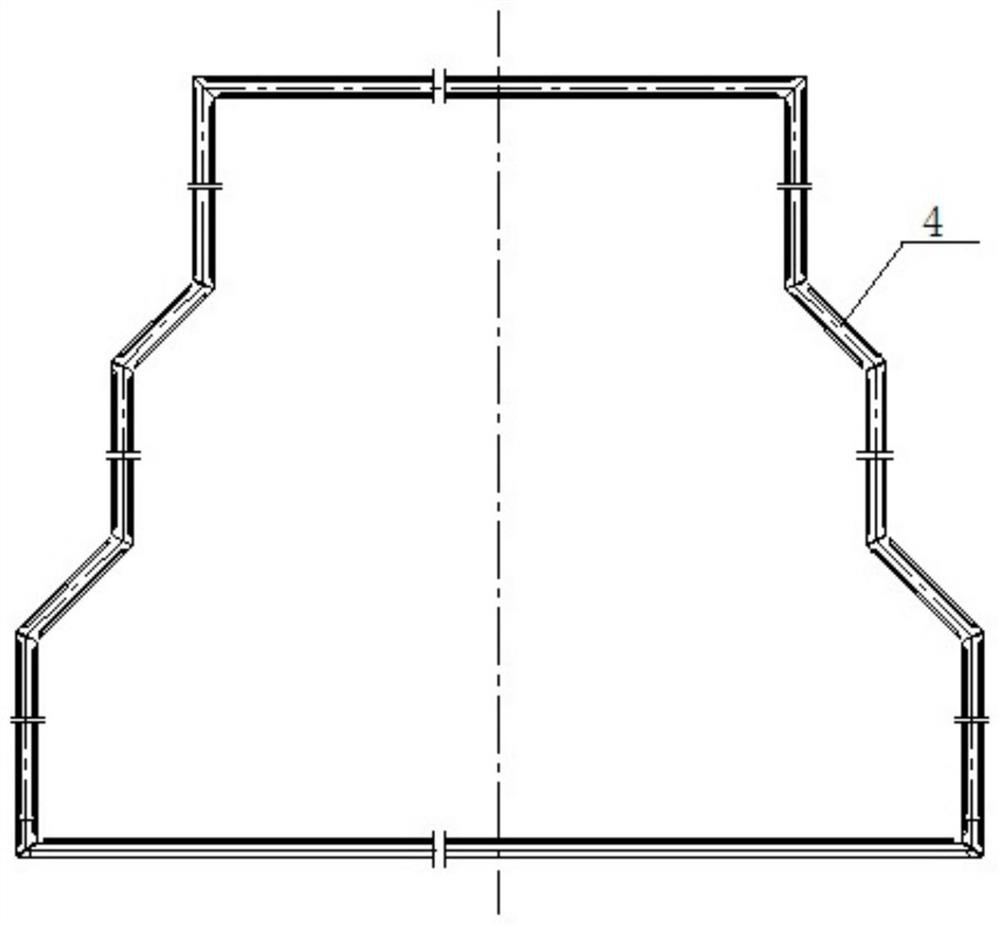

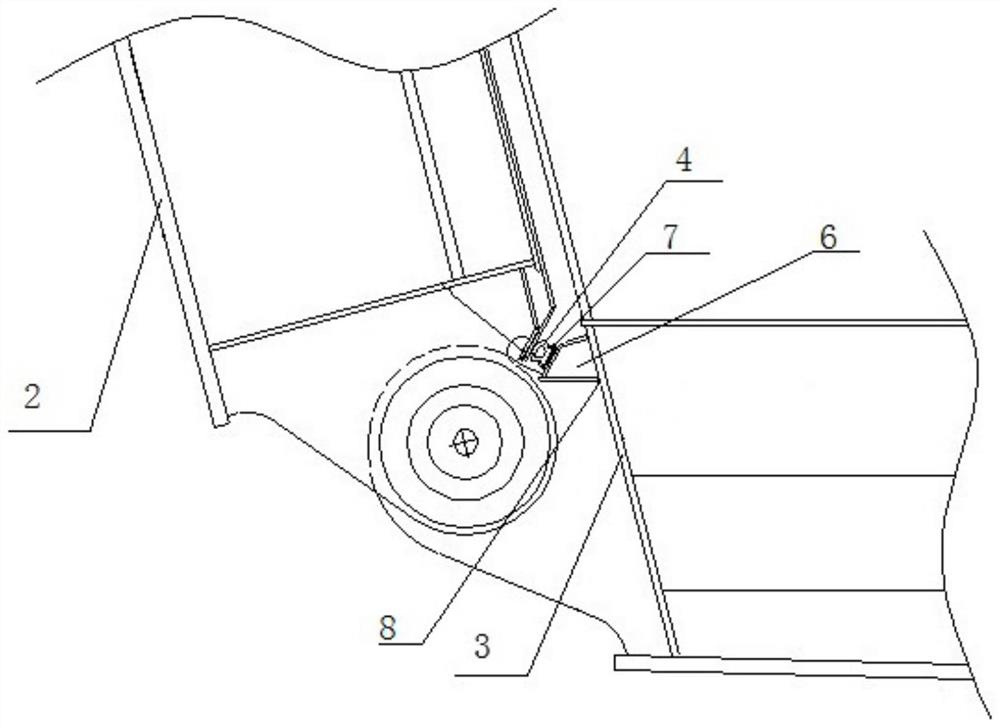

[0028] The first step: According to the up, down, left, and right positions of the stern door 1 and the stern ramp 2 relative to the door frame of the stern sealing plate 3 and the compression amount of the rubber 4, hoist the stern door 1 and the stern ramp 2 to the pre-installed position, and use a chain hoist, limiter The stern door 1 and the stern ramp 2 are fixed firmly by the positioning board, and the stern seal hinge eye plate 31 is positioned according to the positions of the stern door hinge eye plate 11 on the stern door 1 and the stern ramp hinge eye plate 21 on the stern ramp 2 respectively. Such as figure 1 After the stern door 1 and the stern ramp 2 are hoisted, the stern seal hinge eye plate 31 is welded, and then the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com