Lapping component of circular tube beam and girder

A technology of round tubes and components, which is applied in the field of overlapping components between round tube beams and girders, and can solve problems such as insufficient structural strength, insufficient torsional rigidity, and insufficient rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

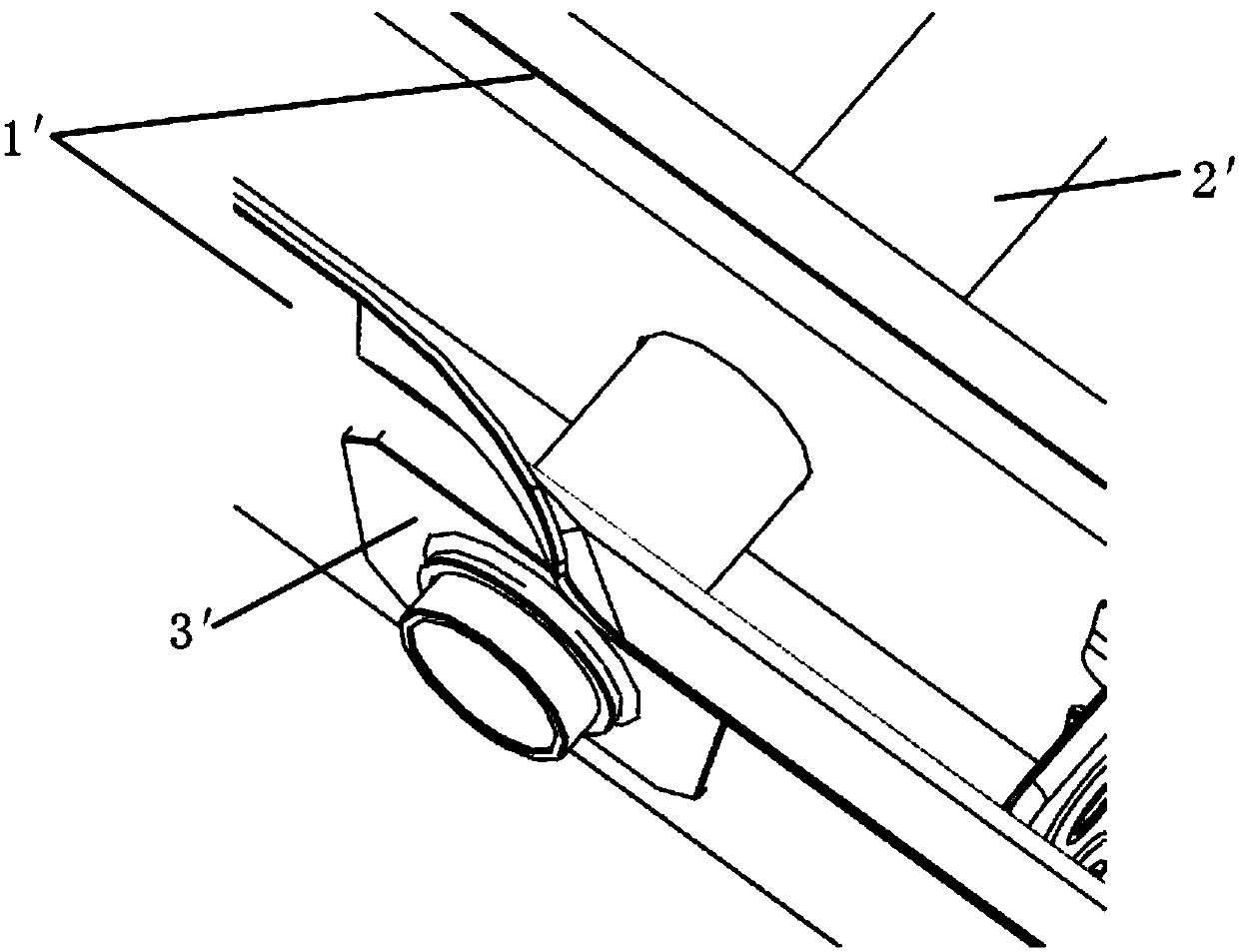

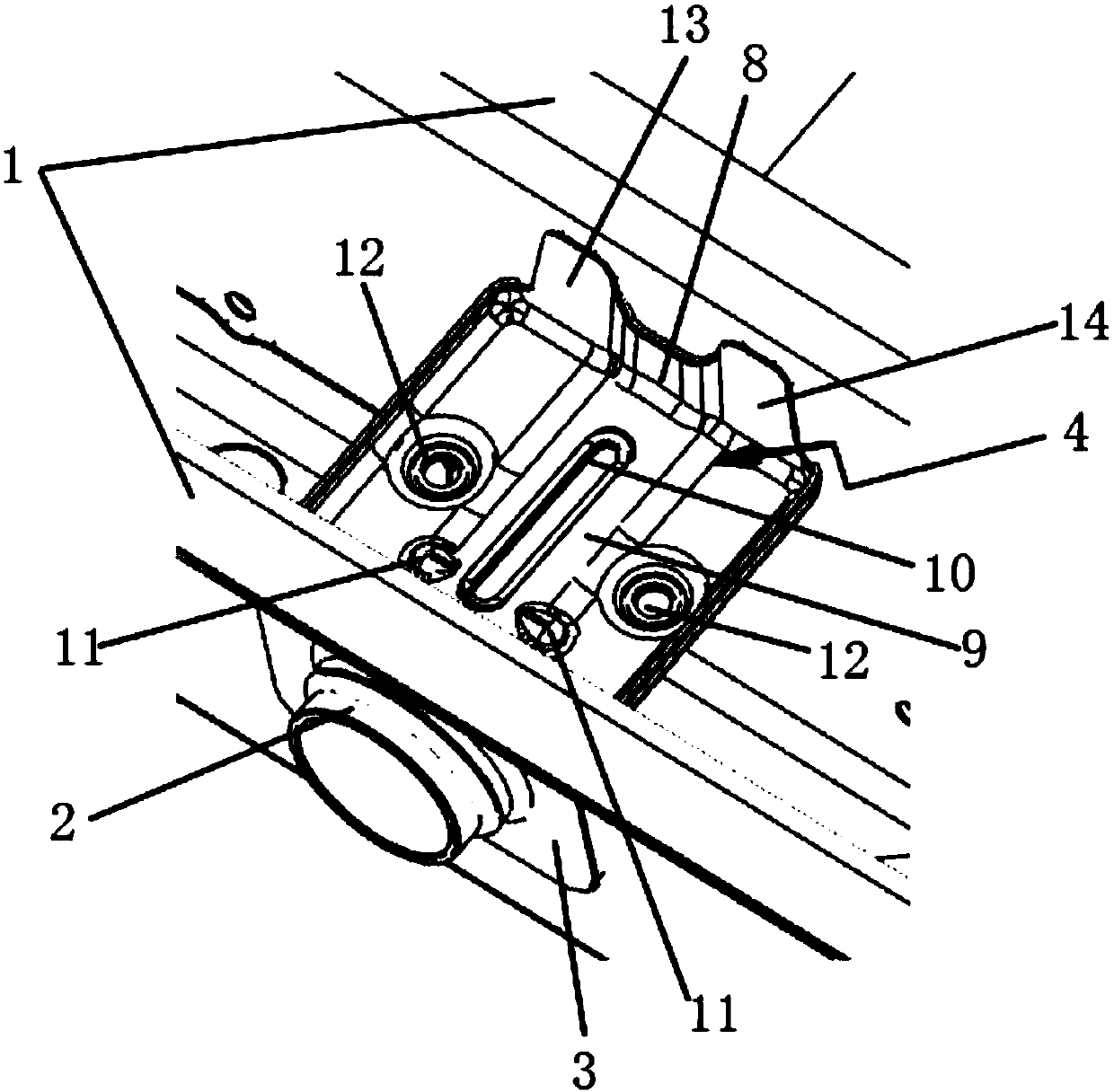

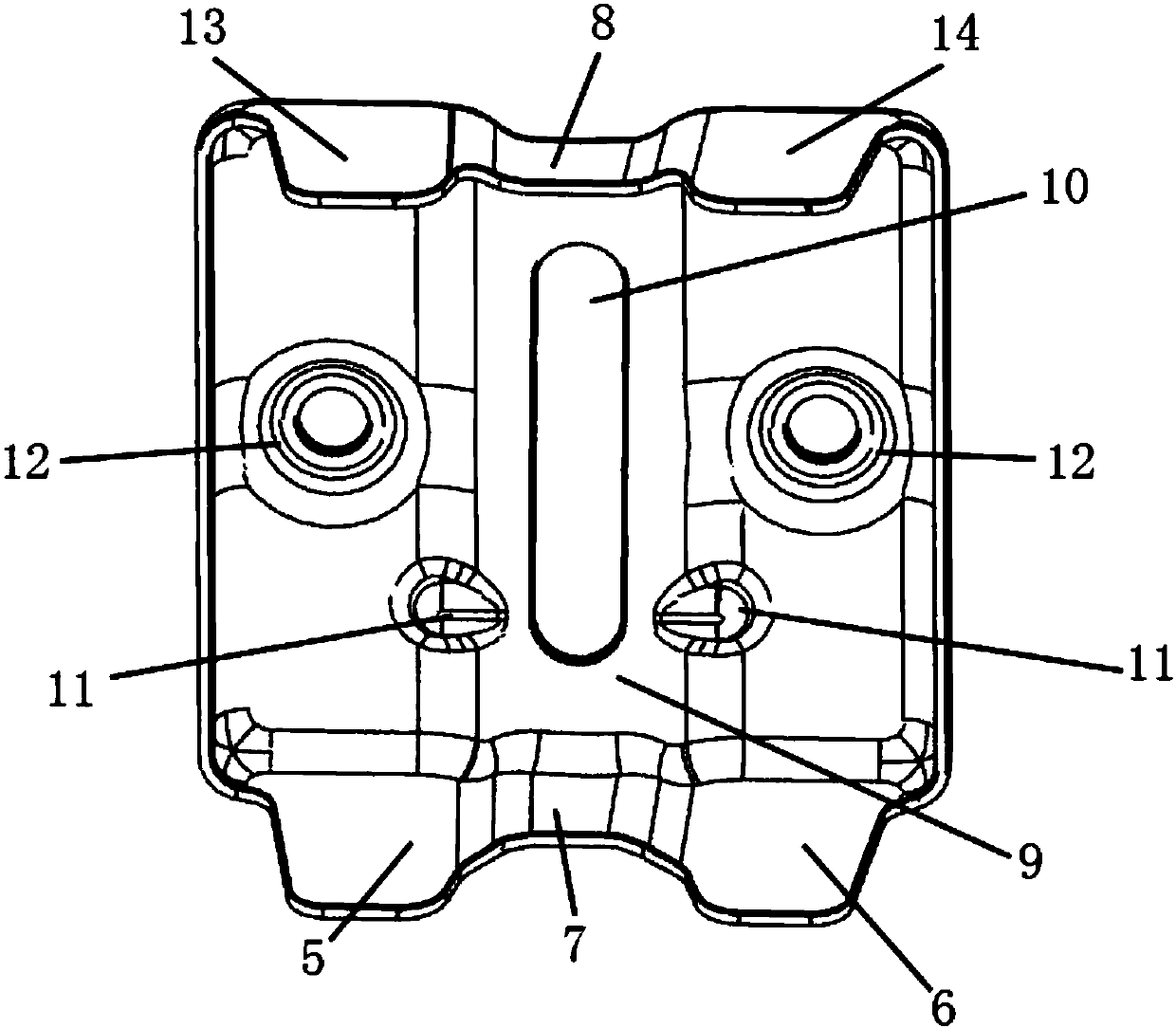

[0026] The following with attached figure 2 and image 3 A lap joint assembly of a circular tube beam and a girder of the present invention is further described in detail. Instructions attached figure 2 The oblique front direction is front, the oblique back direction is rear, the left side direction is left, the right side direction is right, the upper side direction is up and the lower side direction is down.

[0027] For a lap joint assembly between a circular tube beam and a girder of the present invention, please refer to figure 2 and image 3 As shown, it includes a round tube beam 2, a girder 1, a girder outer reinforcement plate 3 and a girder inner sealing plate 4, the front end of the round tube girder 2 passes through the inside of the girder 1, and the front end of the round tube girder 2 passes through the The outer reinforcing plate 3 of the girder is fixed on the outside of the girder 1 , the inner sealing plate 4 of the girder is fixed inside the girder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com