Efficient dedusting device used for polishing machine tool

A technology of dust removal device and machine tool, which is applied in the direction of dust removal, cleaning method and utensils, cleaning method using tools, etc., which can solve the problems of worker hazards, debris, dust flying around, and low dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

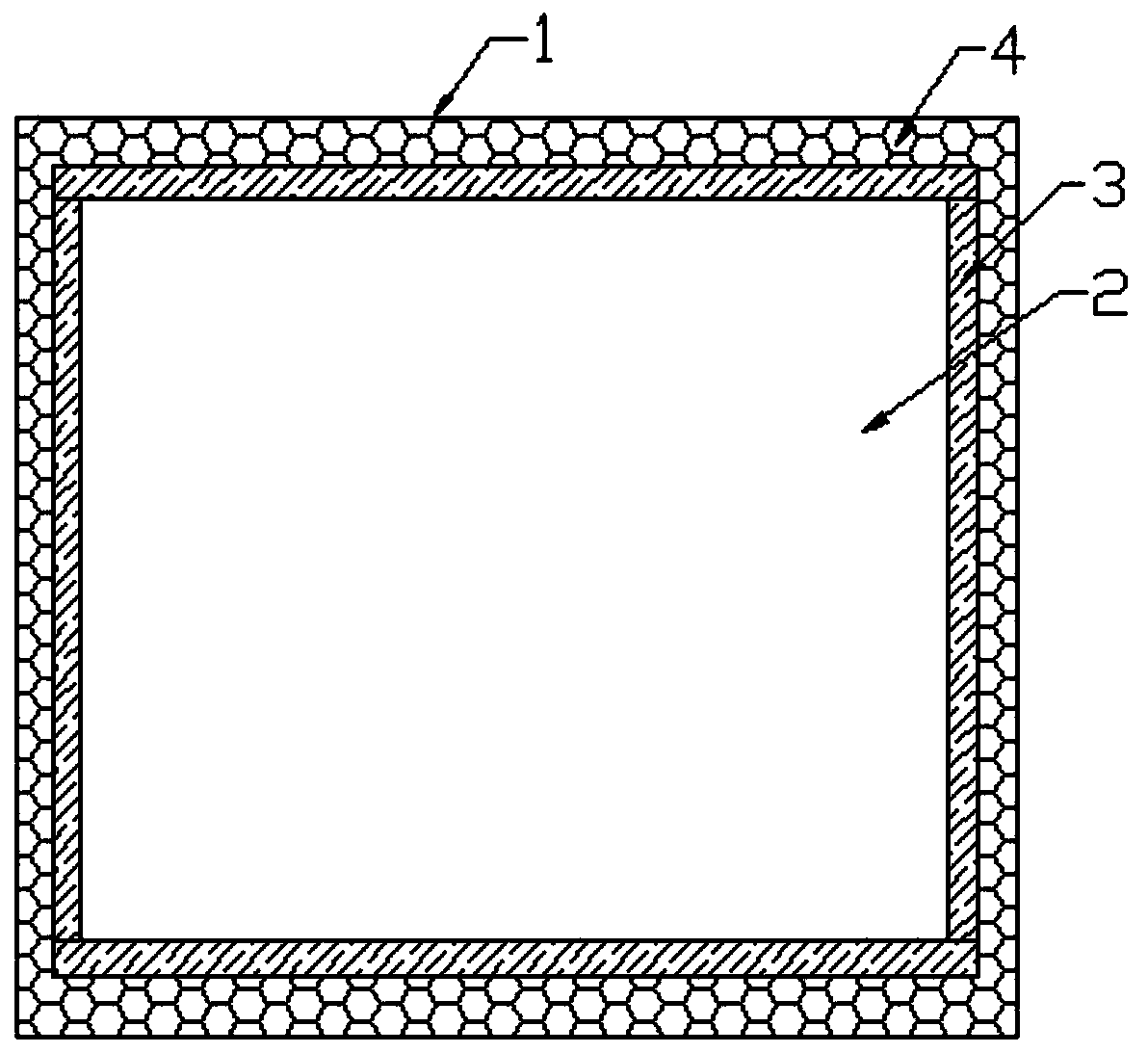

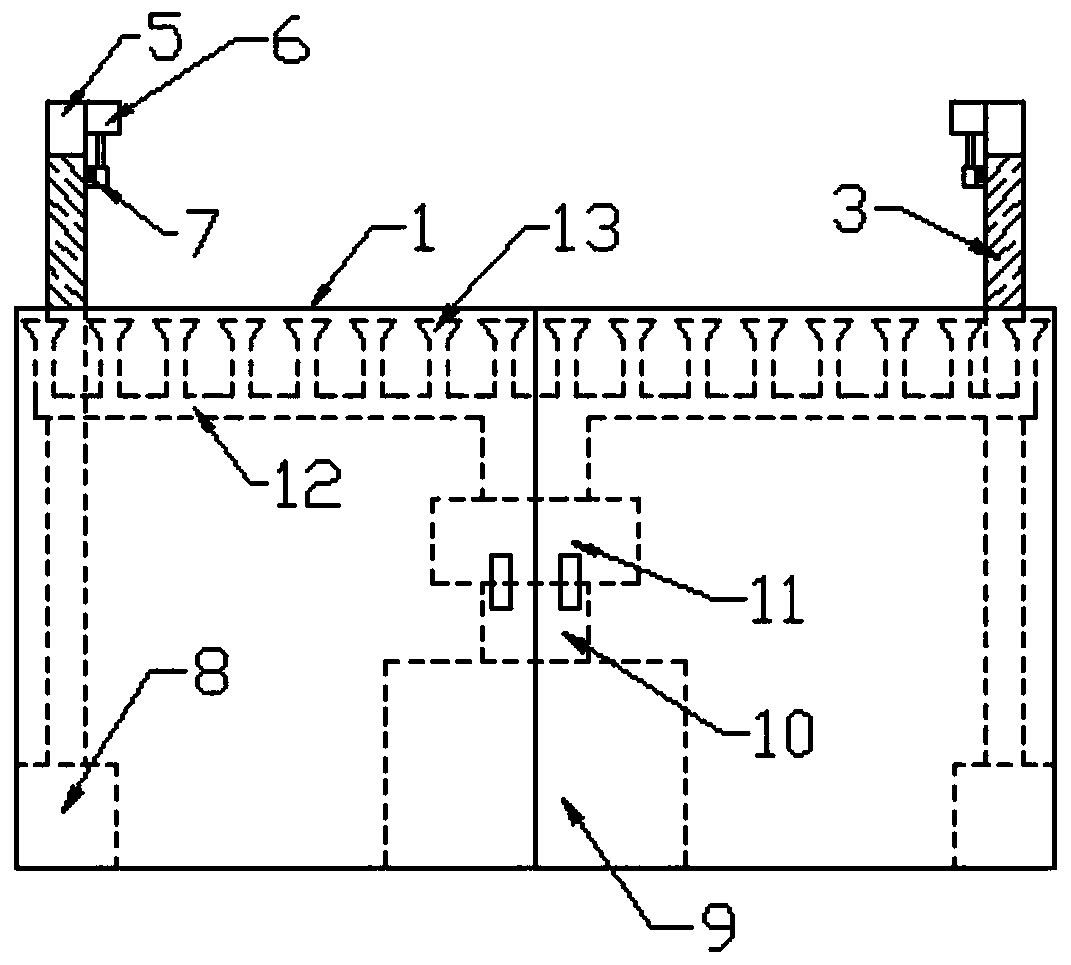

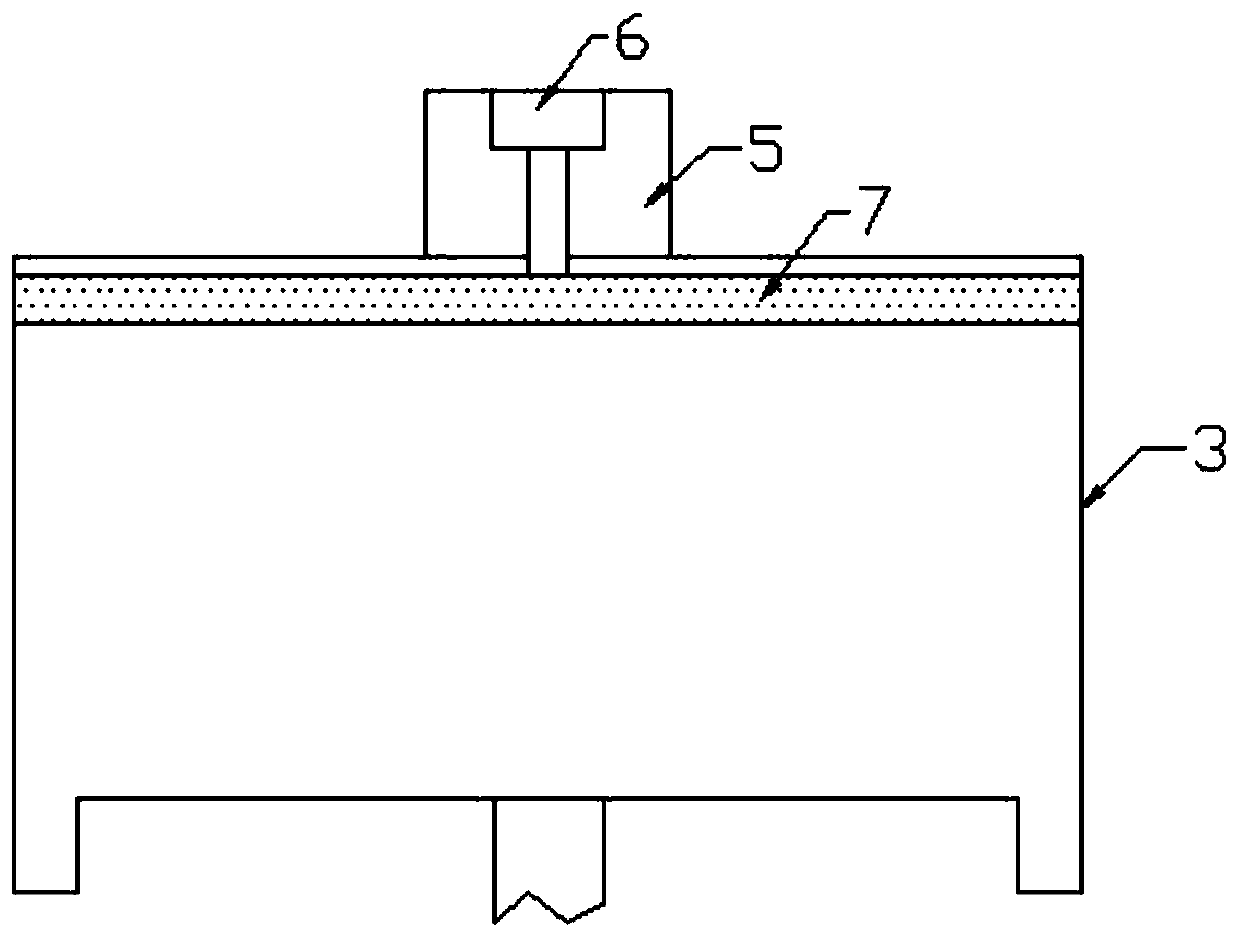

[0019] Example: such as Figure 1-3 As shown, a kind of high-efficiency dust removal device for grinding machine tool of the present invention comprises machine tool 1, and machine tool 1 comprises work area 2, and the four sides of work area 2 are all provided with baffle plate 3, makes baffle plate 3 detritus of work area 2, Dust is blocked within the scope of the work area 2, thereby reducing the inhalation of less dust by personnel working near the machine tool 1; the middle of the bottom end of the baffle 3 is concave, and the middle of the bottom of the baffle 3 is fixed on the second The top of the piston rod of the cylinder 8 is convenient to drive the baffle plate 3 to rise by starting the No. 2 cylinder 8, so that the baffle plate 3 blocks debris and dust within the scope of the work area 2; the table top of the machine tool 1 at the bottom of the baffle plate 3 is Filter screen 4 is made, is convenient to make dust, debris enter the below of machine tool 1 through f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com