Temperature sensor packaging structure and food processor adopting same

A technology of temperature sensor and packaging structure, applied in applications, kitchen utensils, household utensils, etc., can solve the problems of not being able to clean, not disassemble, and affecting the sensitivity of the temperature sensor, so as to ensure normal conduction, prolong the service life, and facilitate mutual The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

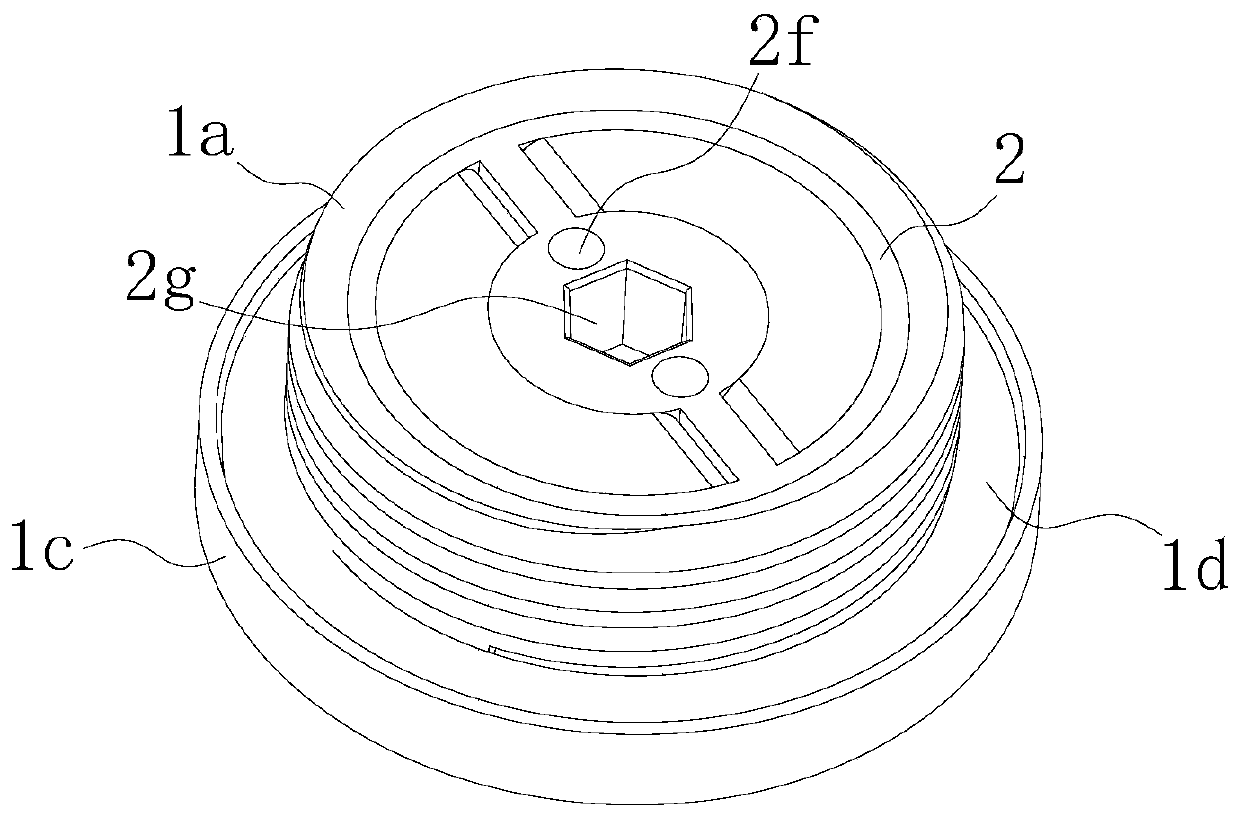

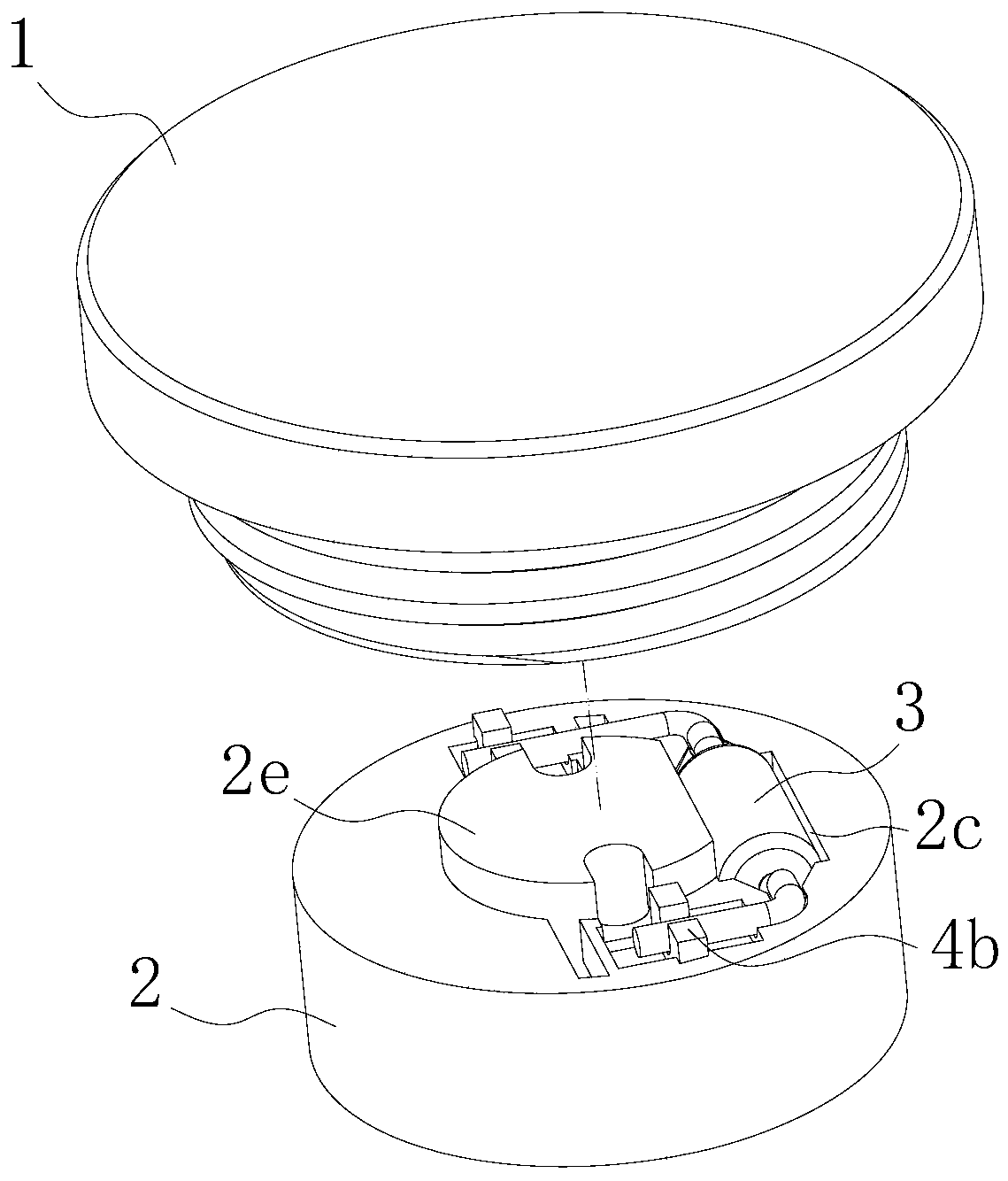

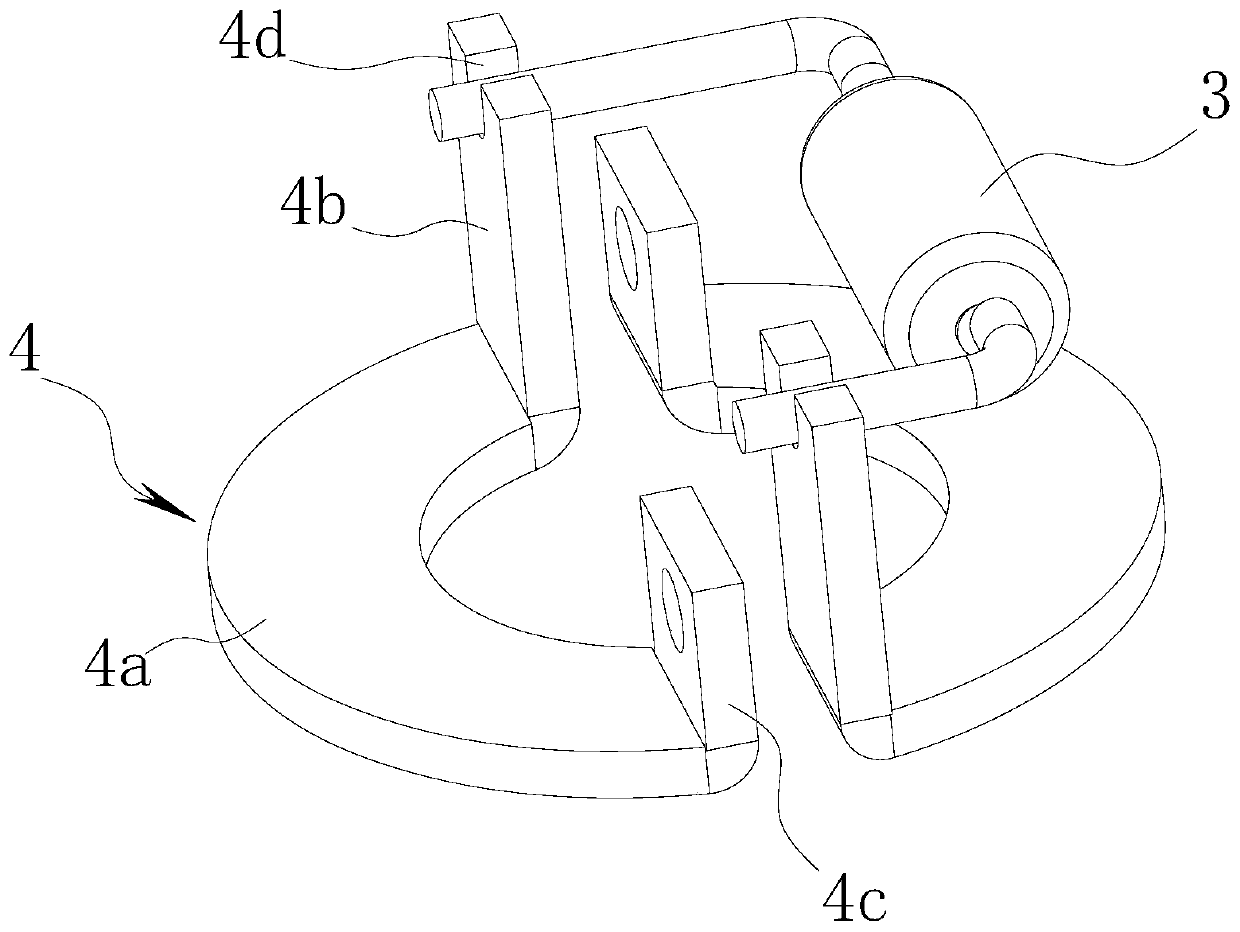

[0037] refer to Figure 1 to Figure 6 As shown, a temperature sensor packaging structure of the present invention includes a housing 1, the housing 1 is composed of a cylinder 1a open on one side and a sealing ring 1b formed at the sealing end of the cylinder 1a; inside the cylinder 1a A fixed frame 2 is provided, and a temperature sensing element 3 is interposed between the fixed frame 2 and the inner bottom of the cylinder 1a, and a conductive connector is provided on the fixed frame 2; the conductive connectors are respectively conductively connected to the temperature sensing element 3 and the external control panel. In this embodiment, the temperature sensing element is an NTC thermistor. Of course, other types of temperature sensing elements can be used to replace NTC thermistors as long as they can achieve the same temperature detection purpose.

[0038]Preferably, an external thread is formed on the outer wall of the cylinder 1a; a sealing sleeve 1c is integrally for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com