New energy self-cleaning solar panel

A solar panel, self-cleaning technology, applied in the direction of photovoltaic power generation, electrical components, photovoltaic modules, etc., can solve the problem that solar panels cannot be dusted, and achieve efficient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

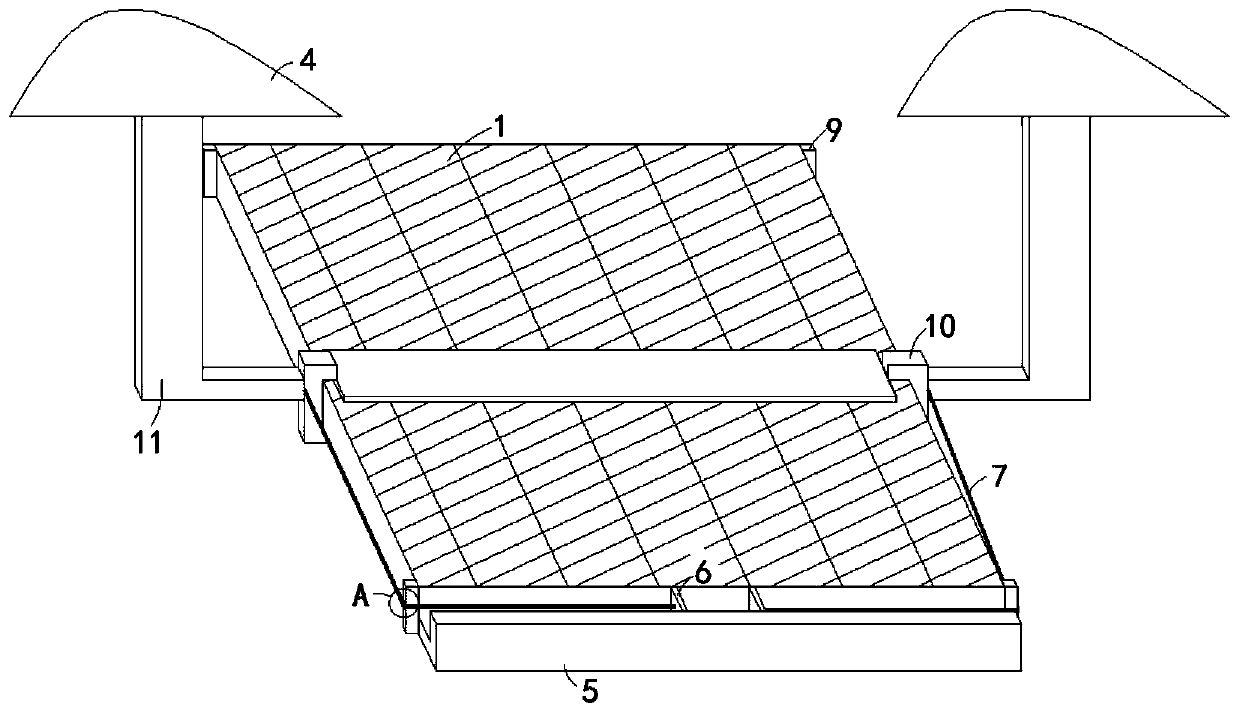

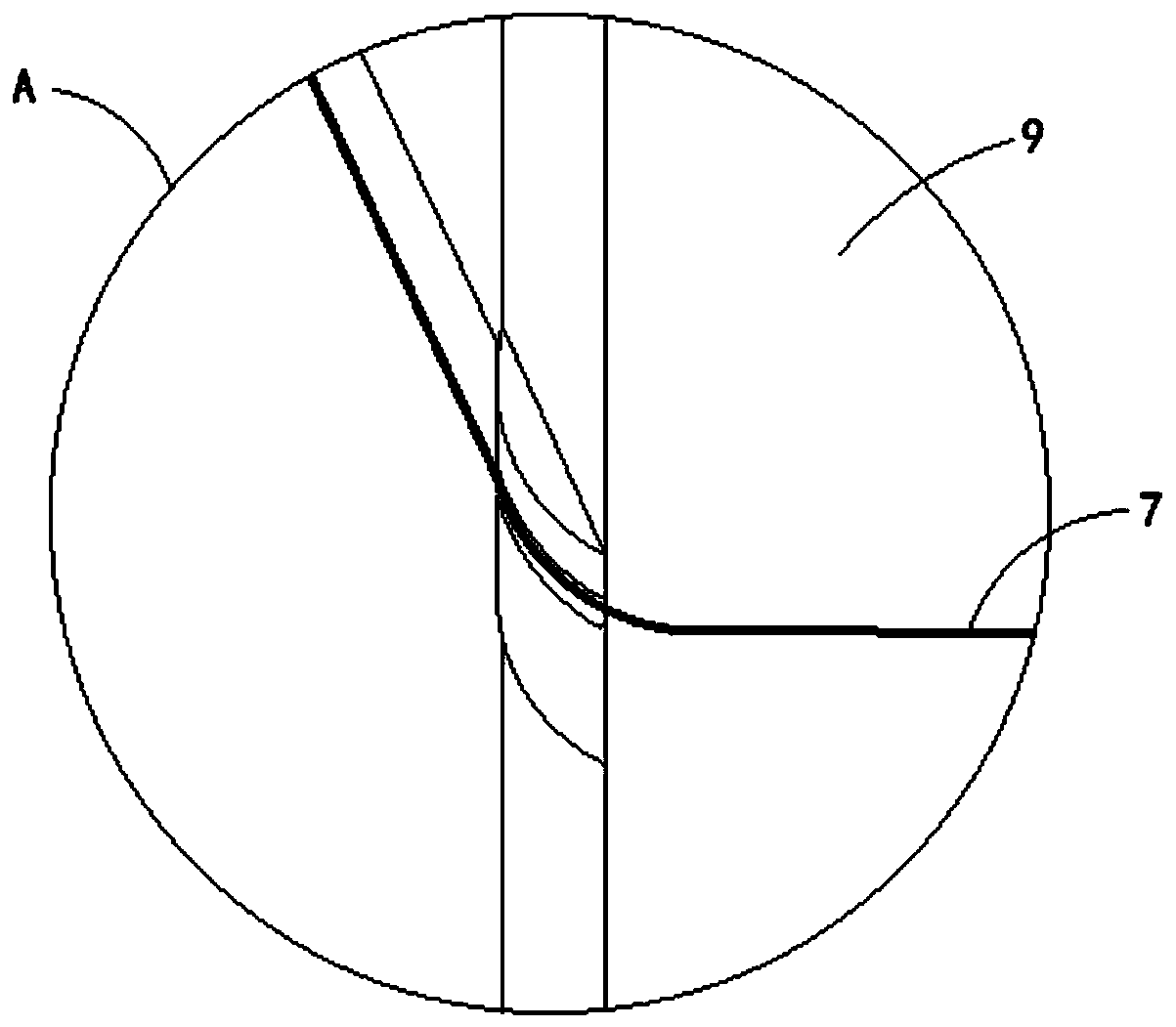

[0024] Such as Figure 1-4 As shown, a new energy self-cleaning solar panel includes a battery panel 1, the upper side wall of the battery panel 1 is slidably connected with a brush plate 2, and the left and right ends of the brush plate 2 are fixedly connected with a sliding mechanism 3, specifically Yes, the sliding mechanism 3 includes a U-shaped slider 10 engaged with the left and right sides of the battery panel 1, the U-shaped slider 10 is fixedly connected with an L-shaped connecting bar 11, and the upper end of the L-shaped connecting bar 11 is fixed to the wing plate 4 Connection, the other end of the sliding mechanism 3 is fixedly connected with a wing plate 4, which is in the shape of a wing, the upper edge is an upwardly arched arc line, and the lower edge is a horizontal line. , the wind will form a pressure difference on the upper and lower surfaces of the wing plate 4, that is, the pressure on the lower surface of the wing plate 4 is high, and the pressure on th...

Embodiment 2

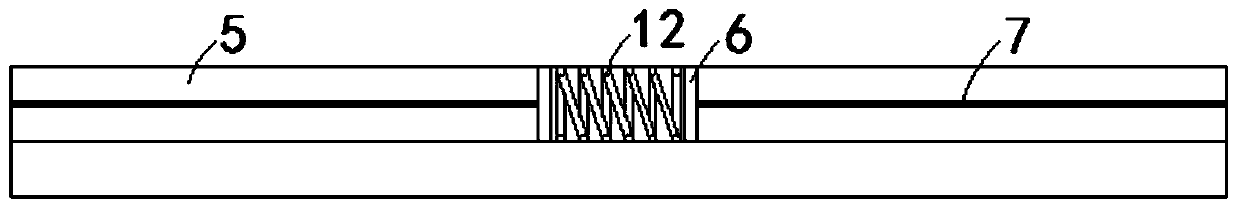

[0028] Such as Figure 5-6 As shown, the difference between this embodiment and Embodiment 1 is that the reset mechanism 8 includes an elastic bellows 13, and the two ends of the elastic bellows 13 are respectively fixedly connected to the opposite side walls of the two dust-scraping boards 6, and the dust-scraping boards 6 is provided with an air hole communicating with the elastic bellows 13.

[0029] In this embodiment, when the brush plate 2 moves upward, the dust-scraping plates 6 will be driven to move to both sides, and the elastic bellows 13 will be inflated at this time. The pulling of 13 moves toward the middle part of the dust storage tank 5, and the gas in the elastic bellows 13 can be pressed out in this process, and is sprayed in the dust storage tank 5 to remove the accumulated dust inside it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com