Chip taut manual pick-up device

A chip and stretch frame technology is applied in the field of chip tensioning and manual picking devices, which can solve the problems of poor separation of chips and membranes, waste of edge chips, missing corners and raised tooling, etc., so as to reduce chip damage costs and solve the The effect of waste and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

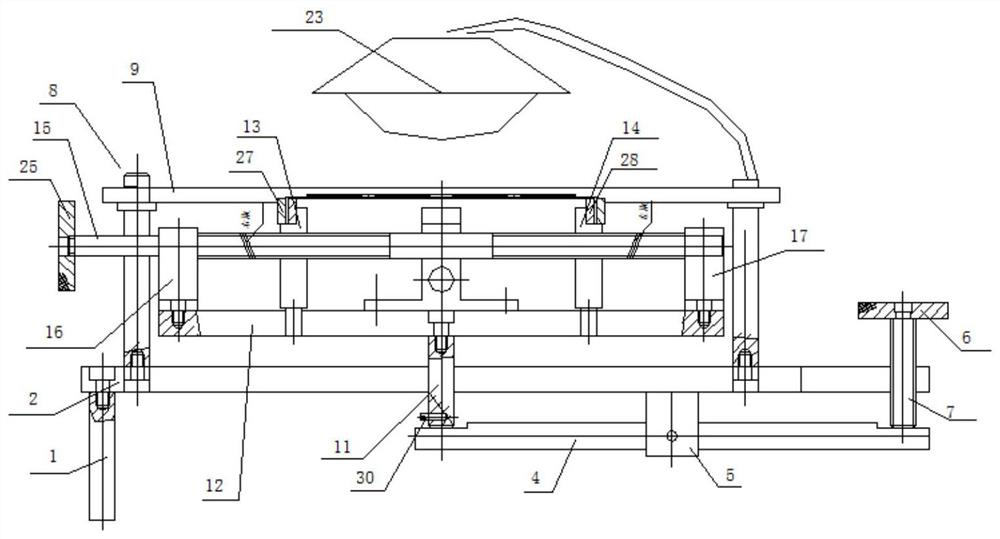

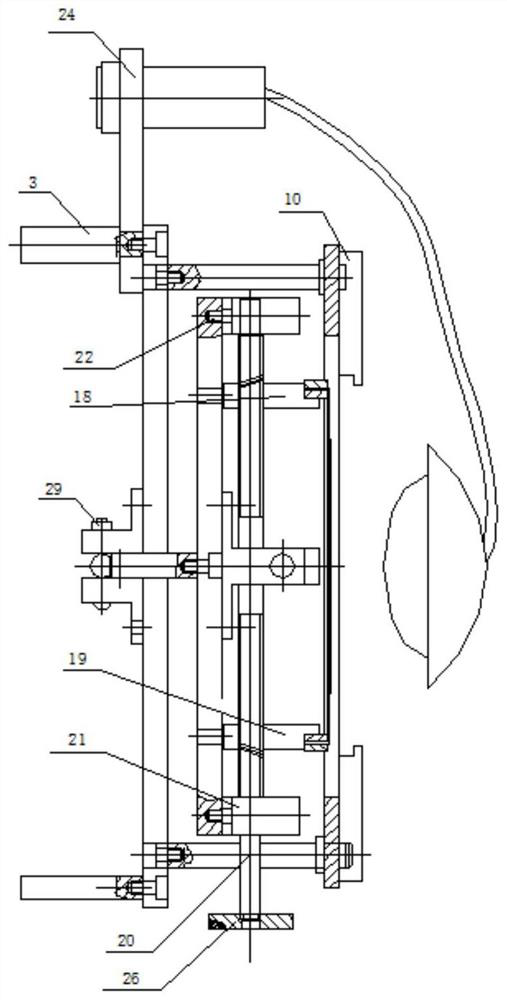

[0025] Such as Figure 1-2 , the device for manually picking up chips under tension in this embodiment is characterized in that it includes a lower base plate 2, a lower base plate support I1, a lower base plate support II3, a lever 4, a lever frame 5, a lever adjustment nut 6, a lever adjustment bolt 7, Upper fixed plate pillar 8, upper fixed plate 9, adjustable compression block 10, height adjustment bar 11, lower frame bottom plate 12, right-handed bracket I13, left-handed bracket I14, tensioning shaft I15, shaft support bracket I16, shaft support bracket II17, right-handed bracket I18, left-handed bracket I19, tension shaft II20, shaft support bracket III21, shaft support bracket IV22, oven lamp 23, oven lamp fixing plate 24, tension shaft nut I25, tension shaft nut II26, screw shaft 29. Height limit screw 30

[0026] The lower floor pillar I1 is installed on the lower end of the lower floor 2 and fixed by screws; the lower floor pillar II3 is installed on the lower floor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com