Single-free-surface combined blast hole broaching blasting method

A technology of blasting and slotting, which is applied to the field of single-free-surface combined blasting slotting blasting, can solve the problems of large amount of charge in a single blasting section, adverse effects of surrounding rock mass and facilities and equipment, etc., to achieve blasting vibration reduction, reduce Blasting vibration effect, the effect that is conducive to rock crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

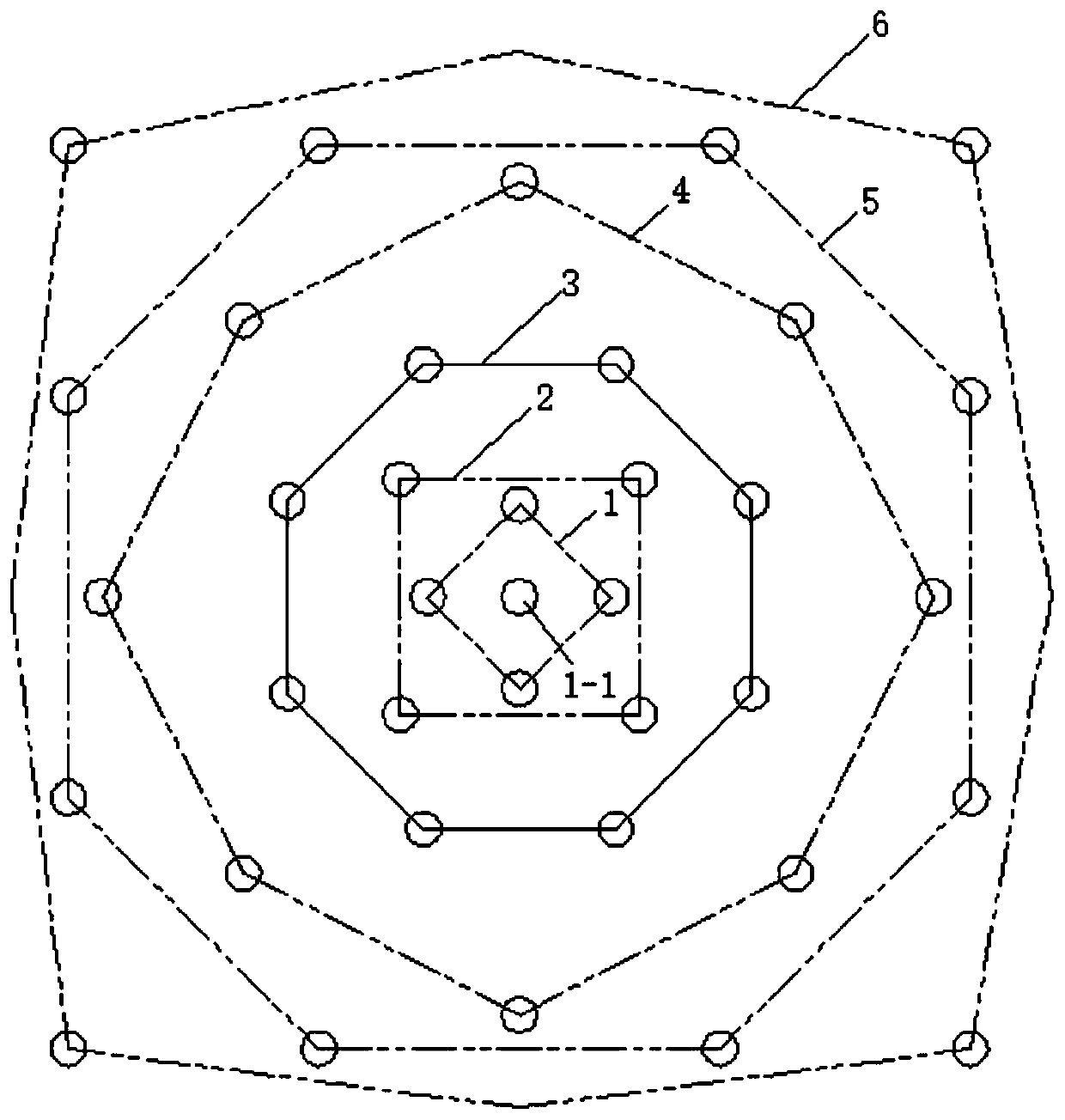

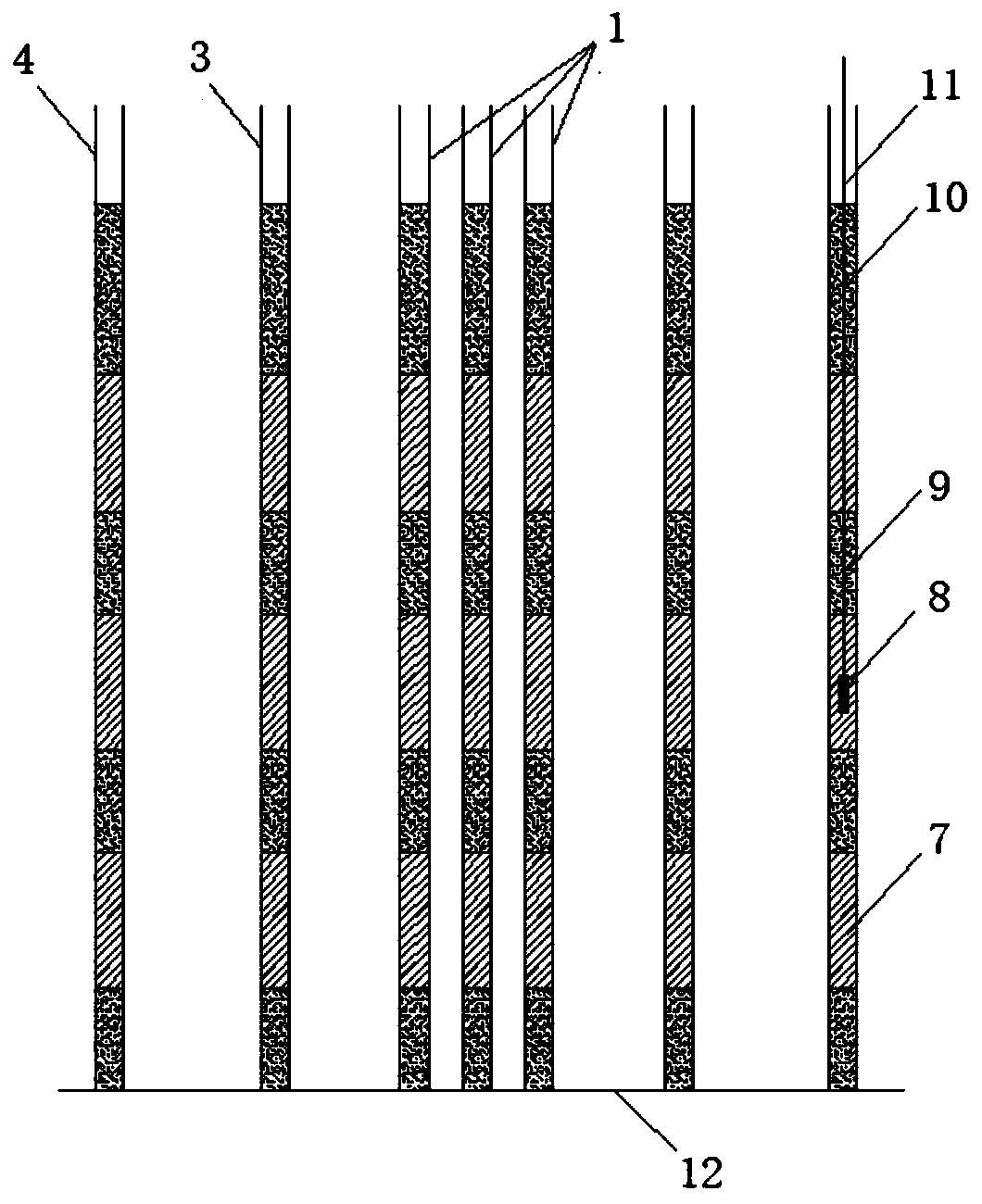

[0027] see Figure 1-3 , the figure shows the specific implementation of the single free surface combined blast hole slotting blasting method of the present invention.

[0028] Specific as figure 1 As shown, in this embodiment, six circles of combined blastholes are arranged in the groove blasting area. The arrangement steps of combined blastholes are as follows: firstly, a central blasthole 1-1 is set in the middle of the slotting blasting area, and a circle of four blastholes arranged in a square orientation is set around the center blasthole, and the above five blastholes form The first circle of combined blastholes 1; outside the first circle of combined blastholes 1, a circle of four blastholes arranged in a square orientation is set around the center blasthole 1-1 to form a second circle of combined blastholes 2; then Three circles of combined blastholes arranged in regular octagonal orientations are gradually set outward with the center blasthole 1-1 as the center, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com